Variable pressure-resistant cascading liquid piston device

A liquid piston, cascading technology, applied in the direction of variable capacity pump components, liquid variable capacity machines, machines/engines, etc., can solve the problems of low efficiency, increased cost, and inability to provide gas temperature control, etc., to reduce pipelines Switching, reducing project cost, and remarkable economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention provides a variable pressure-resistant cascaded liquid piston device. The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

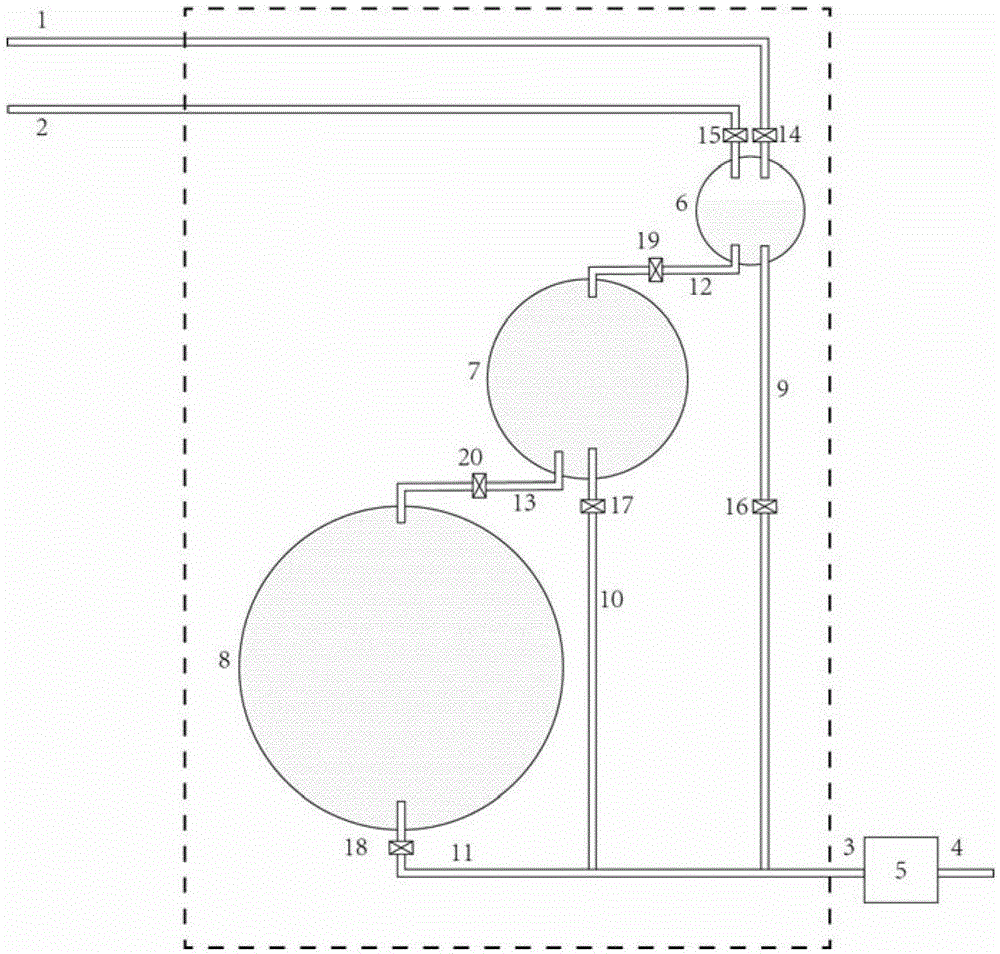

[0038] figure 1 Shown is a general structure diagram of a liquid piston device. The three pressure vessels 6, 7 and 8 with different pressure resistance values in the device are connected to each other to form a pressure vessel group, in which the pressure vessel 6 has the highest pressure resistance level and the smallest volume; the pressure vessel 8 has the lowest pressure resistance level and the largest volume . There are fast liquid pipelines 9, 10 and 11 at the bottom of the three pressure vessels respectively, and the fast liquid pipelines are connected with the external hydraulic equipment 5. Each pipeline is equipped with a controllable valve. Through the switch control of the valve, the combination of pressure vessels with different pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com