Foam flooding physical simulation device and foam flooding physical simulation method

A technology of physical simulation and foam flooding, which is used in earth-moving drilling, fluid production, wellbore/well components, etc. It can solve the problem of inability to realize real-time mixing of displacement medium, inability to ensure liquid uniformity, and poor back pressure control accuracy. problems, to achieve the effect of high control accuracy and automation, ensuring continuity and stability, and smooth operation of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

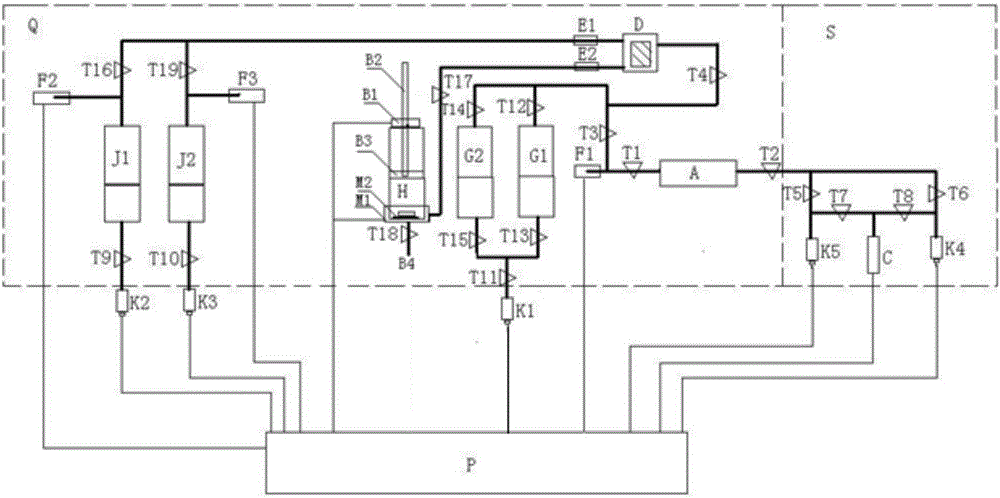

[0050] The foam flooding physical simulation device and method of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0051] like figure 1 As shown, the embodiment of the foam flooding physical simulation device of the present invention is a kind of foam flooding physical simulation device used in the laboratory environment (the thick line represents the physical pipeline connection, and the thin line represents the electrical connection), including The model part of the reservoir, the injection part of injecting crude oil or high-pressure displacement medium (foam or water) into the model part, and the effluent collection part of collecting the effluent of the model part.

[0052] The model part in this embodiment is the core holder A, which belongs to the prior art, and it is used to make core samples of different oil levels and as a container for placing samples. It has an inlet connected to the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com