Pure-countercurrent cellular plate-pin heat exchanger and combination thereof

A technology of fin heat exchanger and honeycomb plate, applied in the direction of heat exchanger type, indirect heat exchanger, fixed plate duct assembly, etc. Large flow, increase fan output power, etc., to achieve the effect of light weight, compact structure, and improved heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

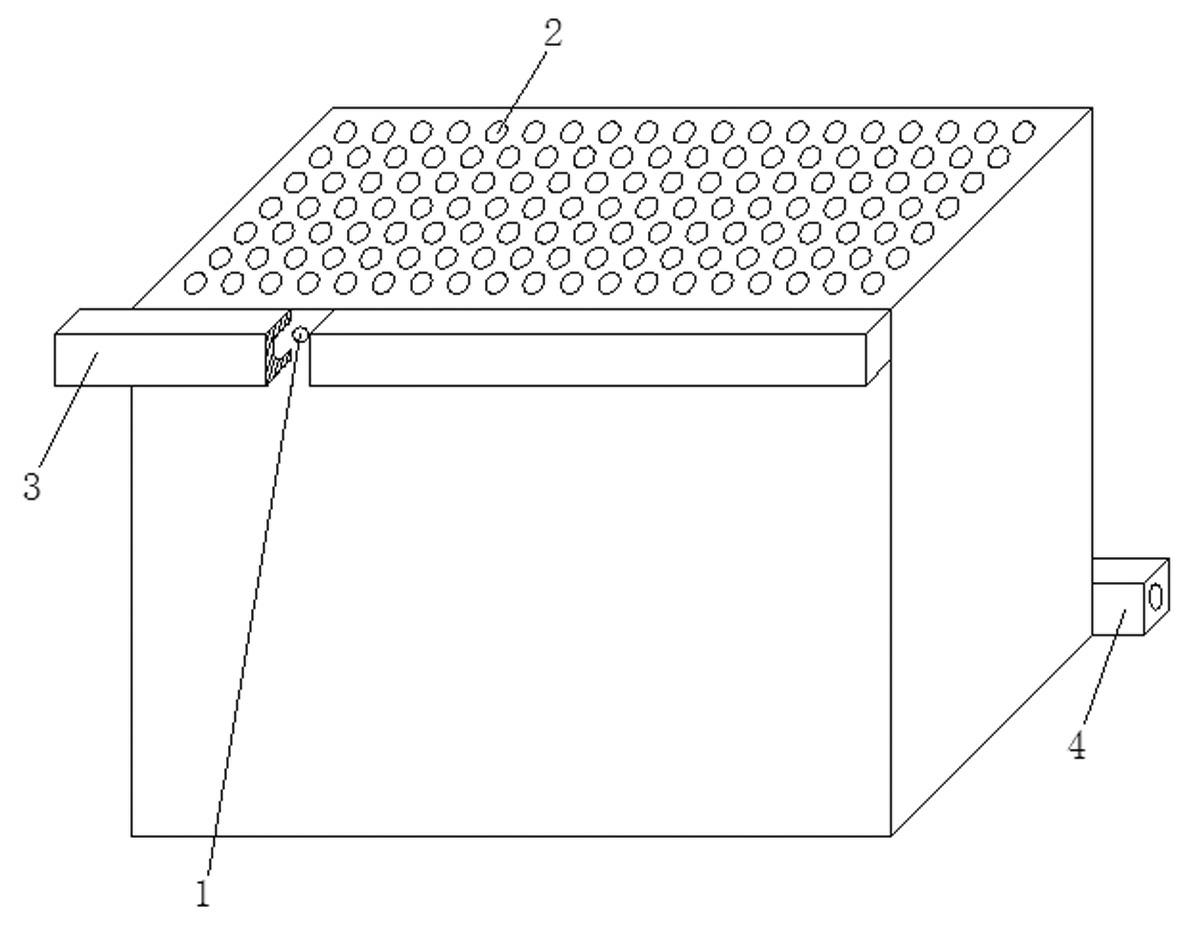

[0022] refer to figure 1 , this embodiment includes a honeycomb heat exchange unit body, the honeycomb heat exchange unit body is provided with a circulation channel A1 and a circulation channel B2 for different fluids, and the circulation channel A1 and the circulation channel B2 are parallel to the surface Alternately arranged, one end of the circulation channel B2 is a fluid inlet, and the other end is a fluid outlet, the circulation channel A1 includes