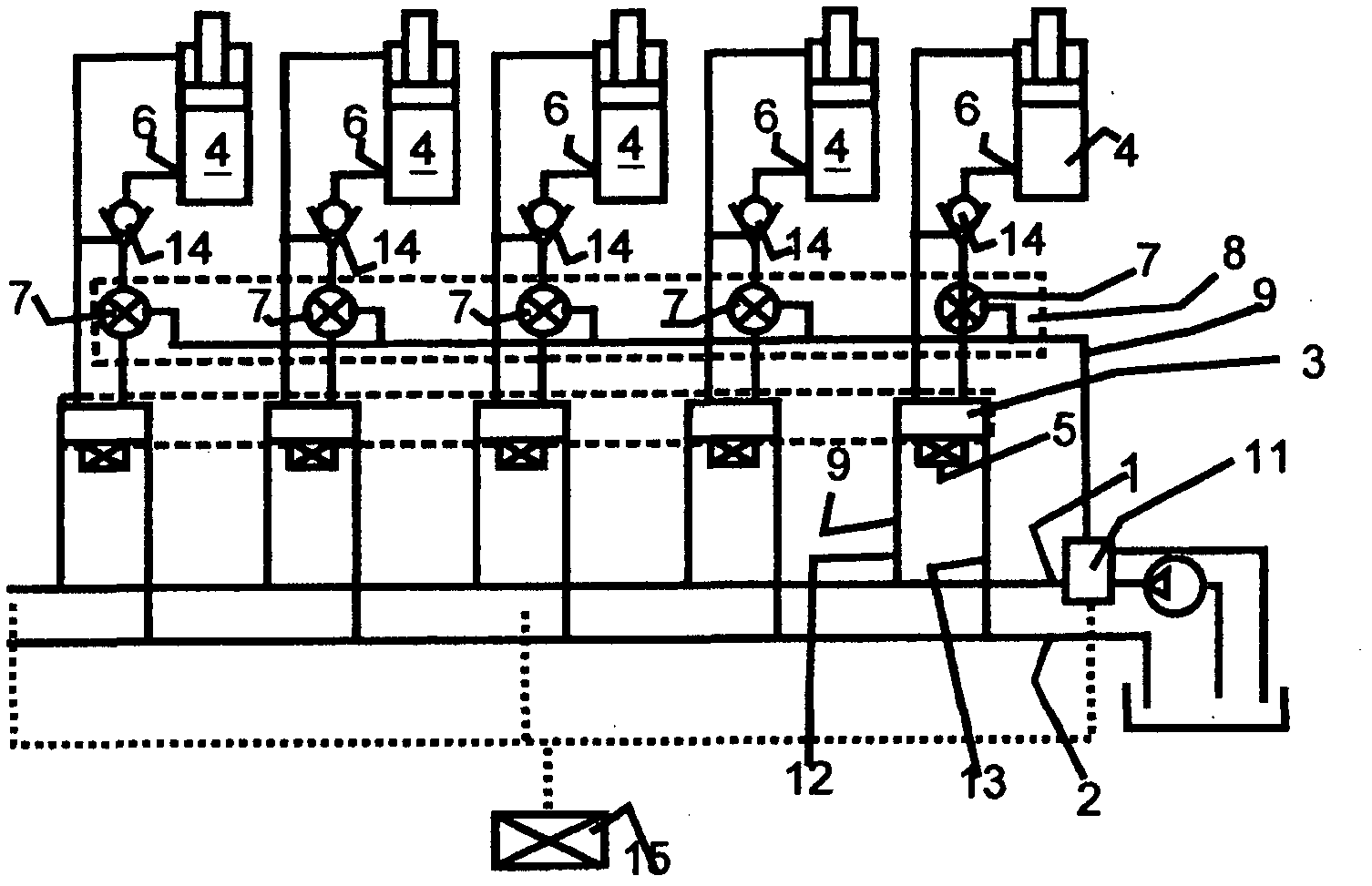

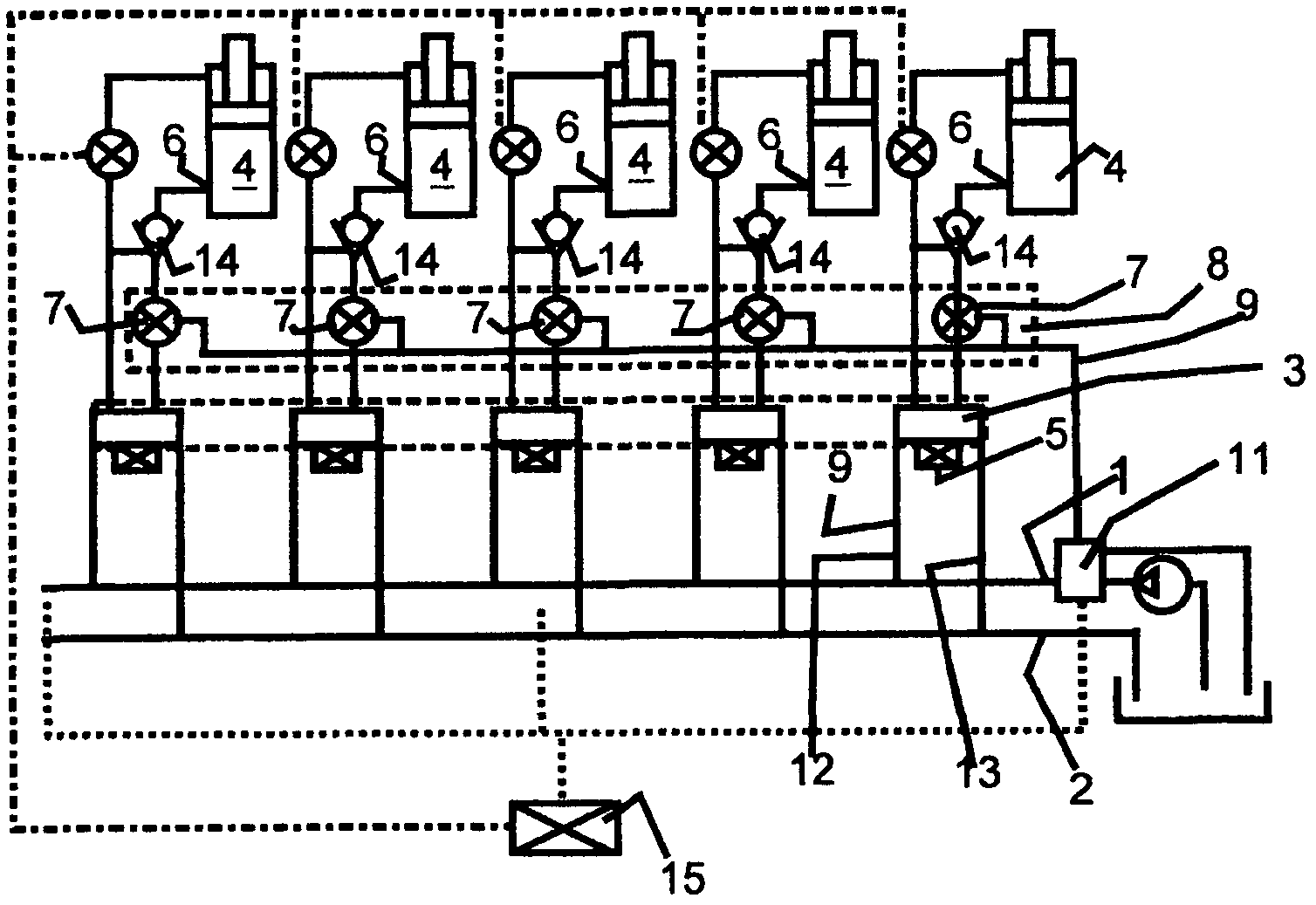

Hydraulic circuit for longwall mining

A technology of hydraulic circuit and working surface, applied in the field of hydraulic circuit, can solve the problems of undesired opening and backflow blocking, and achieve the effect of high cost performance, high cost performance and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

