Air-conditioning system using sub-cooler and method for controlling refrigerant flow thereof

A refrigerant flow, air conditioning system technology, applied in subcoolers, refrigerators, refrigeration components, etc., can solve the problems of inability to exert the effect of subcoolers, affect reliability, system hazards, etc., to improve operating efficiency and operation. life, guarantee the use effect, and improve the effect of refrigerant subcooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

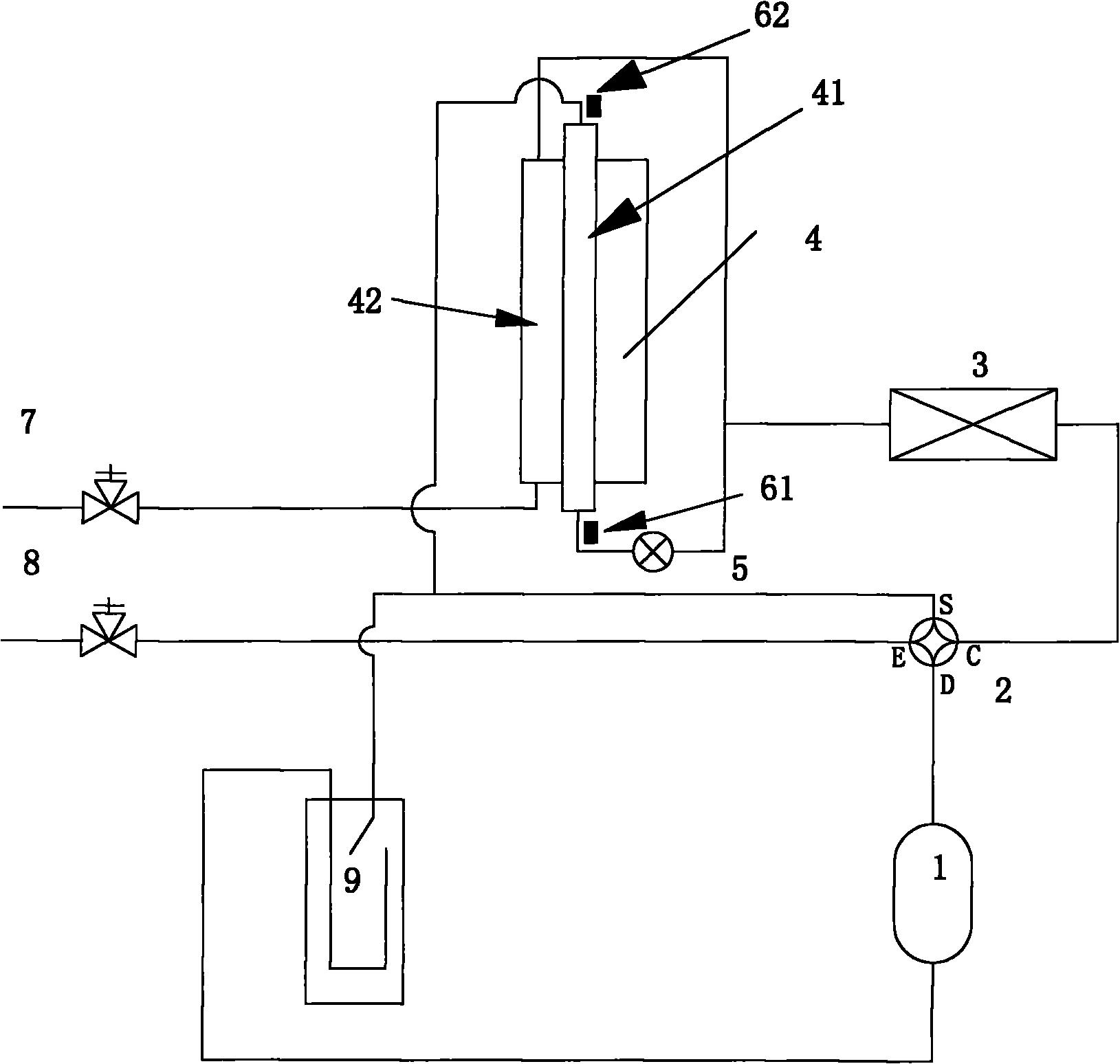

[0032] Such as figure 1 , the first sensor and the second sensor in this embodiment are respectively the first temperature sensor 61 and the second temperature sensor 62, the first temperature sensor 61 is arranged at the inlet end position of the gas pipe 41 of the subcooler, and the second The temperature sensor 62 is located at the outlet end of the gas pipe 41 of the subcooler.

[0033] The refrigerant flow control method in this embodiment is based on the temperature difference control of the gas inlet and gas outlet temperatures on the low-pressure side of the subcooler during the operation of the unit, by controlling the opening of the electronic expansion valve located on the liquid bypass pipeline To realize the control of the refrigerant flow through the low-pressure side of the subcooler; the specific control method is:

[0034] The opening position of the electronic expansion valve is equal to:

[0035] Current opening = original opening + opening change

[0036...