a vertical circulation channel (not shown in the figure) parallel to the circulation channel B2, and one end of the vertical circulation channel The inlet on the upper left side of the heat exchange unit body is connected through a horizontal distribution channel (not shown in the figure), and the other end of the longitudinal flow channel is connected to the right side of the heat exchange unit body through a horizontal confluence channel (not shown in the figure). The outlet at the lower part of the side is connected.

[...

Embodiment 2

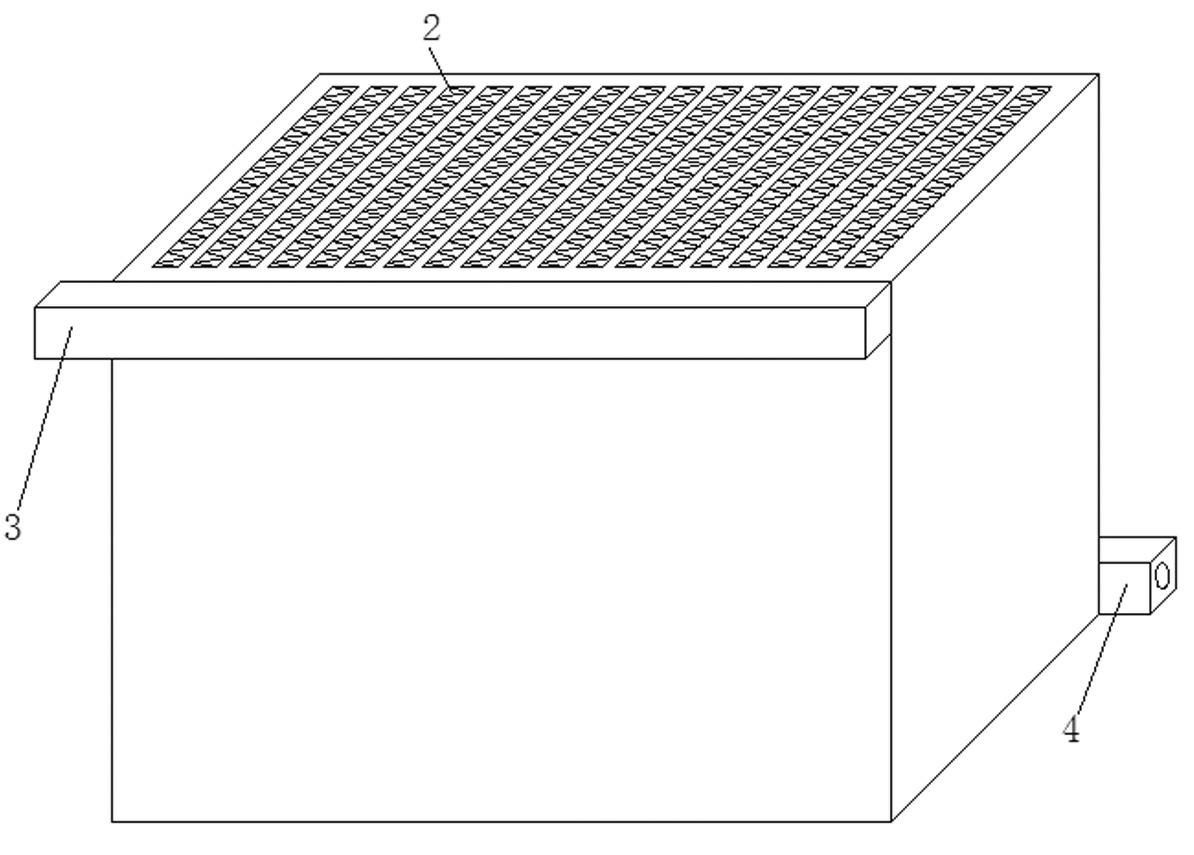

[0028] refer to figure 2 , The difference between this embodiment and Embodiment 1 is: the shape of the honeycomb hole of the circulation channel B2 is triangular. Of course, the shape of the honeycomb holes of the circulation channel B can also be hexagonal, square, rectangular, etc., which will not be repeated here.

