Integral high-strength flexible support method of roadway at large-inclined angle coal-seam longwall mining section

A technology with a large inclination angle and high strength, which is applied in mining equipment, earthwork drilling, pillars/brackets, etc. It can solve problems such as inability to guarantee stability, restrict production and efficiency of working faces, and instability, and achieve mining and flexible support The method is simple, the economic and social benefits are significant, and the effect of use is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

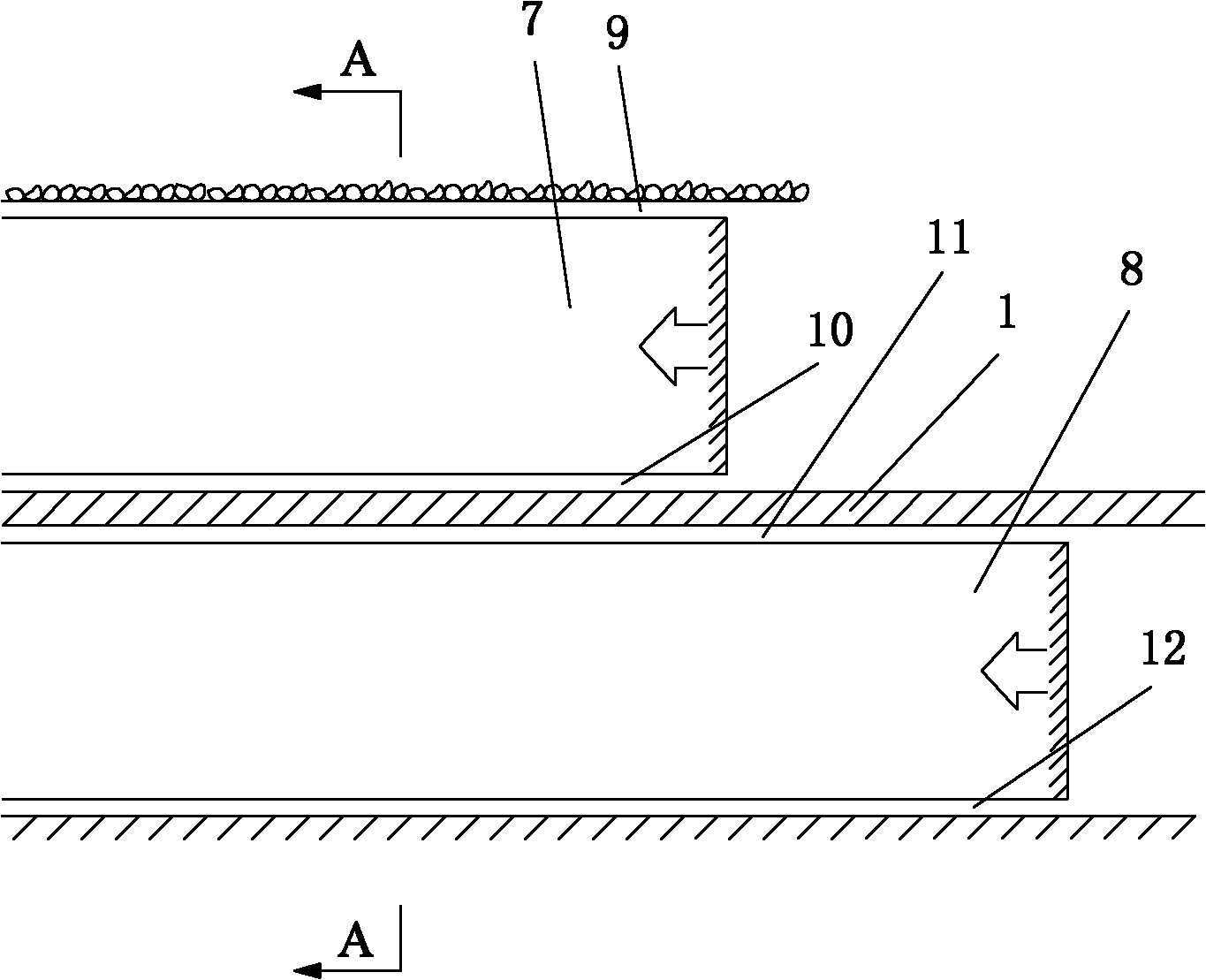

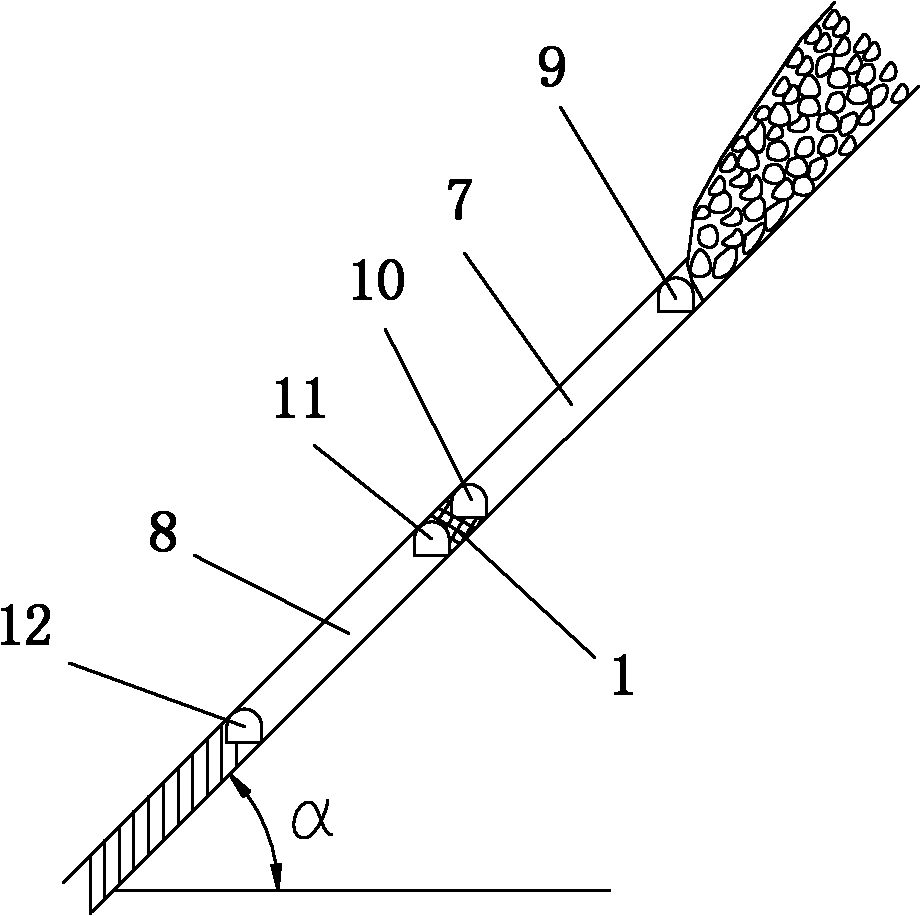

[0053] In this embodiment, two coal mining sections / working faces are arranged from top to bottom in the same stage of the mined high-dip angle coal seam and N=2, and the two coal mining sections / working faces in the same stage are respectively upper The coal mining section / working face 7 and the lower coal mining section / working face 8 located below the upper coal mining section / working face 7, the upper and lower sections of the upper coal mining section / working face 7 are along the large inclination angle The length direction of the coal seam is respectively provided with a return air leveling 19 and a transport leveling 10, and the upper and lower parts of the lower coal mining section / working face 8 are respectively provided with a return air leveling along the length direction of the large dip angle coal seam. 211 and 212 Transportation Level Lane, see details figure 2 and image 3 . Correspondingly, the coal mining section / working face 7 is the first coal mining sect...

Embodiment 2

[0068] In this embodiment, the difference from Embodiment 1 is that N coal mining sections / working faces are arranged from top to bottom in the same stage of the mined high dip angle coal seam, and N>2.

[0069] In this embodiment, the difference from Embodiment 1 is that the upper coal mining section / working face 7 (ie the first coal mining section / working face) and the currently mined lower coal mining area are described in step 2. Section / working face 8 (that is, the second coal mining section / working face) forms an integral working face, that is, after the mining process of the second coal mining section / working face is completed, the Mining is carried out in multiple mining sections / faces below the face.