Embodiment 2

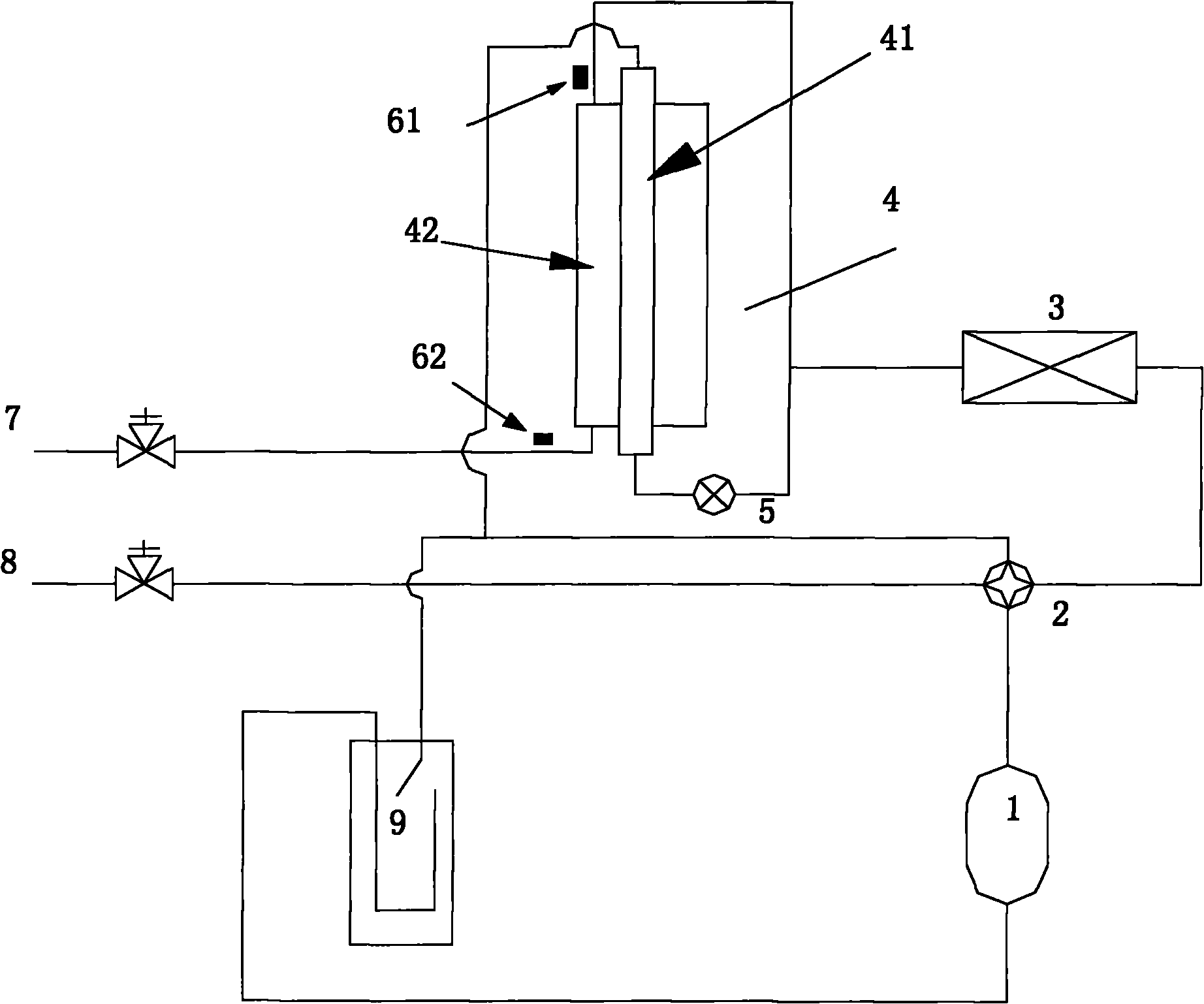

[0042] Such as figure 2 , the first sensor and the second sensor in this embodiment are respectively a first temperature sensor 61 and a second temperature sensor 62, the first temperature sensor 61 is arranged at the inlet end of the liquid pipe 42 of the subcooler, and the first temperature sensor The second temperature sensor 62 is located at the outlet end of the liquid pipe 42 of the subcooler.

[0043] The refrigerant flow control method in this embodiment is based on the temperature difference control of the liquid inlet and liquid outlet temperatures on the high-pressure side of the subcooler during the operation of the unit, by controlling the opening of the electronic expansion valve located on the liquid bypass pipeline To realize the control of the refrigerant flow through the low-pressure side of the subcooler; the specific control method is:

[0044] The temperature T of the refrigerant here is measured in real time by the temperature sensor installed at the in...