Embodiment 3

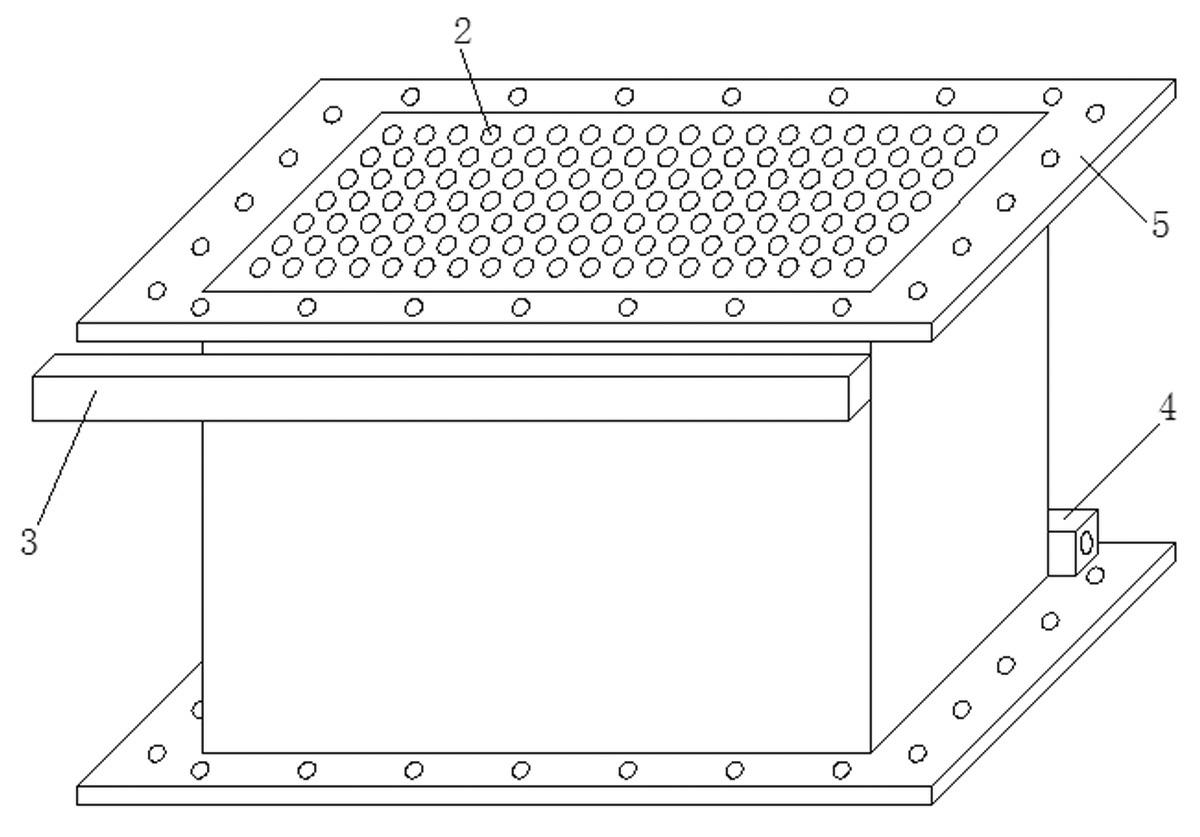

[0030] refer to image 3 , The difference between this embodiment and Embodiment 1 is that: the end faces of the inlets and outlets of the circulation channel B2 are respectively provided with connecting flanges 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com