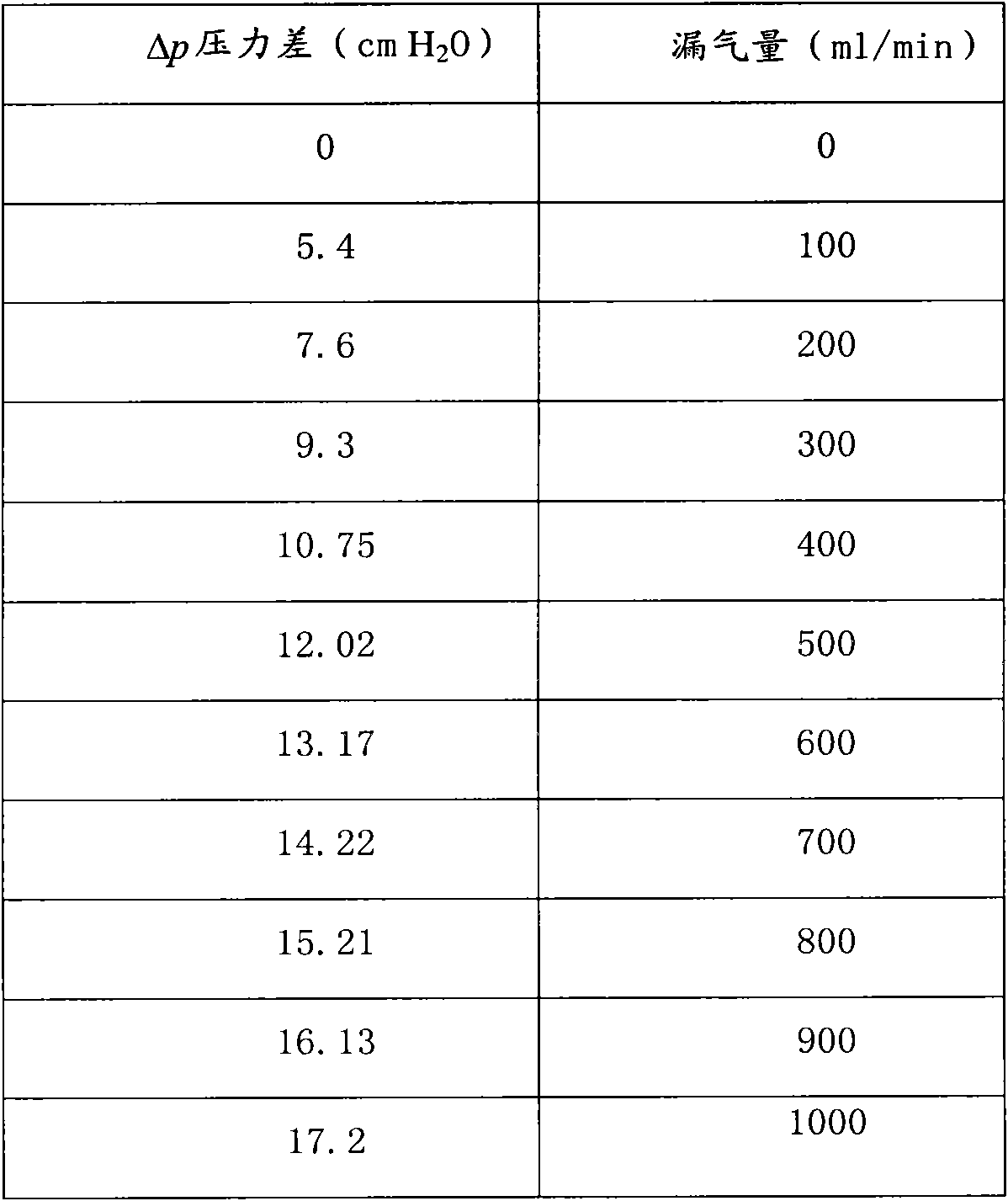

Method for leak detection of anesthesia machine system

A leak detection, anesthesia machine technology, applied in the direction of measuring the acceleration and deceleration rate of the fluid, using liquid/vacuum for liquid tightness measurement, respirator, etc. Quantity and other issues, to achieve the effect of accurate detection methods and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