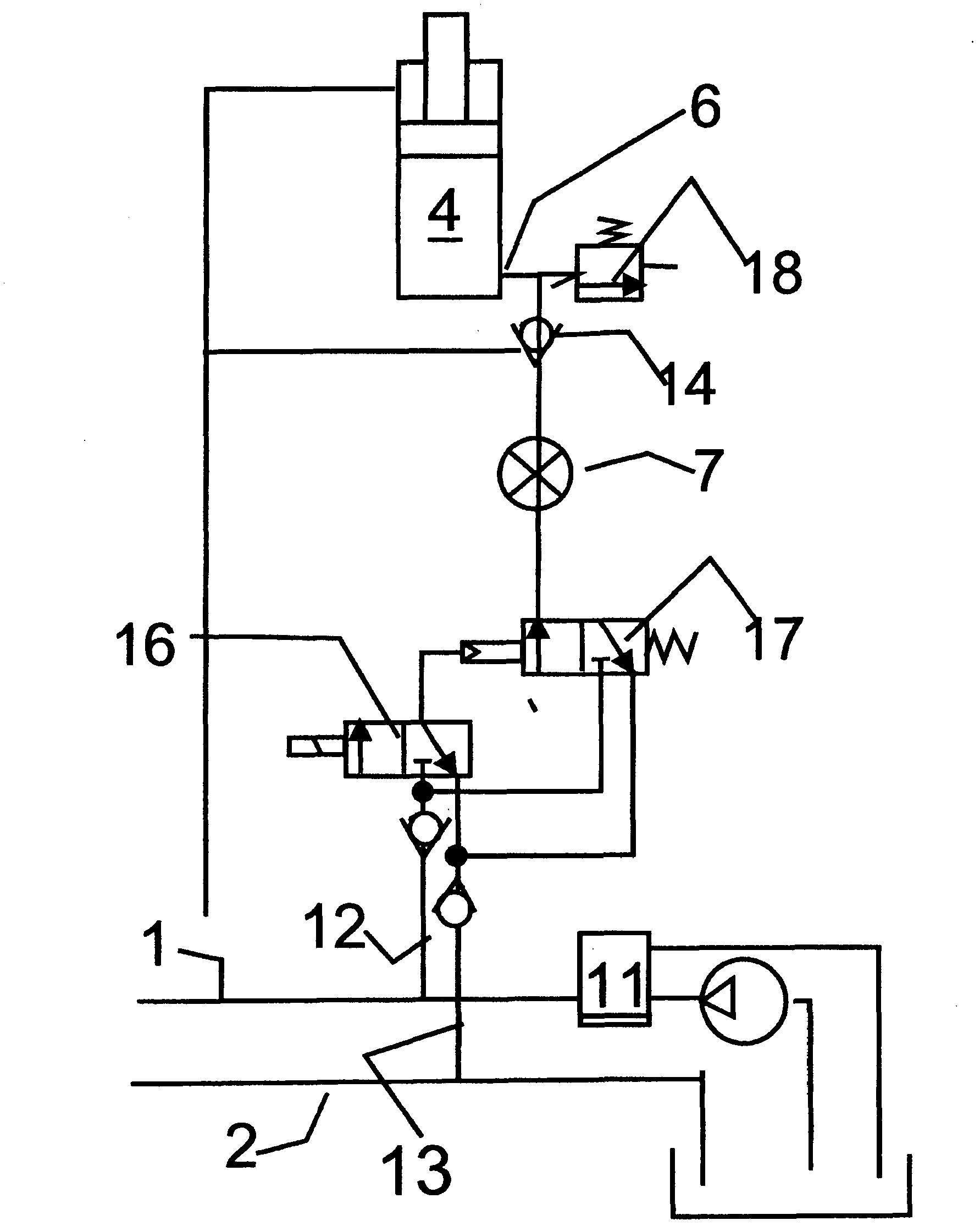

[0029] Basically, the connection of each force applicator to the pump accumulation line of the face (pump branch) is via a non-return valve configured as a blockable block between the output of the force applicator, which is loaded by the mountain pressure, and the hydraulic control device 5 The load support valve 14 is blocked, so that when the pump pressure is canceled or cut off, the load pressure of the force applicator falls on the check valve which is sealed closed. However, the non-return valve 14 can be blocked by hydraulic presetting by the system pressure when the pressure difference between the load pressure and the presetting pressure falls below a value predetermined by the valve design. The non-return valve 14 is switched hydraulically, so that when the hydraulic pressure is cut off, the working space of the force applicator is connected to the return flow accumulation line via the starter 6 and the return flow branch. Such a shut-off non-return valve is known, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com