Fluid machine

a technology of fluid machine and split-pipe, which is applied in the direction of positive displacement liquid engine, positive displacement pump components, piston pumps, etc., can solve the problems of affecting the service life of the coil, the efficiency of the linear motor with the split-pipe located in between, and the efficiency of the linear motor with the split-pipe located outsid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

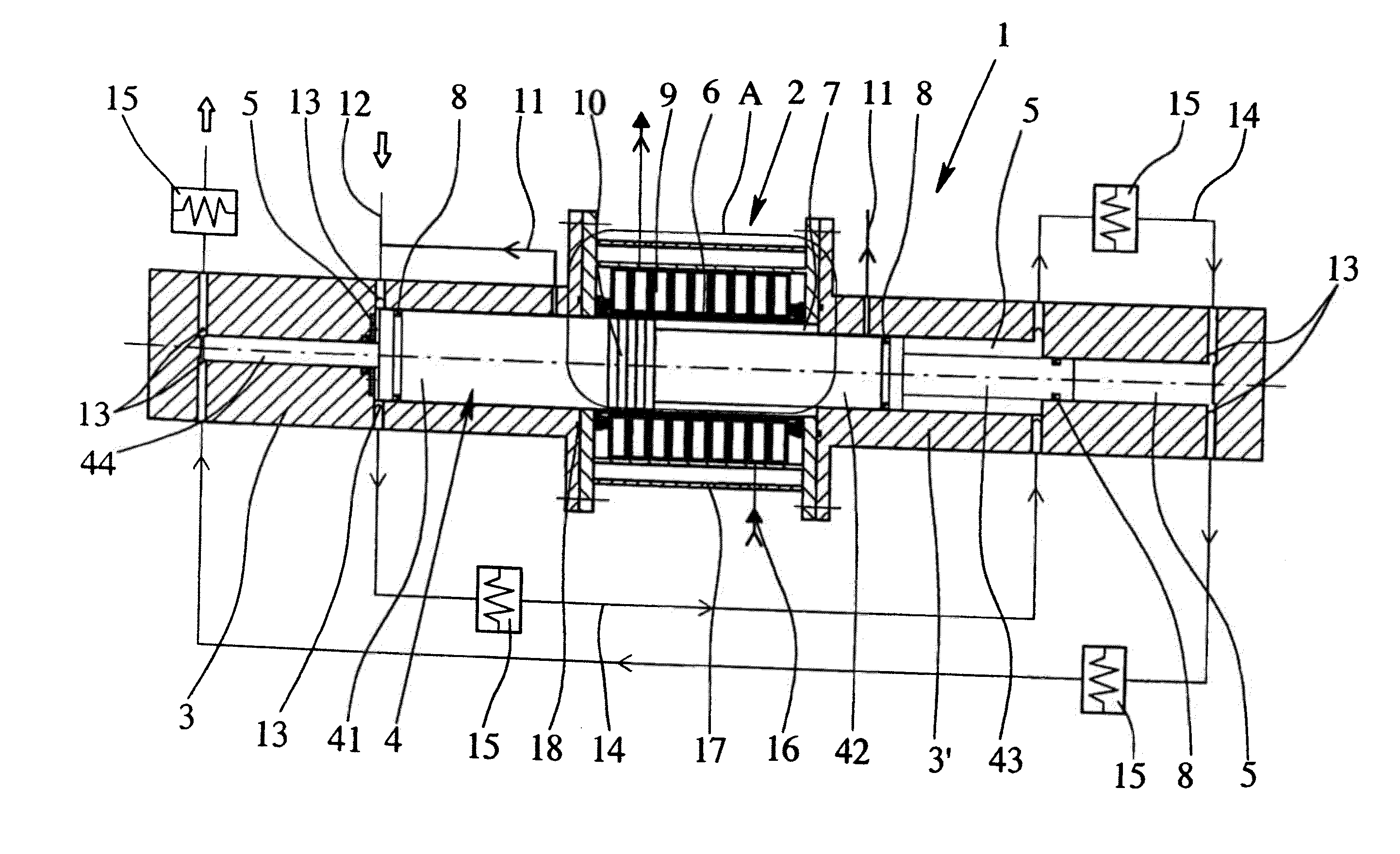

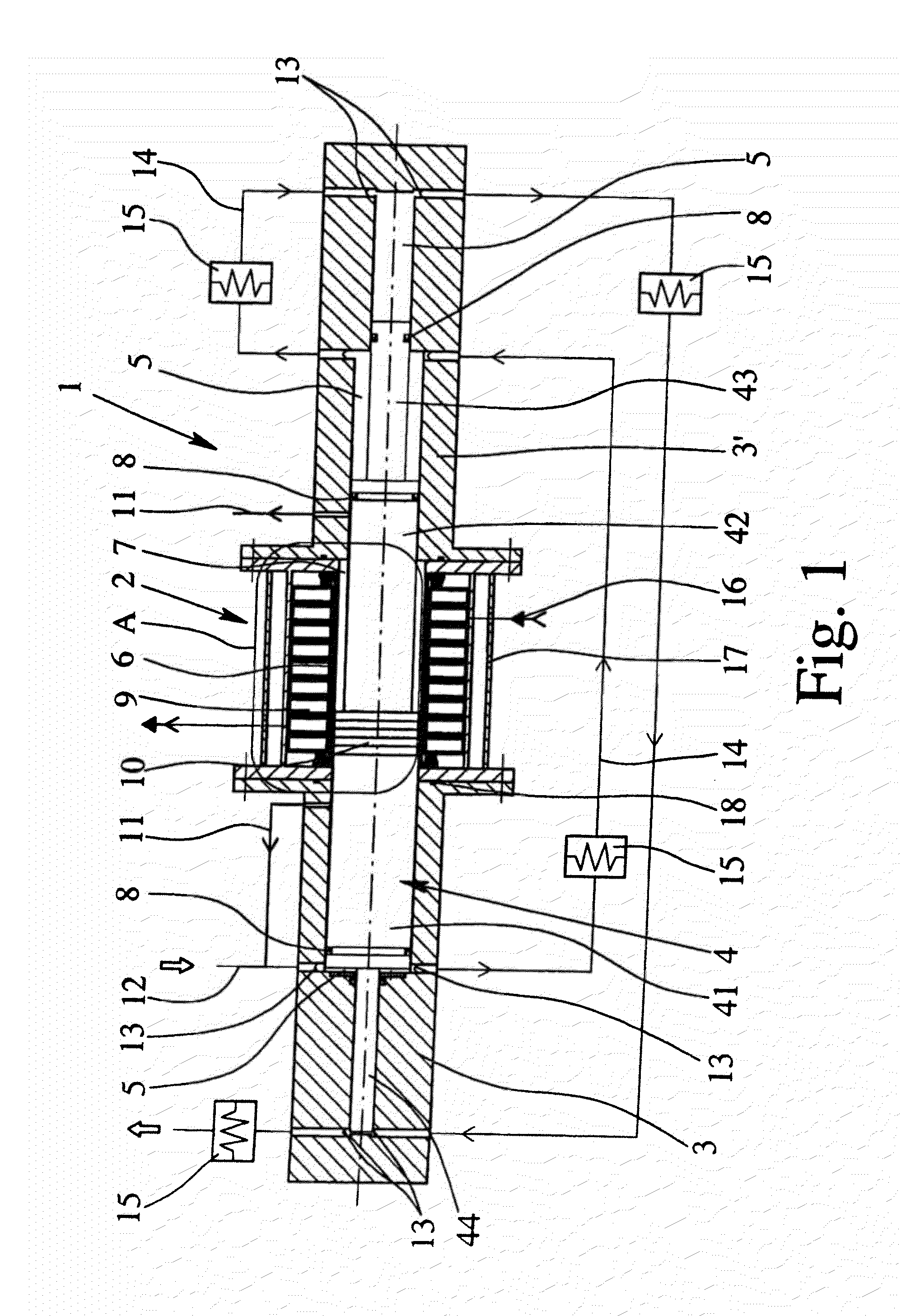

