Method for controlling longwall mining operations

A longwall, operation technology, applied in mining equipment, earthwork drilling, cutting machinery, etc., can solve problems such as damage to intentional operating mechanisms during operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

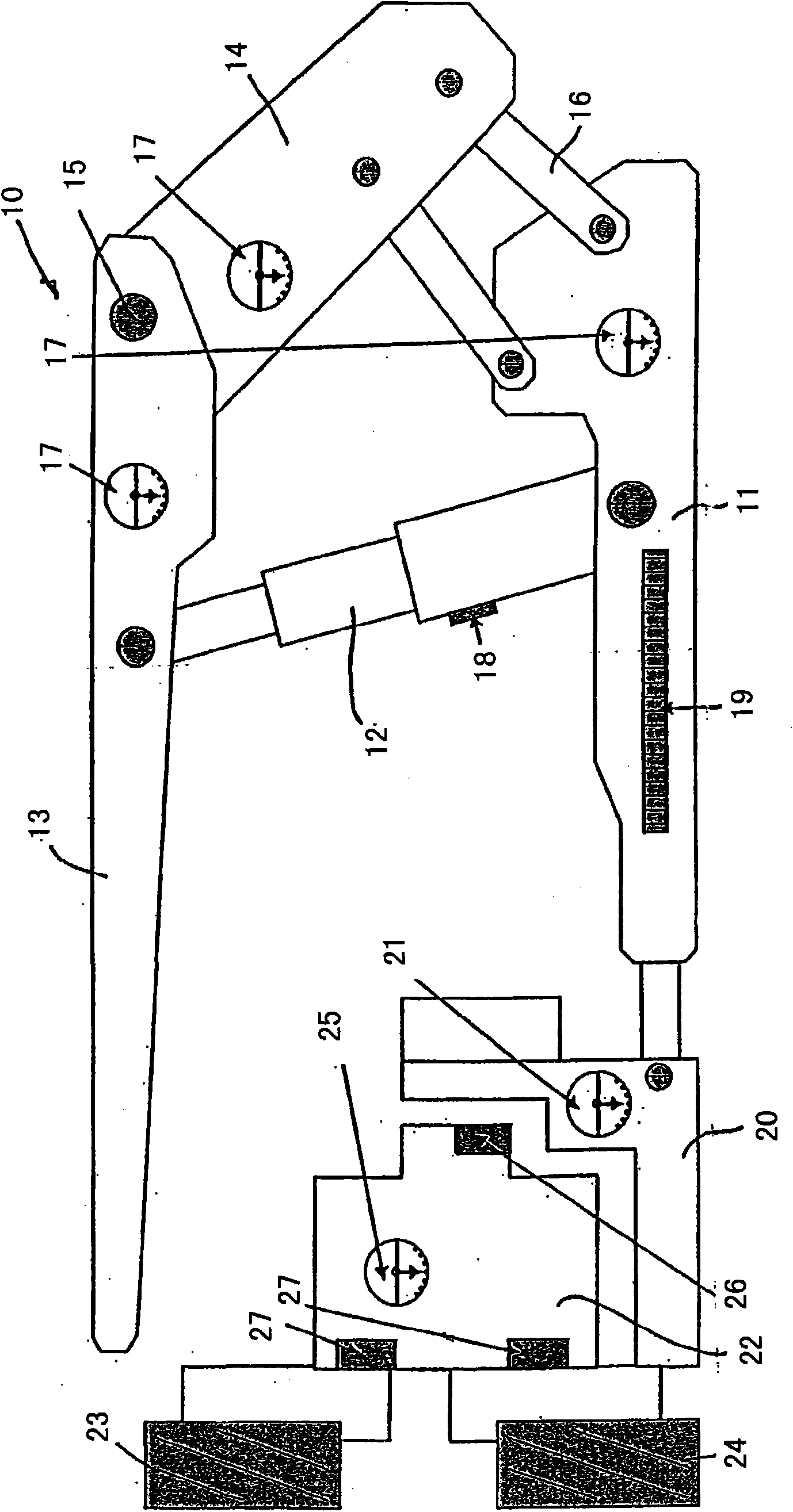

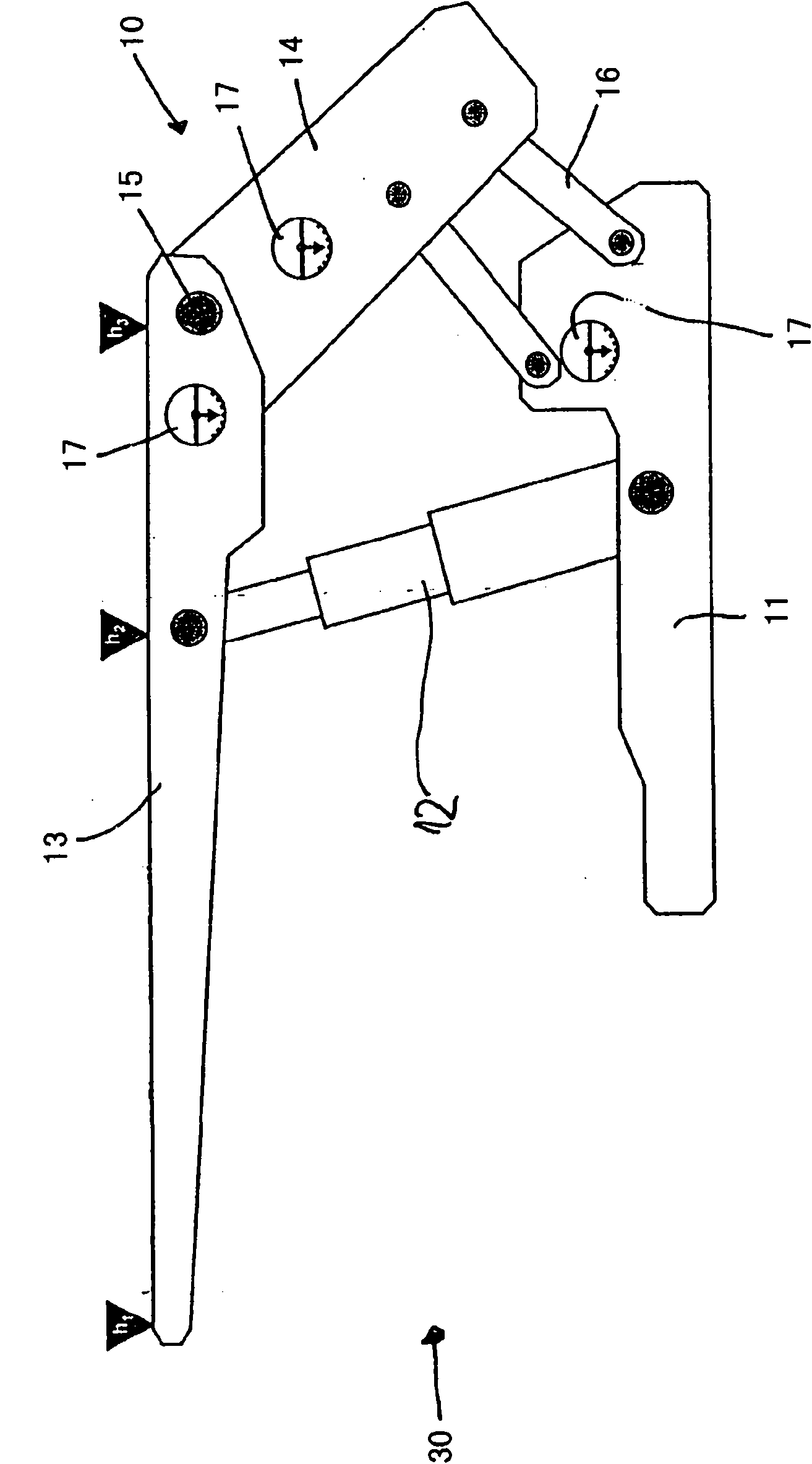

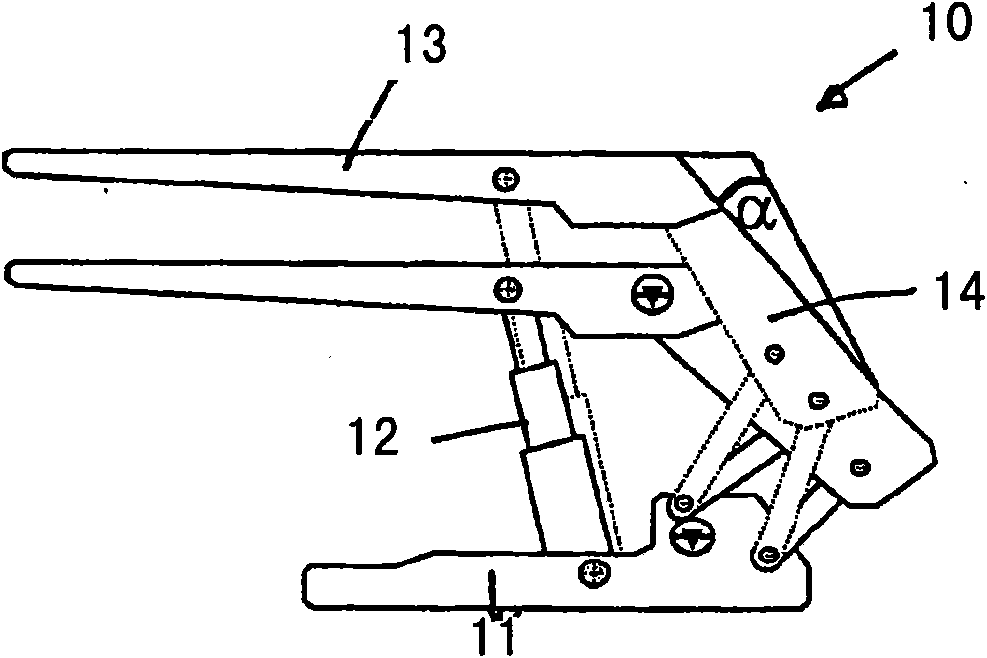

[0033] figure 1 The shown longwall installation (Strebausrüstung) firstly comprises a cover support frame 10 with a bottom carriage (Bodenkufe) 11, on which two struts 12 are arranged in a parallel configuration, on which figure 1 Only one support can be seen in FIG. 2 and this supports a top beam (Hangenkappe) 13 at its upper end. At its front end (left) the head beam 13 protrudes in the direction of the still-described shearer, while a goaf shield (Bruchschild) 14 is hinged to the rear end (right) of the head beam 13 by means of a hinge 15 , wherein the goaf shield frame is supported by two support guide rods 16, and the two support guide rods 16 are arranged on the bottom sliding frame 11 in a side view. In the illustrated embodiment, three inclination sensors 17 are provided on the shield support frame 10, namely the inclination sensor 17 on the bottom carriage 11, the inclination sensor 17 near the hinge 15 in the rear area of the top beam 13, the inclination sensor 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com