Vacuum preservation device, refrigerator and control method of vacuum preservation device

A technology of vacuum preservation and control method, which is used in packaging under vacuum/special atmosphere, household refrigeration devices, transportation and packaging, etc., can solve the problems of difficult control of stability, high cost, high failure rate, and avoid the environment of food preservation. Effects of deterioration, prolonged storage time, and reduced manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

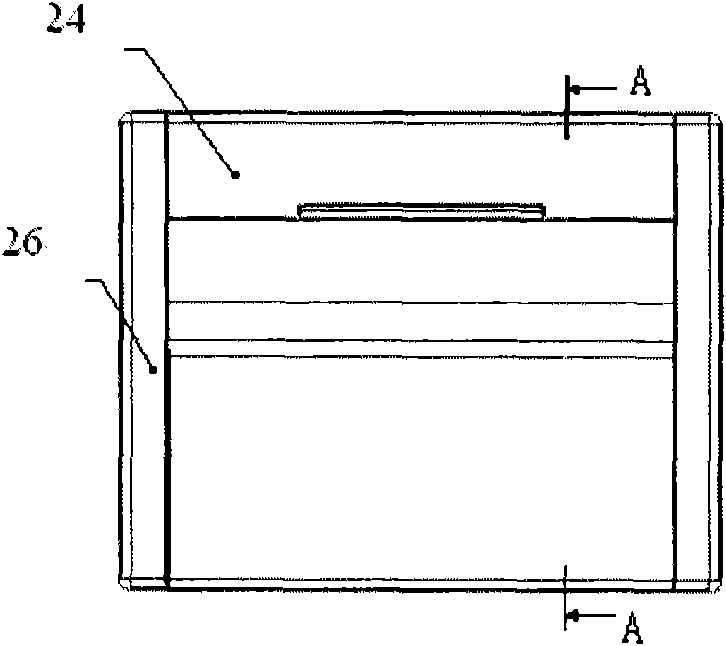

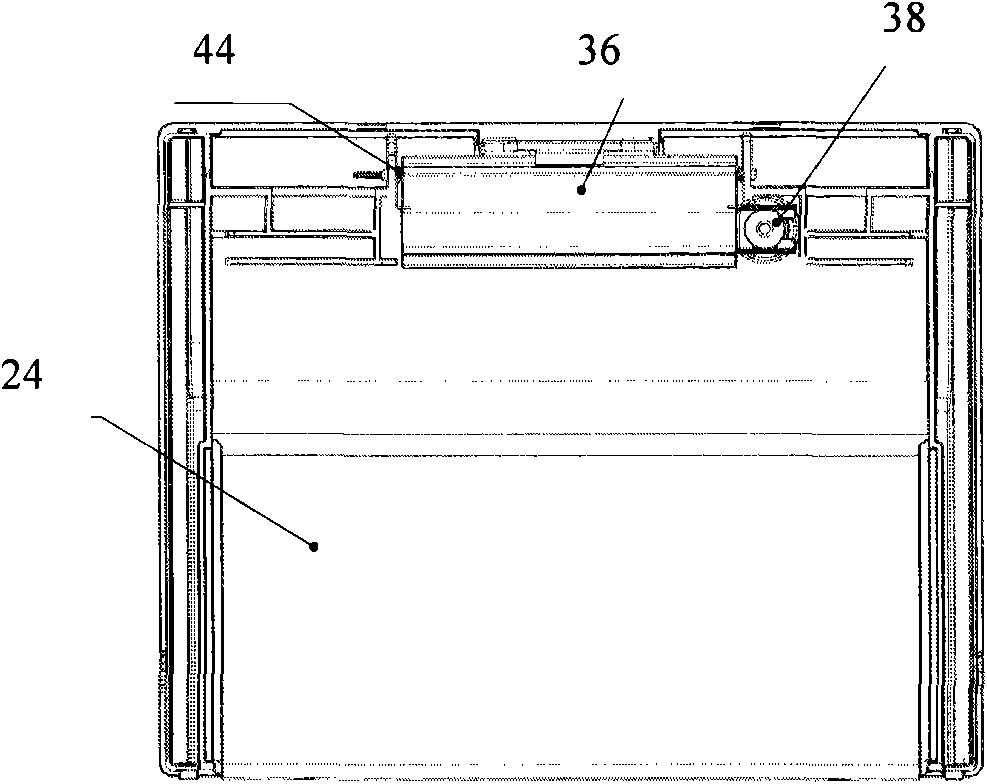

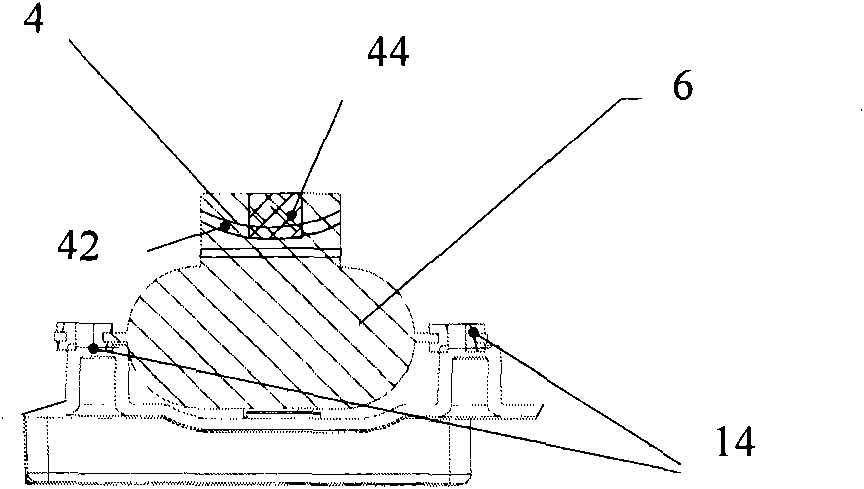

[0024] See attached Figure 1-5 , the vacuum fresh-keeping device of the present invention comprises a vacuum fresh-keeping container 2, a vacuum pump 6, and a pressure switch 4, wherein the pressure switch 4 is fixed on the vacuum pump 6, and the pressure switch 4 switches the vacuum pump 6 reciprocatingly in response to pressure changes in the vacuum fresh-keeping container 2 to correspondingly Make the vacuum pump 6 vacuumize the vacuum preservation container 2 in a continuous cycle. Thus, a low-oxygen vacuum zone in which the pressure is continuously maintained within a predetermined pressure range is provided in the vacuum preservation container 2 .

[0025] Specifically, see figure 1 The vacuum fresh-keeping device of the present invention shown, wherein, pressure switch 4 is fixed on the top of vacuum pump 6, and the air inlet of vacuum pump 6 is communicated with vacuum fresh-keeping container 2 through rubber hose 62, and the air outlet 64 of vacuum pump 6 is directl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com