Pressure-measuring fiber grating process and device

A fiber grating and measurement method technology, which is applied in the measurement of the change force of the optical properties of the material when it is stressed, the use of diffractive elements to generate spectrum, spectrum generation and other directions, can solve the problem of poor long-term stability, large volume and slow response speed. and other problems, to achieve the effect of large range and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

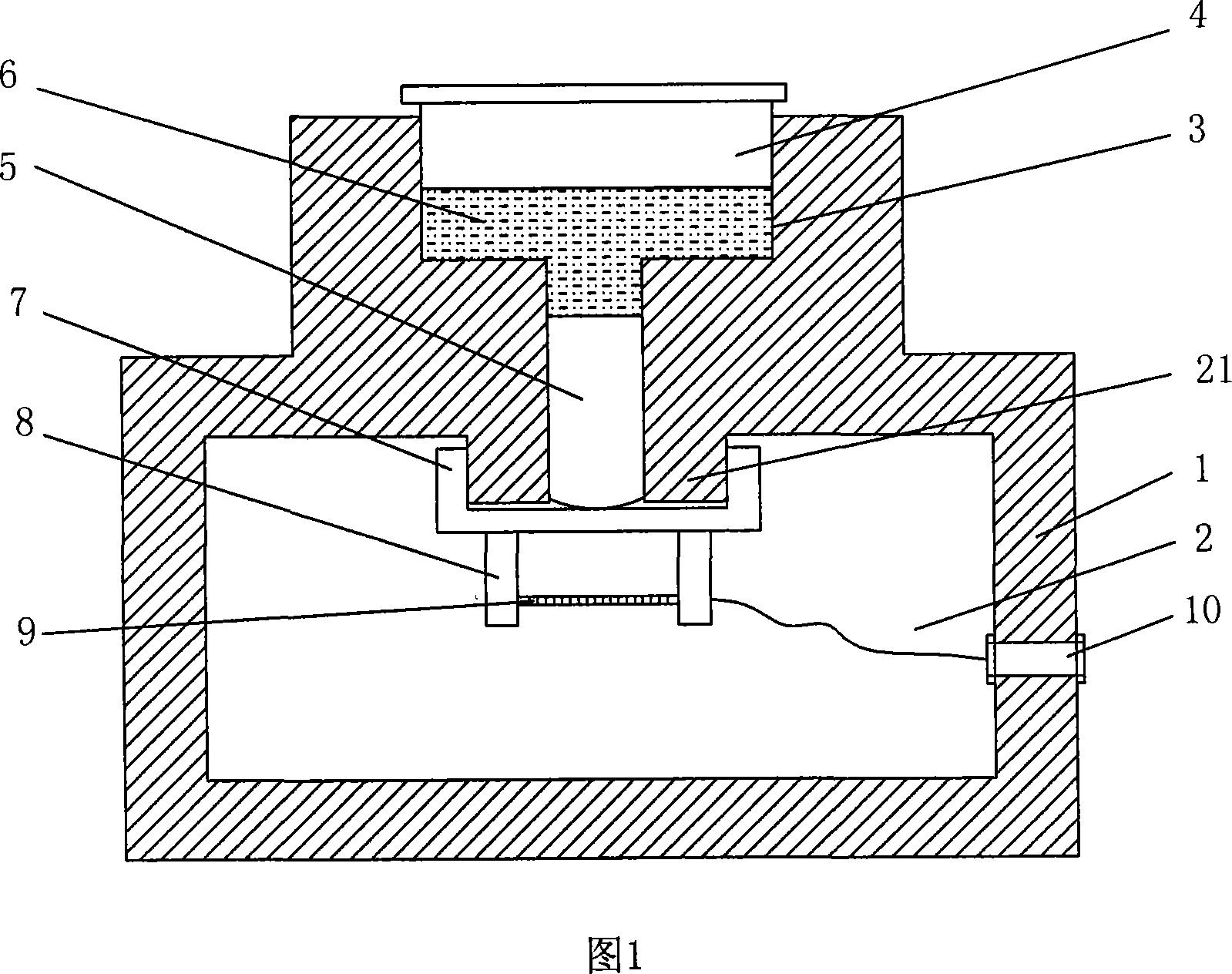

[0019] The present invention will be described in further detail below in conjunction with accompanying drawing, as shown in Figure 1, make a kind of piston-liquid-piston mechanical structure of fixed fiber grating sensing part, this mechanical structure comprises base 1, has cavity in base 1 Chamber 2, the upper part of the base 1 is provided with a stepped hole 3 communicating with the chamber 2, an upper piston 4 and a lower piston 5 are arranged in the stepped hole 3, the cross-sectional area of the upper piston 4 is greater than that of the lower piston 5, The upper piston 4 and the lower piston 5 are filled with hydraulic oil 6, the lower end of the lower piston 5 is spherical, the top surface of the chamber 2 is centered on the central axis of the stepped hole 3, and protrudes downward to form a boss 21, the boss 21 is sleeved with a cylindrical elastic membrane 7, and the lower end of the lower piston 5 can be in contact with the elastic mold 7; the optical fiber grat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com