Longwall mining machine and a linepan section

A mining machine and longwall technology, applied to conveyors, cutting machinery, slitting machinery, etc., can solve problems such as production delays, poor loading characteristics of the middle slot, and inability to load cut materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Before describing in detail any individual embodiments of the invention, it is to be understood that the invention is not limited in application to the details of construction and the arrangement of components set forth in the following description and shown in the drawings below. The invention is capable of other independent embodiments and of being practiced or carried out in various ways.

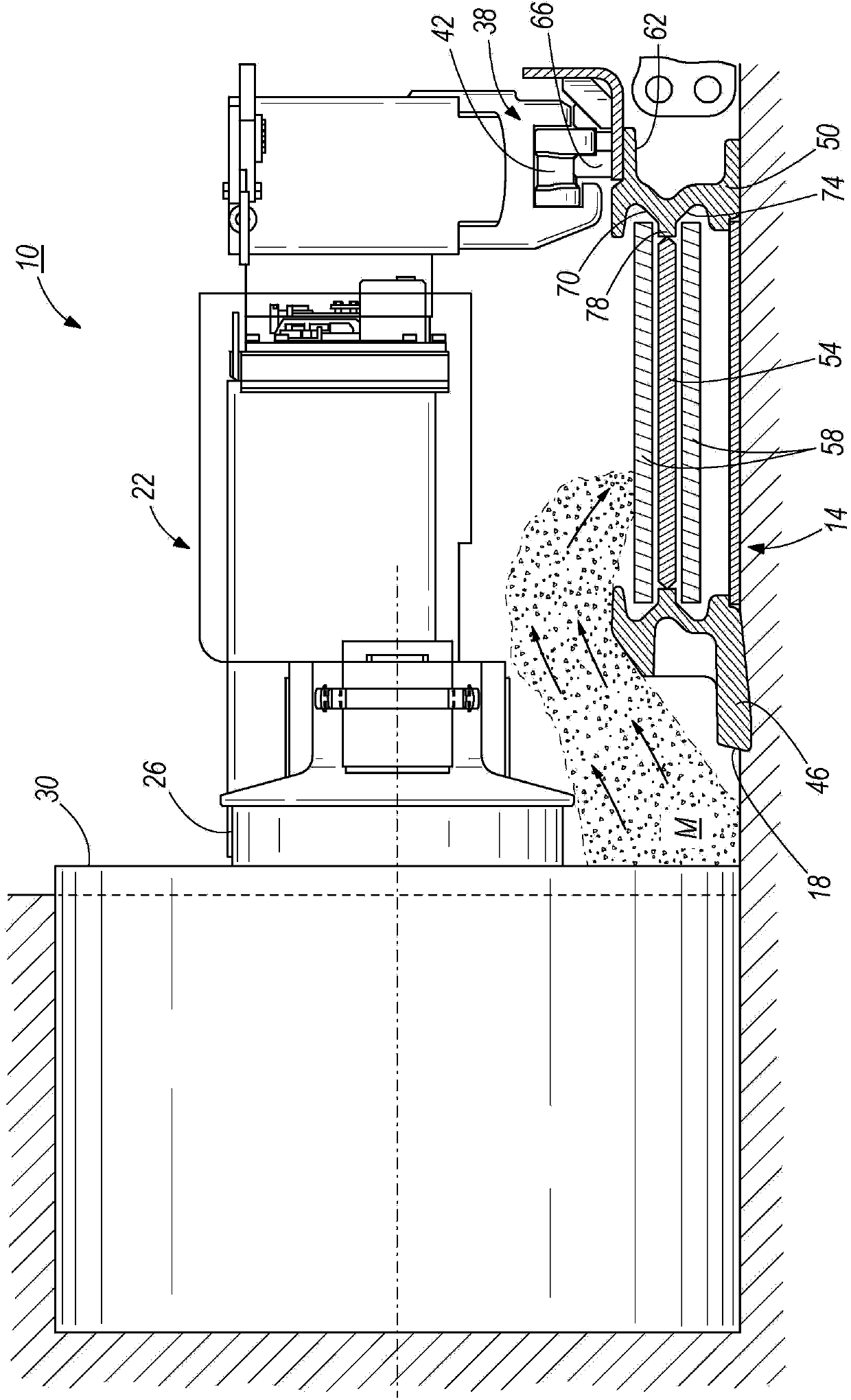

[0021] figure 1 A longwall mining machine 10 is shown comprising an Armored Conveyor (AFC) 14 having a plurality of central trough sections 18 (one shown), and a coal mining drum Machine 22. The drum shearer 22 includes: a cutting drum 26 for cutting material M (eg, coal) from a mining face 30; and a shoe 34 (see Figure 7 ), the shoe 34 straddles the AFC 14 to support the shearer 22 . Such as figure 1 As shown in , traction assembly 38 includes drive sprocket 42 for pulling drum shearer 22 along mining face 30 .

