Heat dissipating device with independent air channels

A technology of a heat dissipation device and an air duct is applied in the field of heat dissipation of a heating power unit, which can solve the problems that the surface of the radiator cannot be fully passed, the applicability of high-power equipment is poor, and the cost is high. Effects that are easy to use in the field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

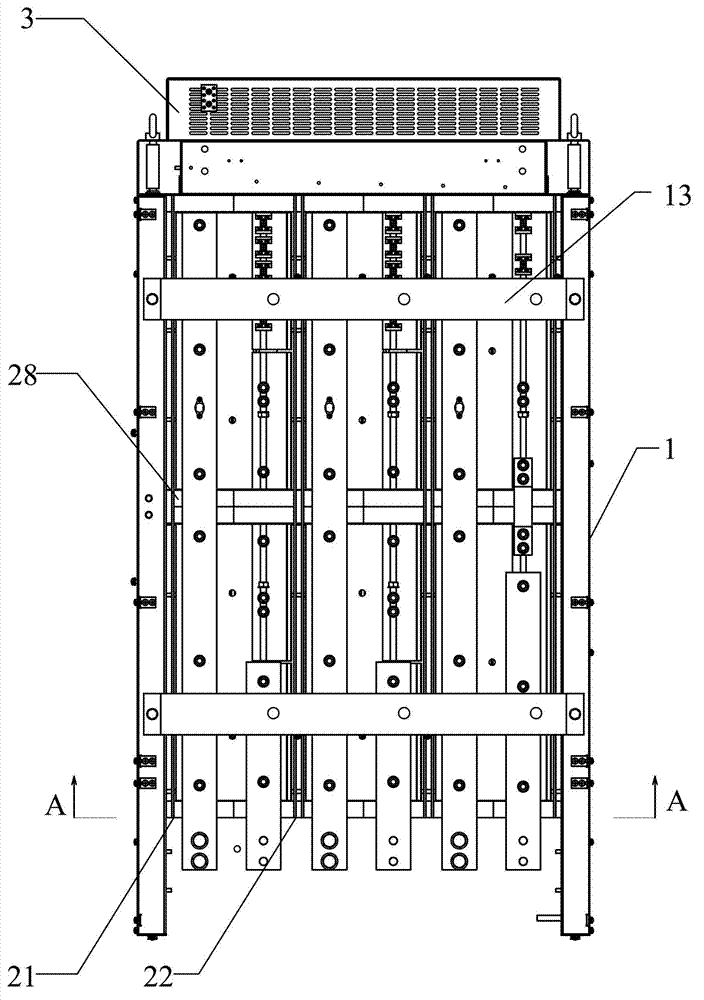

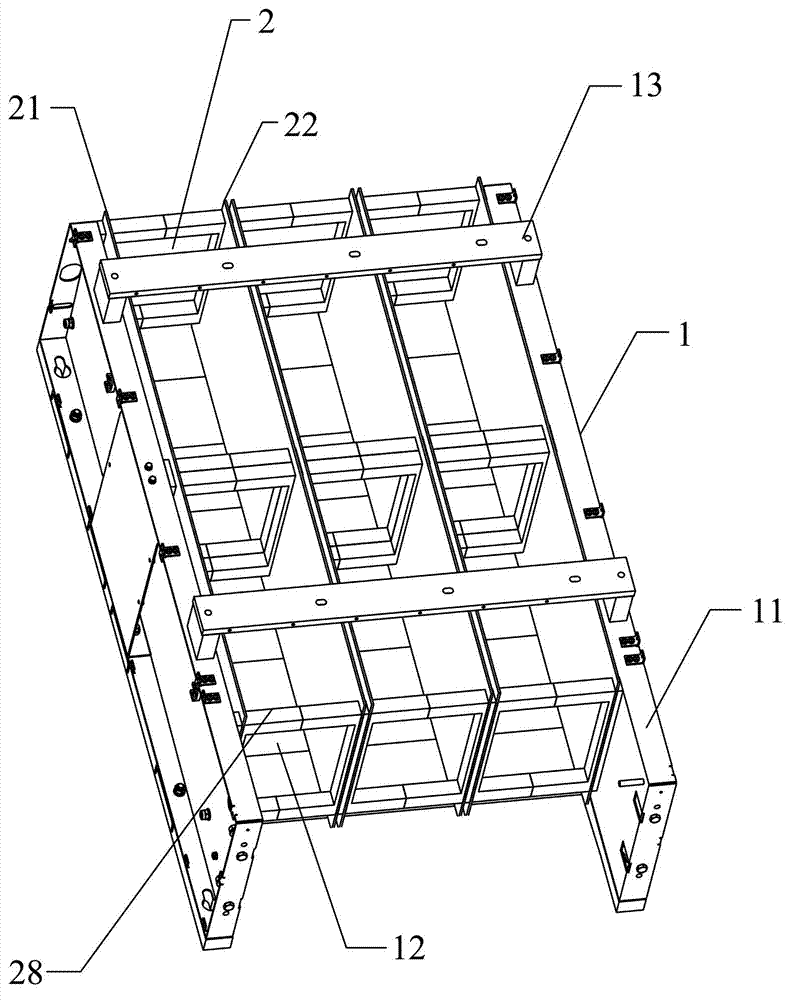

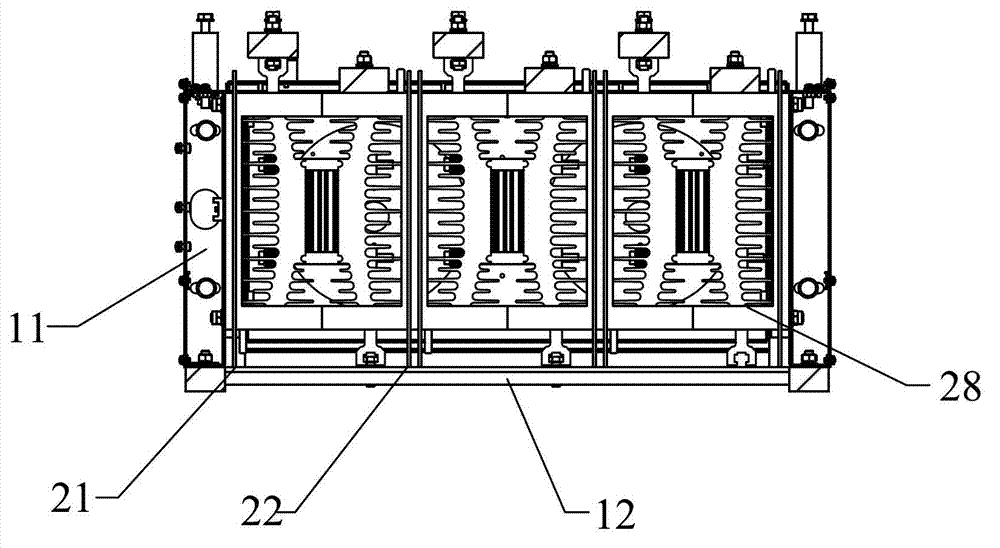

[0025] Such as figure 1 As shown, a heat dissipation device with an independent air duct includes a frame 1 and a fan unit 3, and the frame 1 (such as figure 2 , image 3 shown) includes side walls 11 on both sides and bottom fixing plates 12 connecting the side walls 11 on both sides. In this embodiment, the frame 1 is provided with three sets of Independent air duct 2, said independent air duct 2 includes two sets of heat sink groups composed of heat sink I 23 and heat sink II 24 arranged symmetrically side by side (such as Figure 4 As shown), the heat sink I23 and the heat sink II24 are symmetrically arranged, with a flat silicon press structure, that is, the silicon controlled rectifier material is fixed in the middle of the two heat sinks; the baffles fixed on the left and right sides of the heat sink group The plate I21 and the baffle II22, the baffle I21 and the baffle II22 should be closely attached to the widest position of the two ends of the heat sink group, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com