System and method to eliminate a hard rub and optimize a purge flow in a gas turbine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

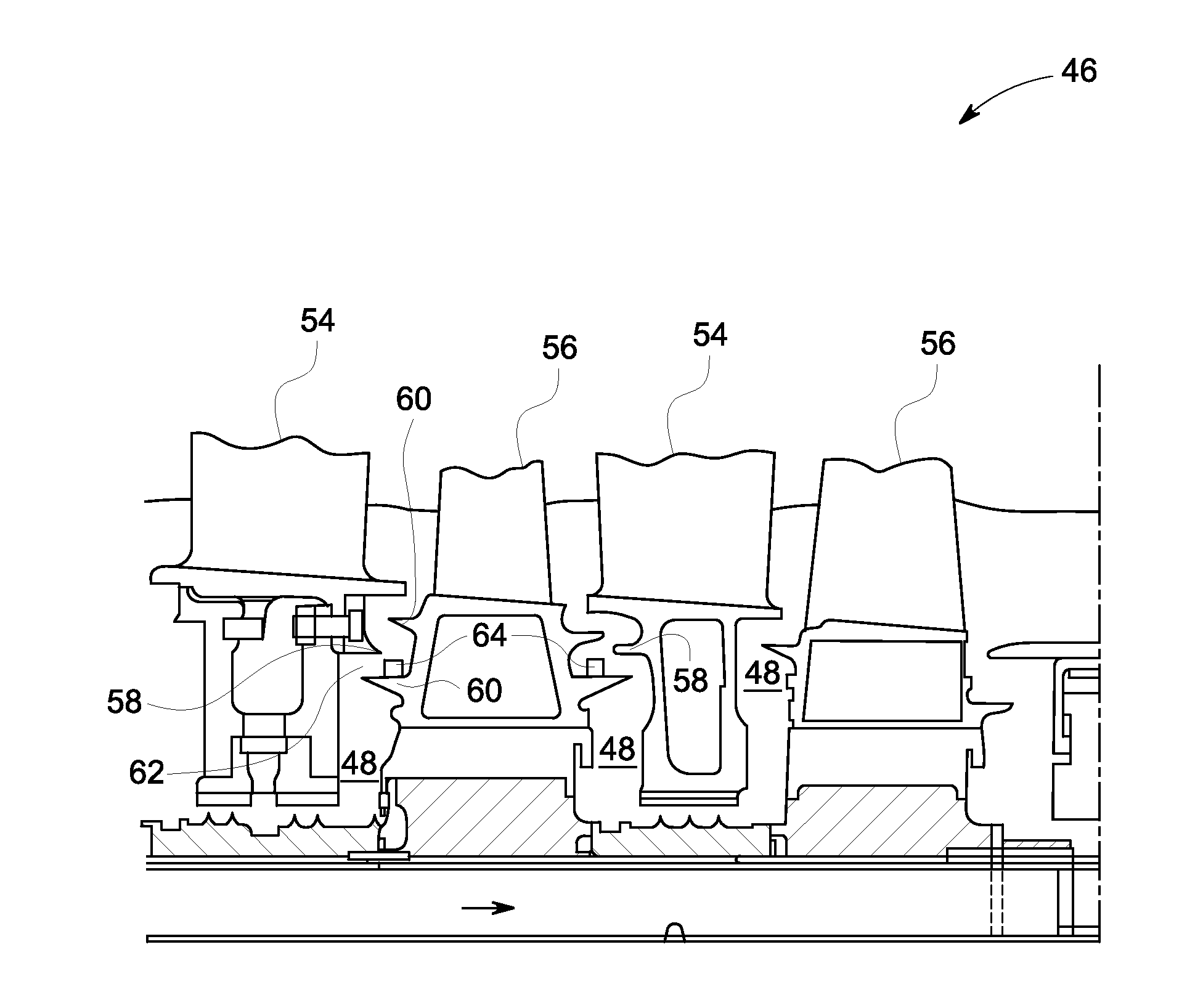

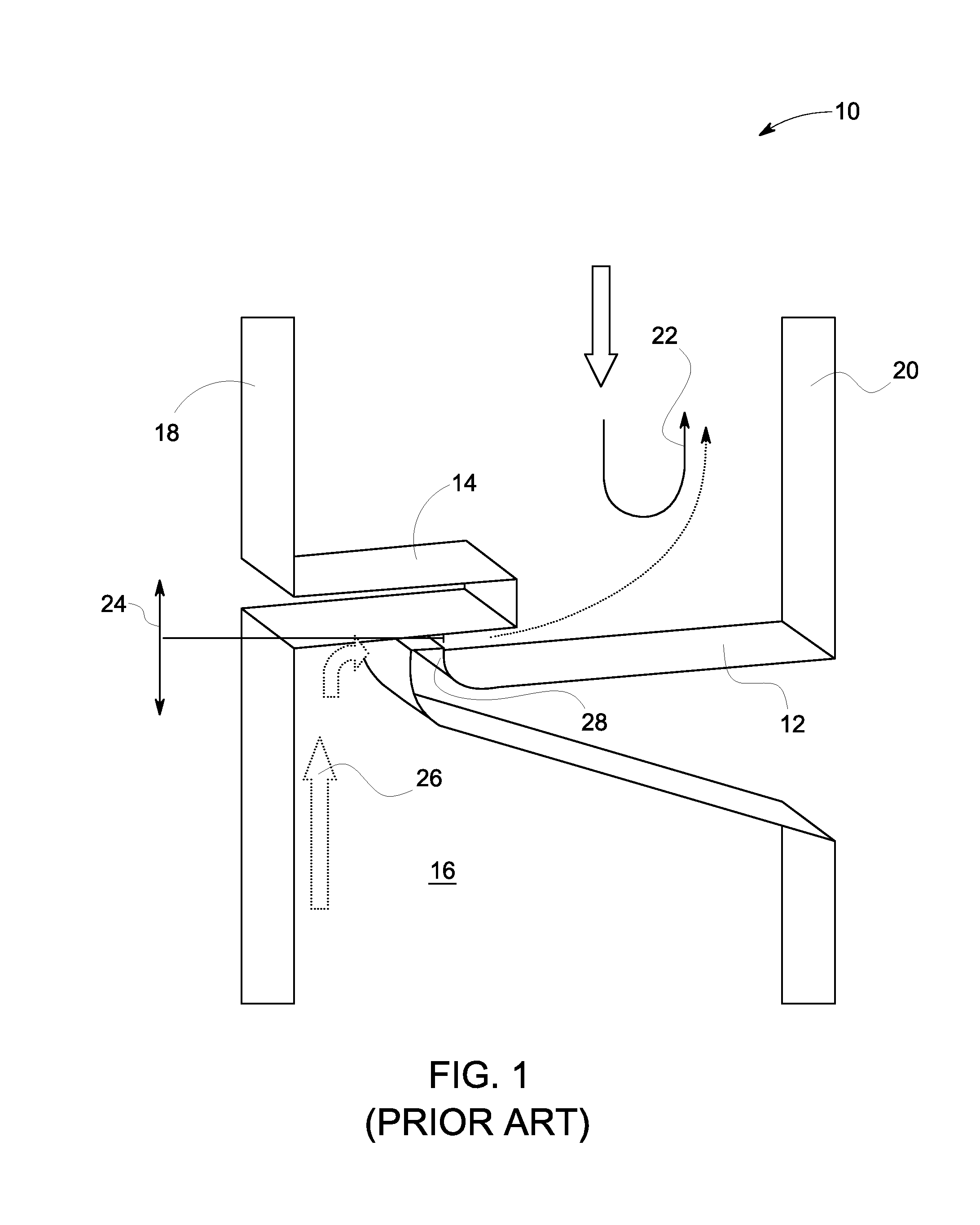

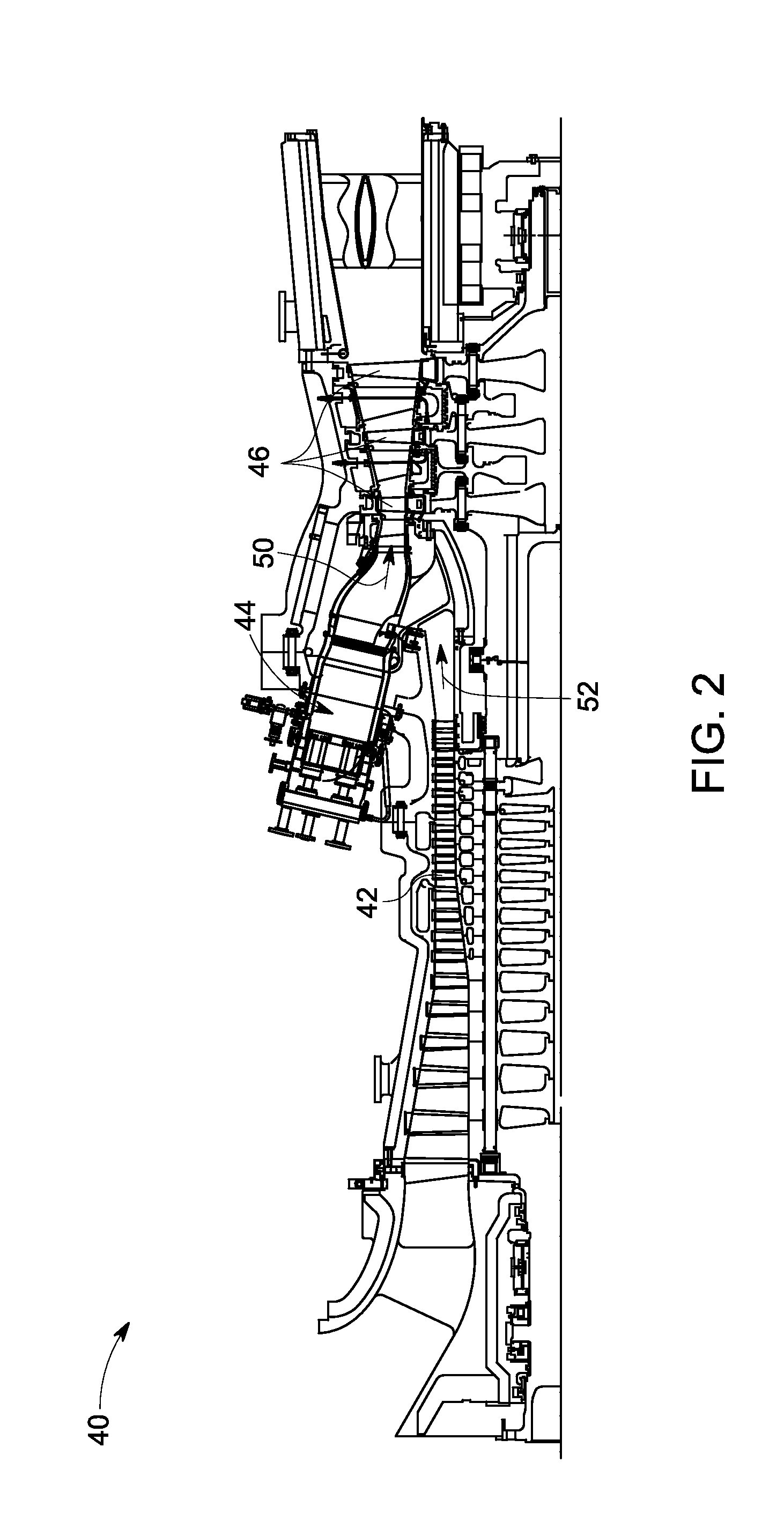

[0017]As discussed in detail below, embodiments of the present invention include a system and method to eliminate a hard rub and optimize a purge flow in a gas turbine. In one embodiment, the system includes an angel wing without a tip that eliminates the hard rub between the angel wing and a discourager. As referred to herein, the term ‘hard rub’ is defined as a rub during startup of the turbine between metal components of the angel wing tip and the discourager. Furthermore, a fan blade is disposed on the angel wing that generates a recirculation zone of the purge flow to reduce a volume of successive purge flows entering a wheel space. As used herein, the term ‘purge flow’ is defined as a gas flow entering the wheel space from a clearance area to prevent overheating and to maintain an acceptable temperature in the wheel space. As referred to herein, the ‘clearance area’ is defined as a gap between the discourager and the angel wing. In another embodiment, the angel wing tip is ret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com