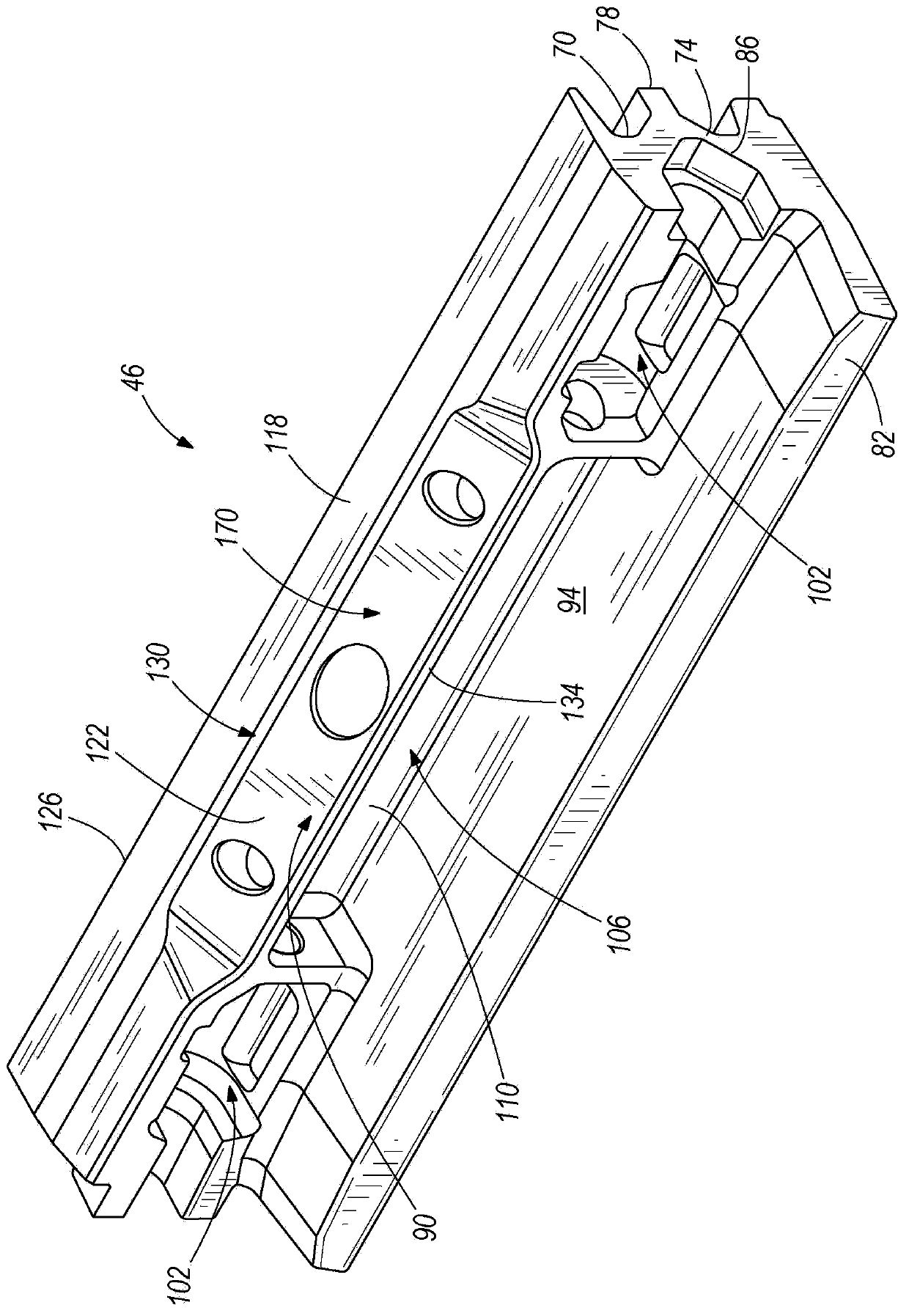

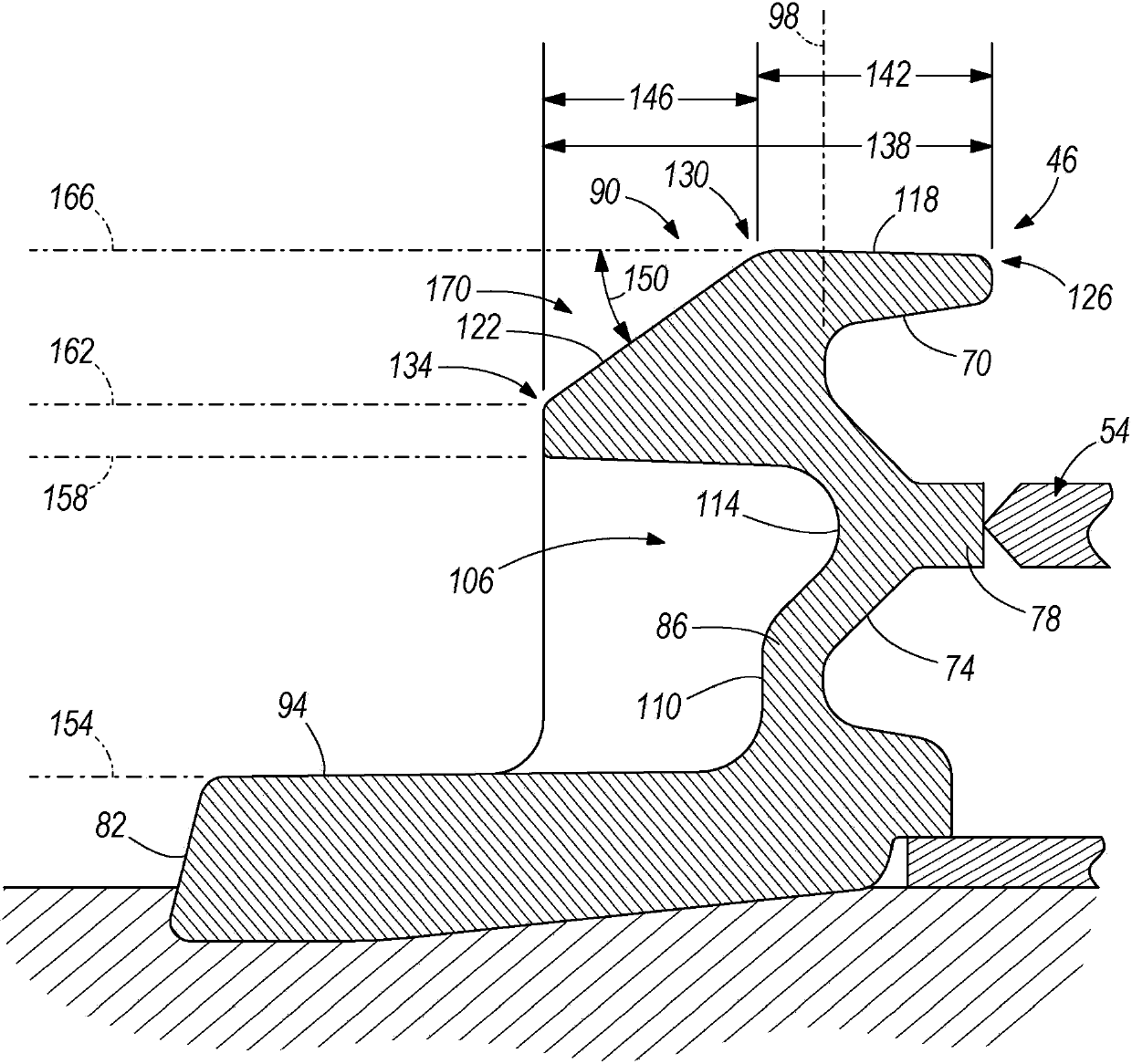

[0022] Each mid-trough section 18 of the AFC 14 includes a fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com