Refrigerant system with economizer, intercooler and multi-stage compressor

A refrigerant system and refrigerant technology, applied in the direction of compressors, irreversible cycle compressors, refrigerators, etc., can solve the problems of low feasibility of intercoolers, improve the performance of refrigerant systems, improve reliability, and high Effect of refrigerant cooling potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

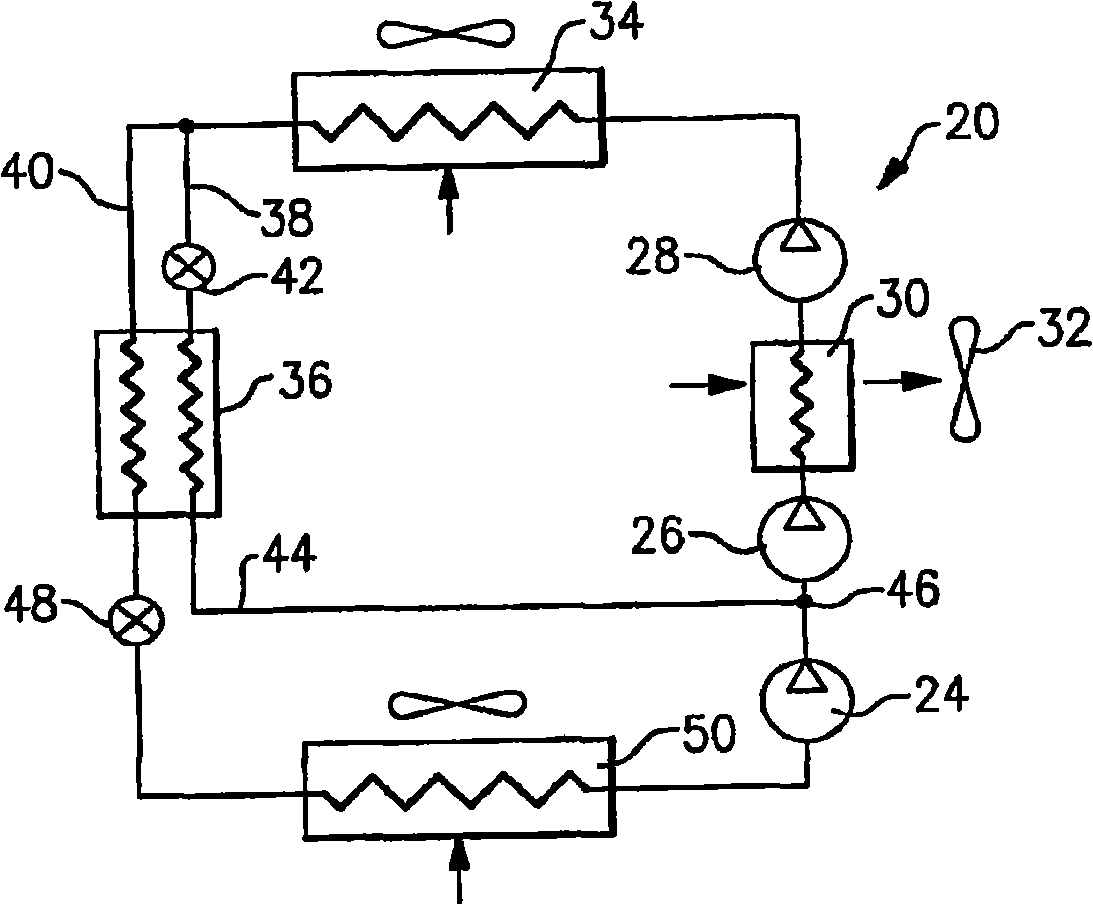

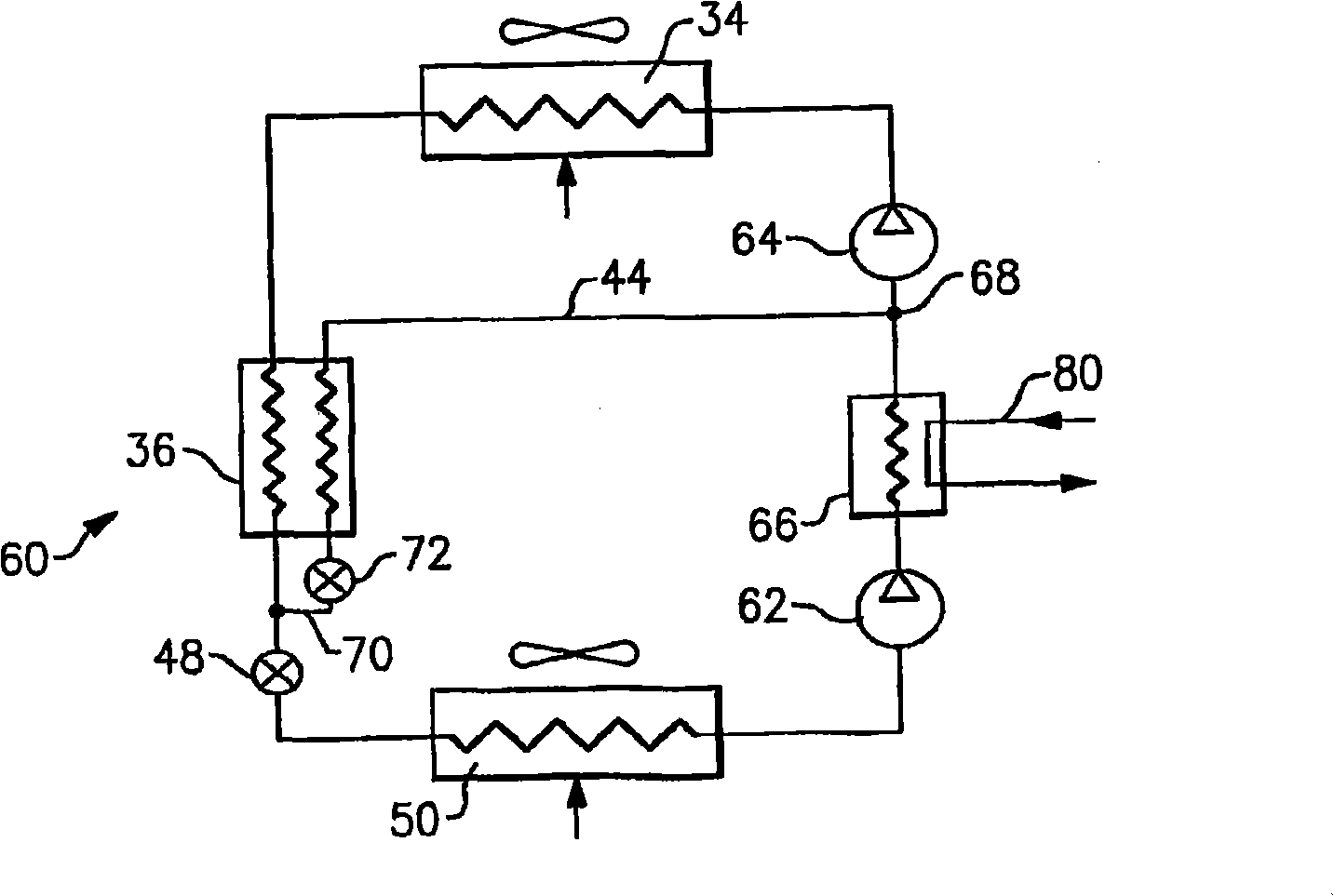

[0017] figure 1 A refrigerant system 20 is illustrated. Three compression stages 24, 26 and 28 are arranged in series in refrigerant system 20 to asymptotically compress the refrigerant from suction pressure to discharge pressure. While multi-stage compressor systems are represented by separate compressor units arranged in series, such as figure 1 shown, but a separate compression member could be used instead of some or all of the compressor unit. Specifically, for example in the case of a three-stage reciprocating compressor, three separate compression members may represent different banks of cylinders connected in series. The refrigerant compressed by the first stage from the suction pressure to the first intermediate pressure is transported from the discharge port of the first stage to the suction port of the second stage. Refrigerant vapor is compressed by the second stage to a second intermediate pressure and conveyed from the discharge of the second stage to the sucti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com