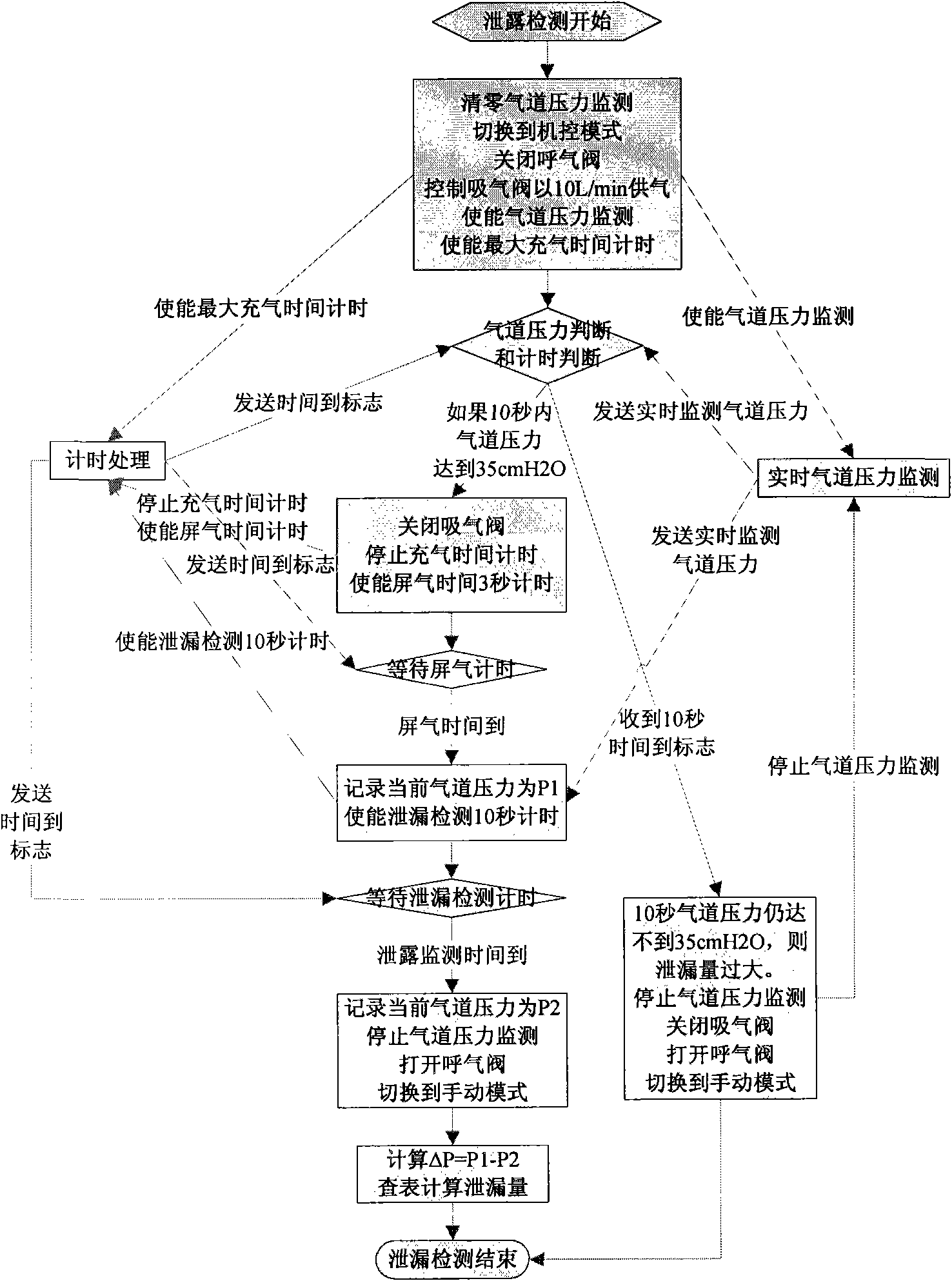

[0020] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0021] Such as figure 2 As shown, the method includes the following steps:

[0022] (1) Clear the airway pressure gauge, switch the anesthesia machine to the machine control mode, close the inhalation valve and exhalation valve, block the air outlet (patient end interface) of the anesthesia machine system, and make the anesthesia machine system a closed cavity.

[0023] (2) Control the inspiratory valve to inflate the anesthesia machine system at a flow rate of 10 L / min, and at the same time turn on the airway pressure sensor inside the anesthesia machine system, and monitor the internal pressure of the anesthesia machine system in real time with the help of the timing processing unit.

[0024] (3) Within 10 seconds, when the airway pressure sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com