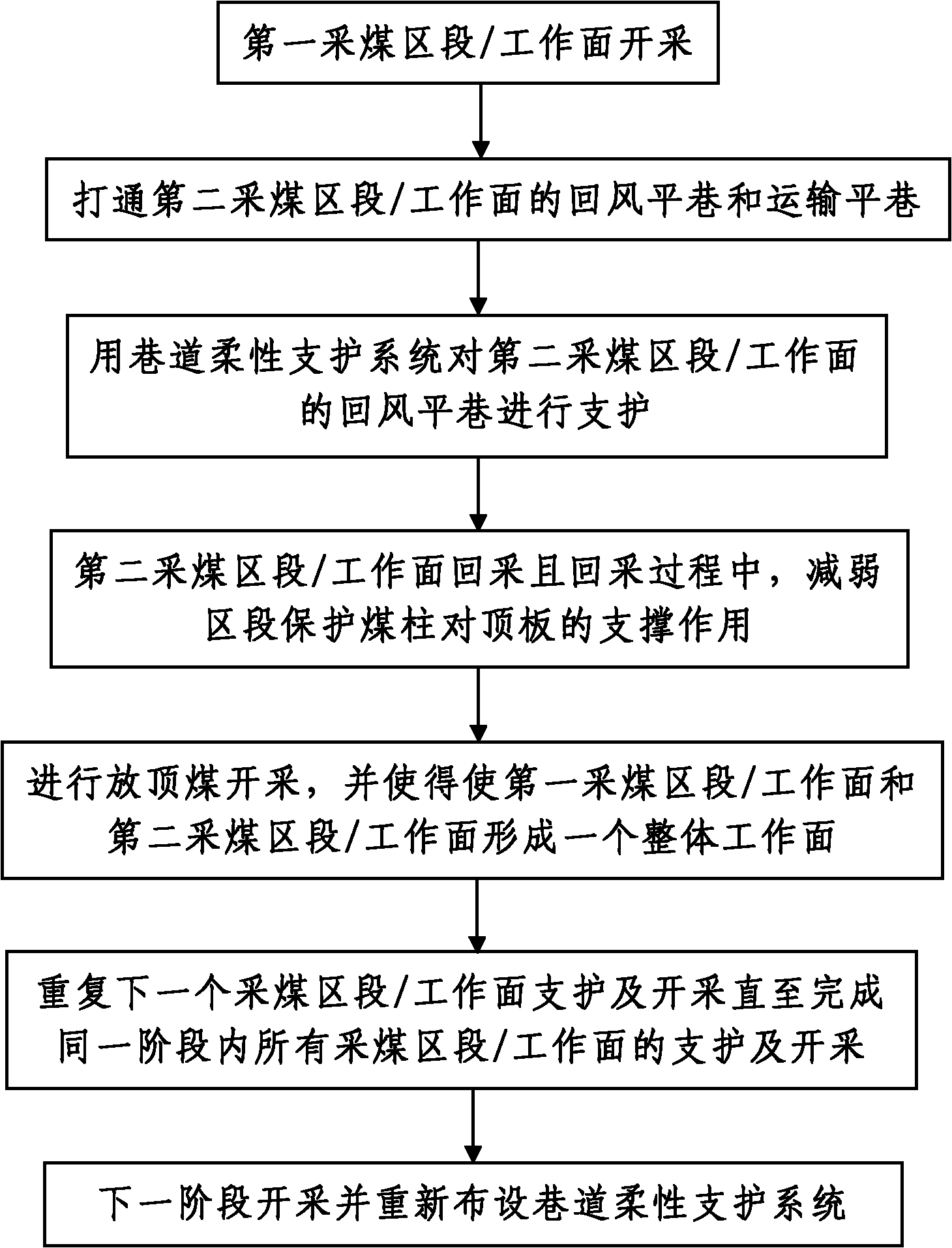

[0070] In this embodiment, the following steps are included when mining N coal mining sections / working faces in the same stage of the mined high-dip coal seam:

[0071] Step 1: The first coal mining section / working face is mined, and the mining method is the same as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com