Embodiment 3

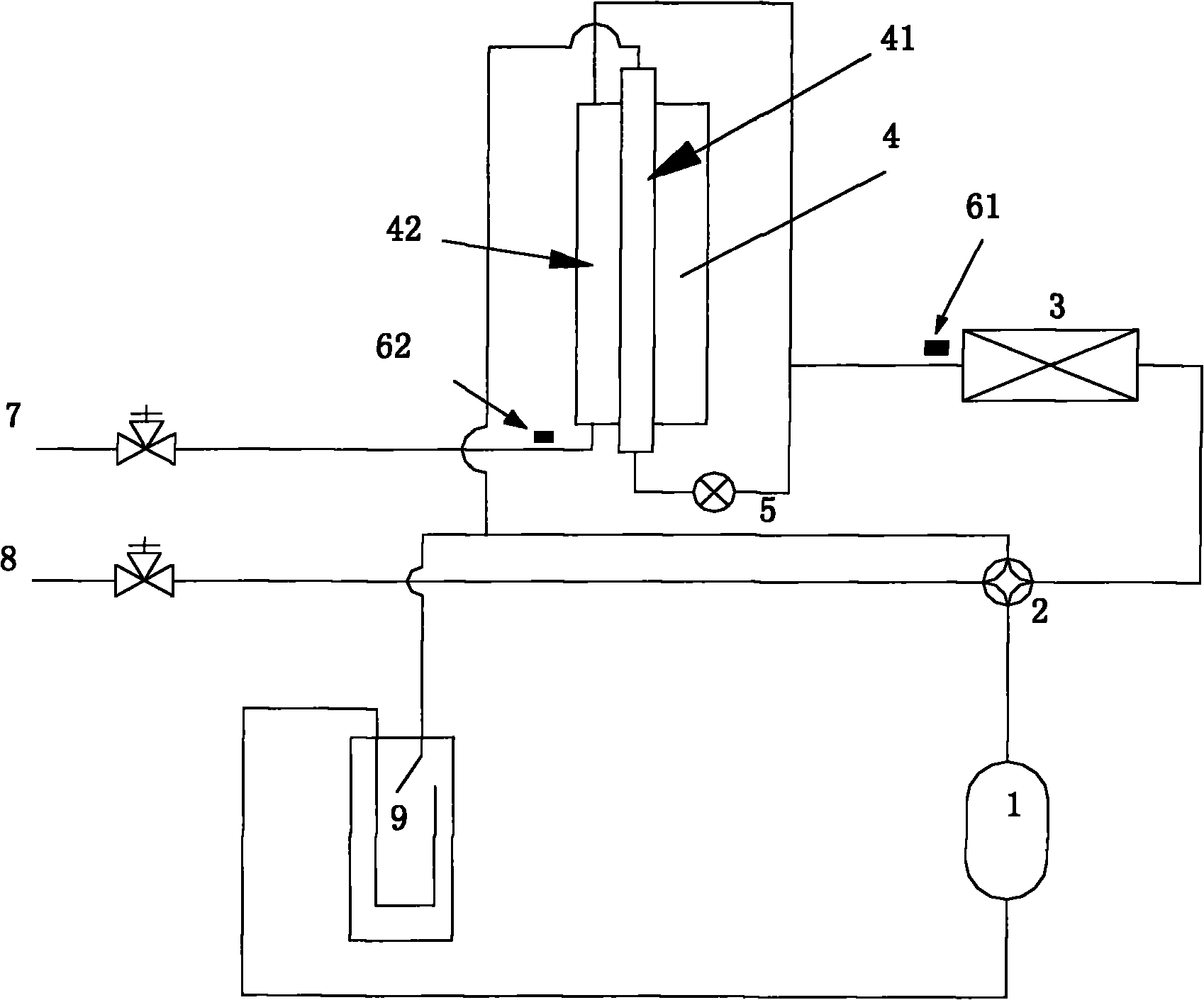

[0052] Such as image 3 , the first sensor and the second sensor in this embodiment are respectively the first temperature sensor 61 and the second temperature sensor 62, the first temperature sensor 61 is set at the second end of the outdoor heat exchanger 3, and the second temperature The sensor 62 is located at the outlet end of the liquid pipe 42 of the subcooler.

[0053] In the control mode of the refrigerant flow in this embodiment, during the operation of the unit,

[0054] During the operation of the unit, based on the temperature difference control of the pipe temperature at the second end of the outdoor heat exchanger and the temperature at the outlet end of the liquid pipe on the high pressure side of the subcooler, it is realized by controlling the opening of the electronic expansion valve located on the liquid bypass pipe Control the refrigerant flow through the low-pressure side of the subcooler; the specific control method is:

[0055] The opening position of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com