Thermoacoustically-driven thermally-coupled two-stage pulse tube cooling system

A pulse-tube refrigeration and pulse-tube refrigerator technology, applied in refrigerators, refrigeration and liquefaction, gas cycle refrigerators, etc., can solve problems such as damage and structural distortion, achieve improved pressure ratio, good low-temperature refrigeration performance, and ensure long-term The effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

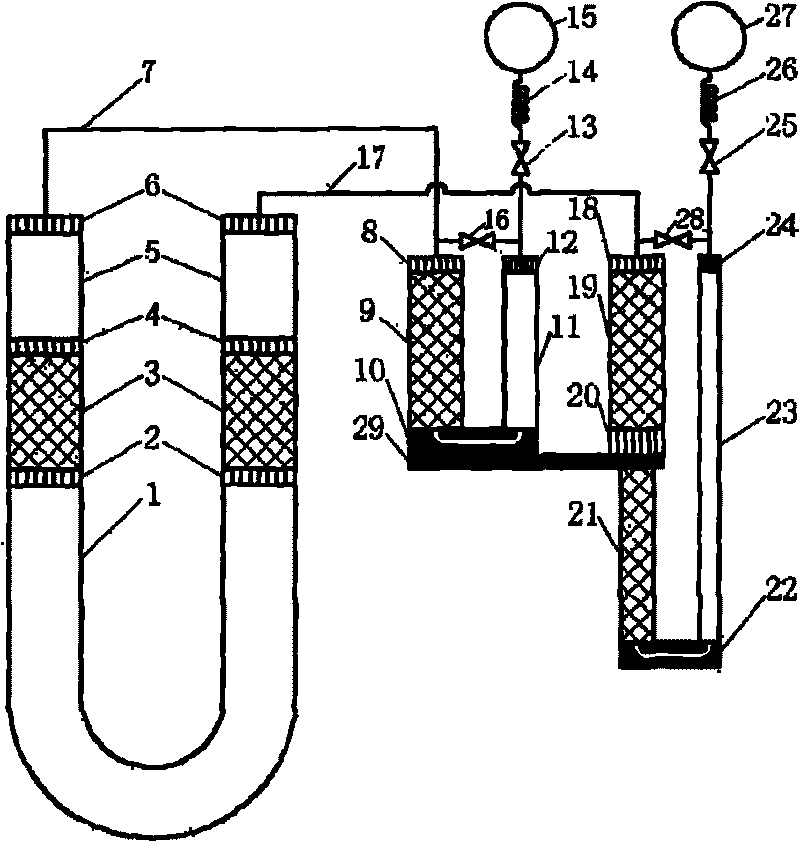

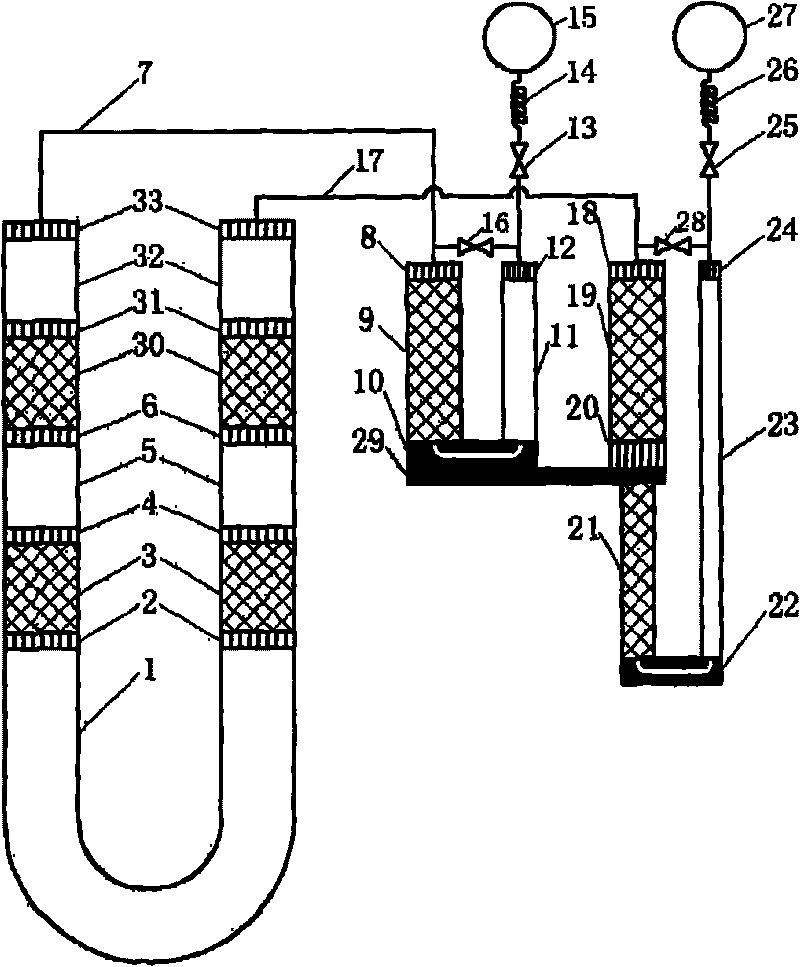

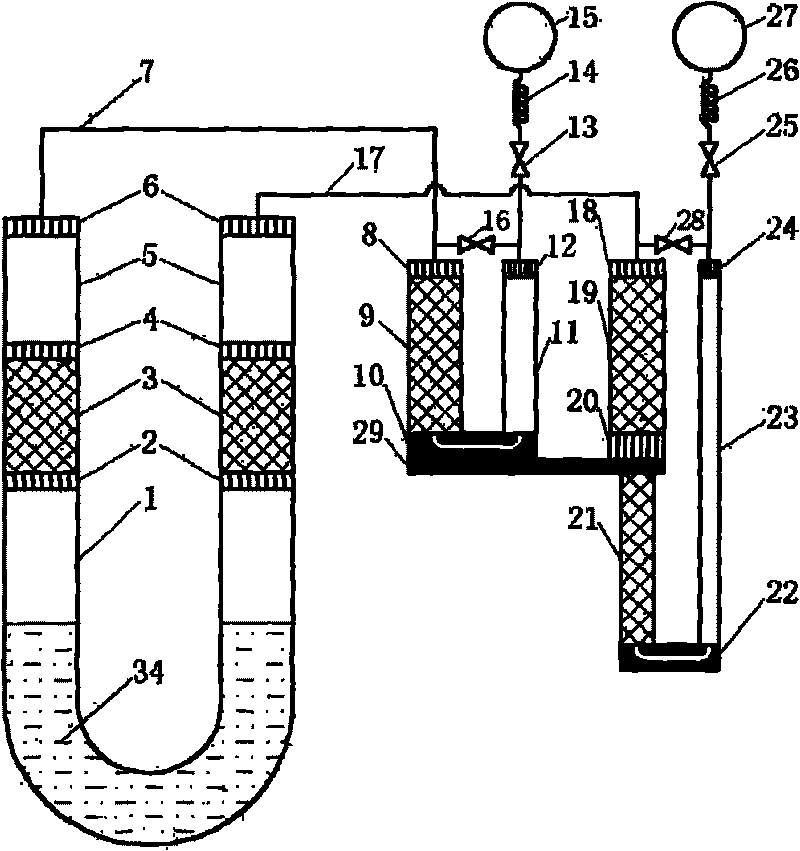

[0017] The invention proposes a novel thermoacoustic-driven heat-coupled two-stage pulse tube refrigeration system aimed at the low-temperature temperature region. In this system, the thermoacoustic engine uses a U-shaped resonant tube to connect two linearly arranged thermoacoustic cores, and the pulse tube refrigerator is a thermally coupled two-stage pulse tube refrigerator with independent gas paths. The core drives the first and second stages of the pulse tube refrigerator, respectively. The two stages of the pulse tube refrigerator are respectively connected at the pressure antinode positions at both ends of the thermoacoustic engine to utilize the maximum pressure ratio of the thermoacoustic engine. At the same time, the non-loop structure avoids the influence of Gedeon DC on the efficiency and the possible thermal expansion. Related structural damage problems. At the same time, in this system, the sound work generated by the thermoacoustic plate stack flows out from i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com