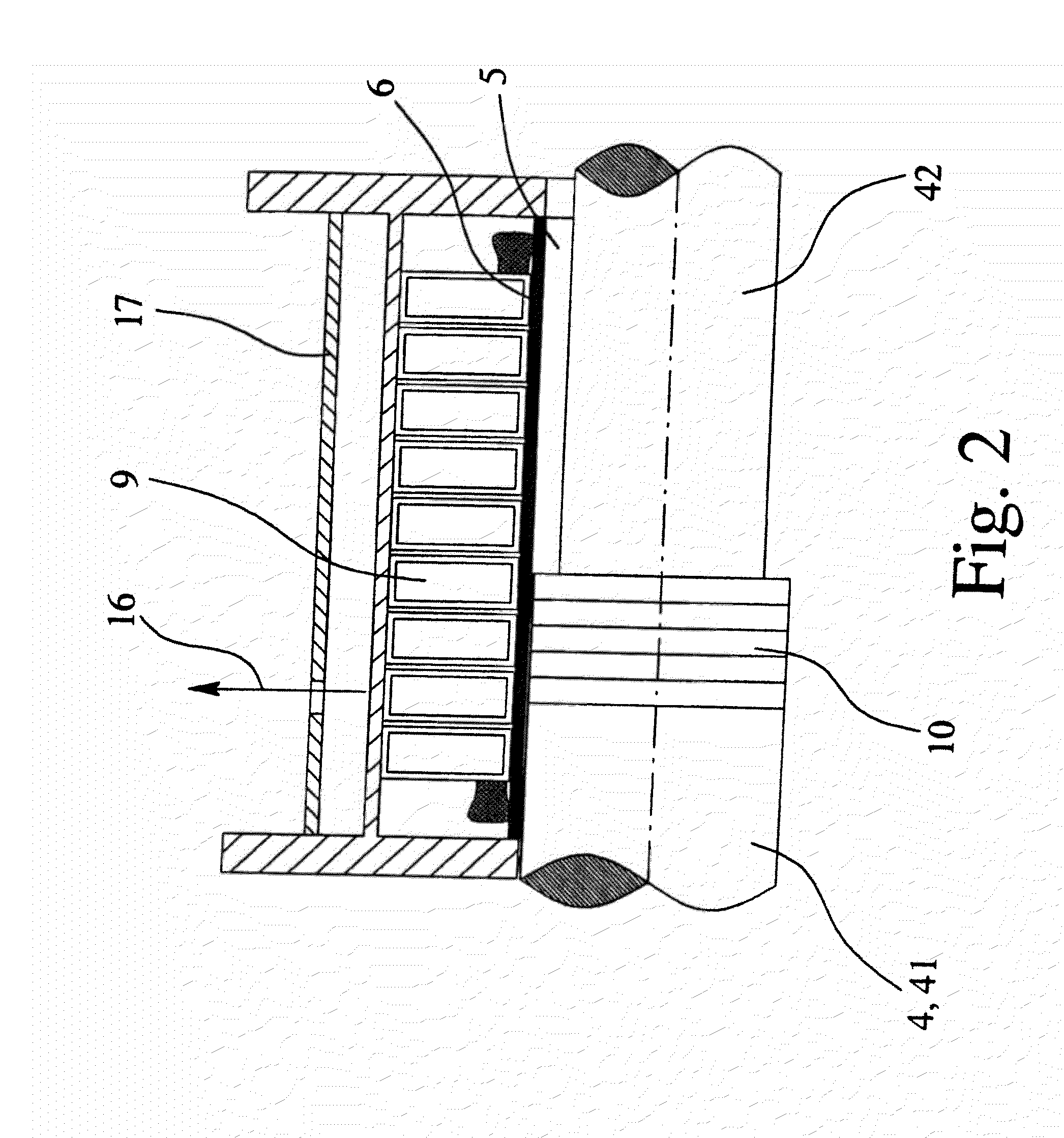

[0032]FIGS. 1, 3, 5 and 6 show four different embodiments of a fluid machine 1 in accordance with the invention, the figures being solely simplified representations, so that only the components important to the invention are shown. The fluid machines 1 shown in the figures are used for compressing gases, especially hydrogen, to a high pressure of 500 bar, for example. These fluid machines 1 can therefore advantageously be used especially for outfitting hydrogen filling stations.

[0033]The fluid machines 1 shown in FIGS. 1, 3, and 5 each have a linear motor 2 for driving a solid piston 4 which is movably located in a cylinder 3. By using the linear motor 2 as a drive, a translational driving force is applied to the solid piston 4 so that the solid piston 4 can move back and forth axially within the cylinder 3, 3′. Within the cylinder 3 is at least one compression space 5 for the gas to be compressed, the size of the compression space changing depending on the position of the solid pis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com