Method for controlling a cutting extraction machine

A mining machine, cutting-type technology, applied in the field of controlling cutting-type mining machines, can solve problems such as hindering thermal radiation measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

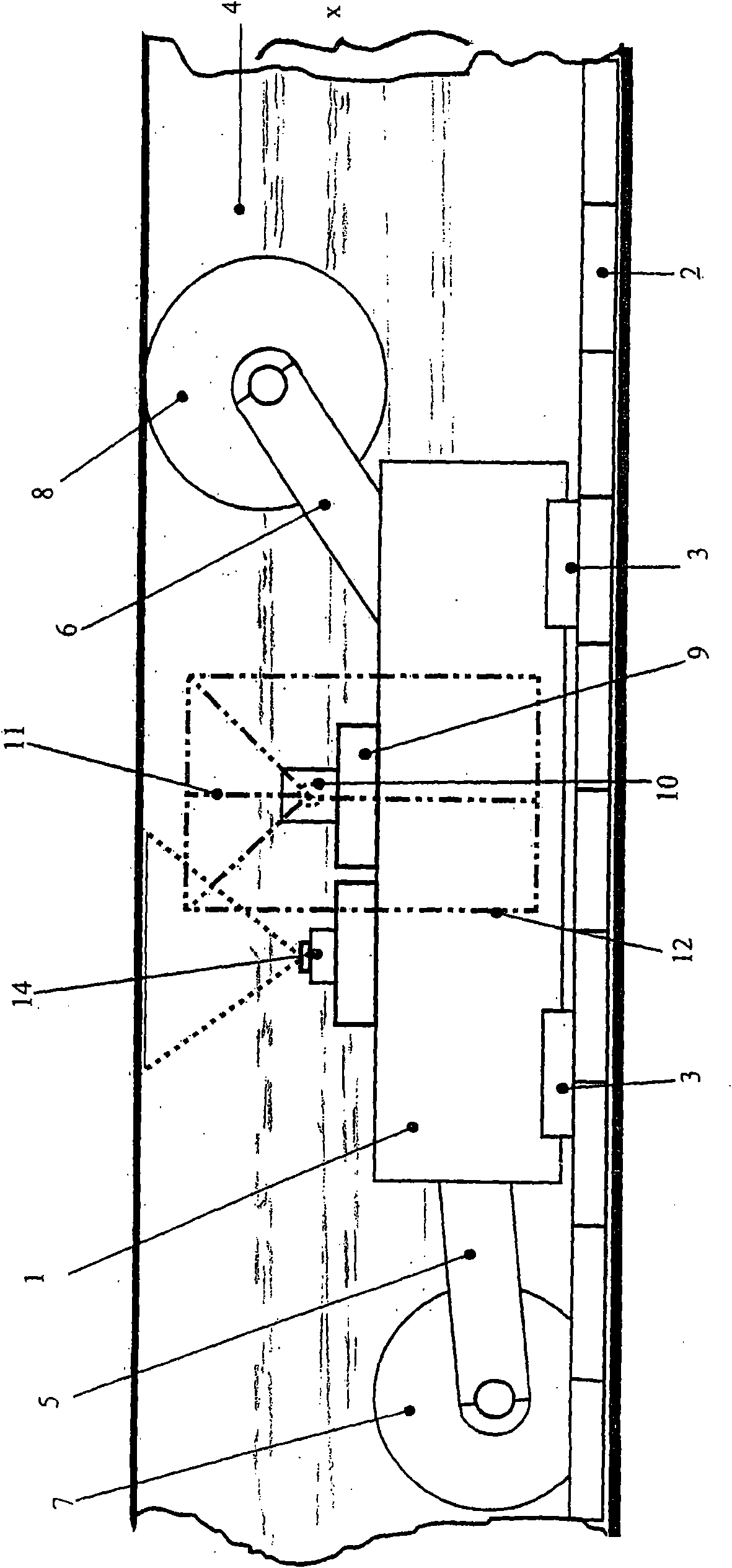

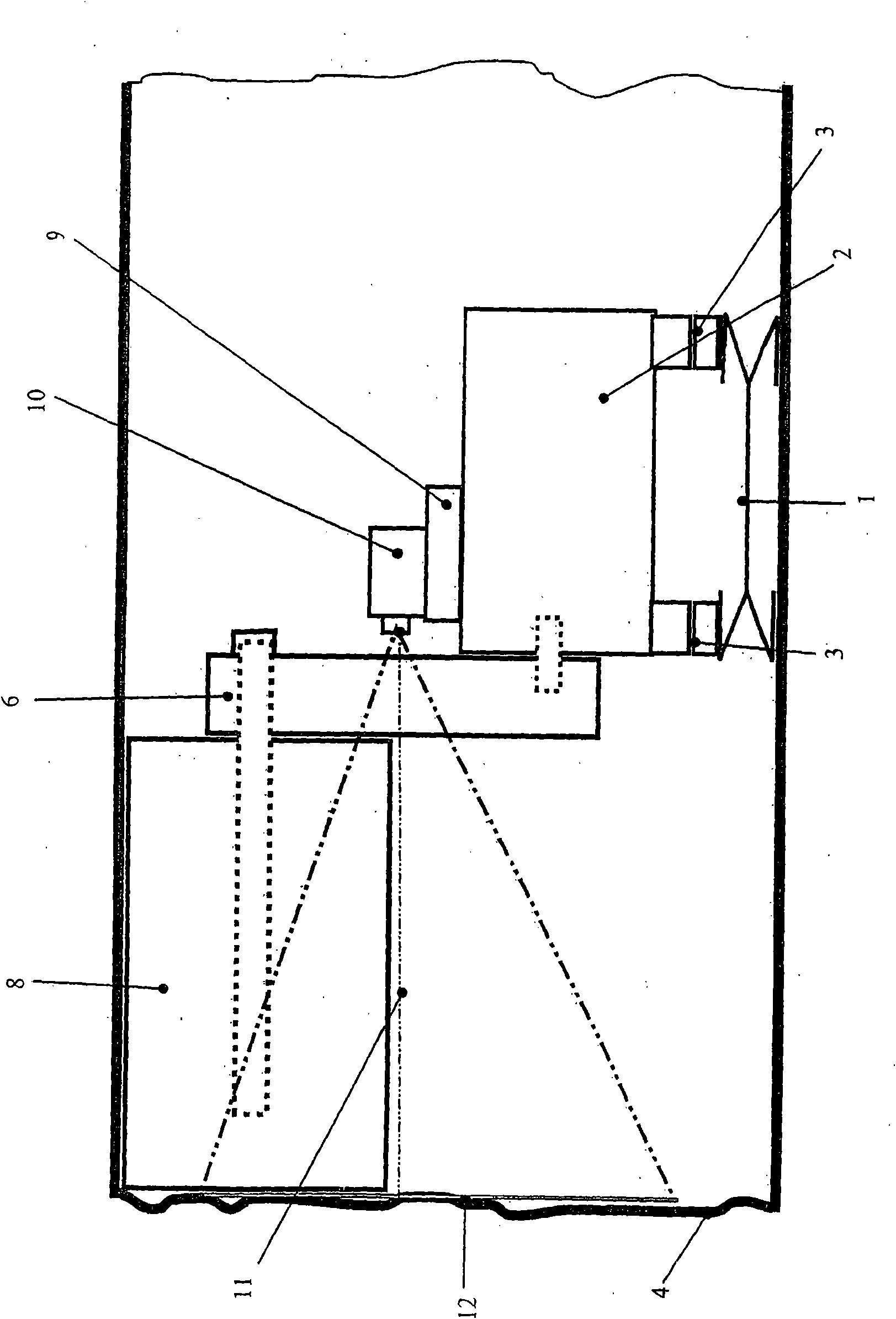

[0023] In the drawings, the body of the cutting mining machine, here the drum shearer, is marked with the reference number 1 . This body is provided with roller type slide shoes 2 below, and these roller type slide shoes can move along the working front wall 4 of the working face on the working face conveyor 3. The face conveyor 3 is thus at the same time a track for the cutting miner.

[0024] At the front and rear ends in the direction of travel, pivoting arms 5 and 6 are supported on the body 1, and these pivot arms 5 and 6 carry cutting drums 7 and 8, respectively, which are equipped with cutting drums on the circumference. tool.

[0025] Approximately in the middle of the body 1 there is a camera support 9 on which is mounted an infrared camera 10 whose optical axis 11 extends perpendicularly to the working front wall 4 .

[0026] Infrared camera 10 collects a rectangular measurement field 12 on the front wall of the work, and the measurement field is figure 1 Shown wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com