Inspection system of traction type inspection robot

A technology of inspection robots and inspection systems, applied in the field of inspection systems, can solve problems such as manual inspection safety hazards, achieve the effect of improving accuracy, improving automation, and realizing fewer or no-man operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

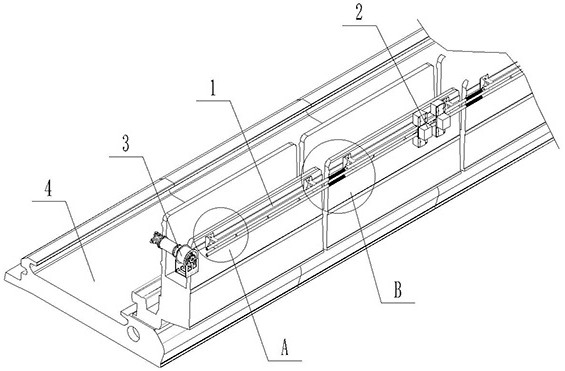

[0027] Such as Figure 1 to Figure 11 As shown, the inspection system of a traction inspection robot of the present invention includes a general track structure 1, a patrol robot body 2 and a driving device 3, and the general track structure 1 and the driving device 3 are all arranged on the scraper machine 4 Above, the inspection robot body 2 is movably arranged on the general track structure 1, and the inspection robot body 2 can move along the general track structure 1 under the traction of the driving device 3 through the steel wire rope, and patrols the fully mechanized mining face. check.

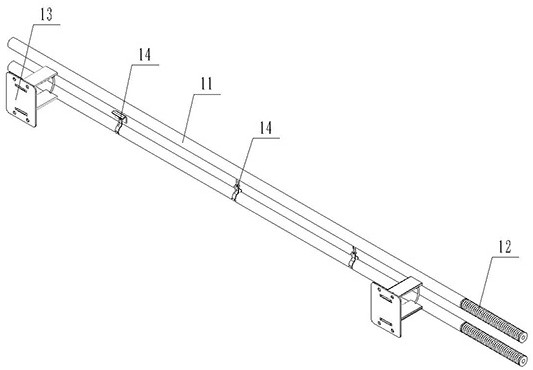

[0028] The overall track structure 1 includes: a plurality of track bodies 11, first elastic connectors 12, support frames 13 and limit blocks 14, one side of the support frames 13 is fixedly arranged on the scraper machine 4, and the support The other side of the frame 13 is provided with two baffles 15 parallel up and down, one end of the two baffles 15 is fixedly arranged on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com