Braking system for fan blade rotating shaft of wind generating set

A technology of wind turbines and braking systems, which is applied in the control of wind turbines, wind turbines, and wind power generation. It can solve problems such as fire hazards, shutdown maintenance hazards, and brakes that cannot be manually braked, achieving the effect of simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings.

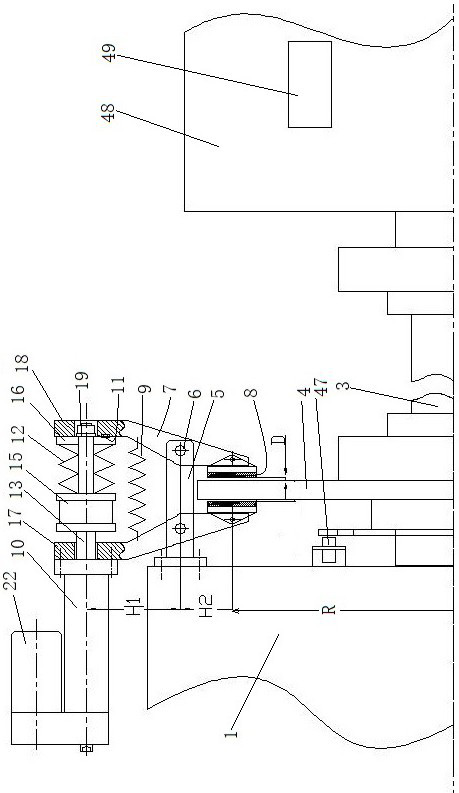

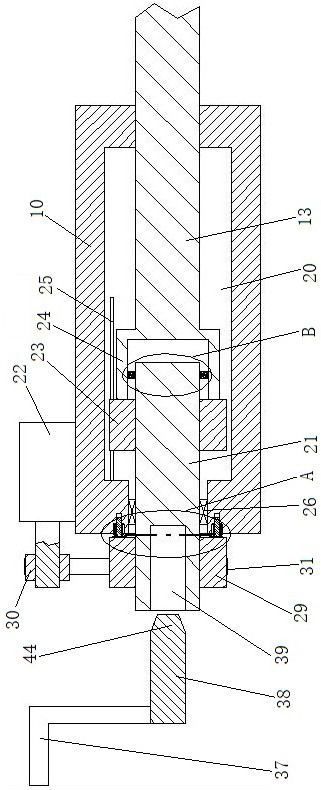

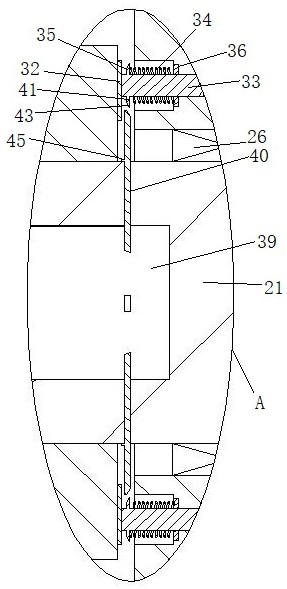

[0027] see Figure 1 to Figure 7 , a wind turbine blade rotating shaft braking system, including a gearbox 1, a rotating blade rotating shaft 3 connected to the gearbox, a brake disc 4 arranged on the fan rotating shaft, a control unit, and a brake disc for detecting the rotational speed A rotational speed sensor 47, a power sensor 49 for detecting the output power of the generator 48, and several brakes 50 distributed along the circumferential direction of the brake disc.

[0028] The brake includes a support 5 , a driving force detection unit and two scissor arms 7 whose middle parts are hinged on the support through pin shafts 6 . Two scissor arms are symmetrically distributed on both axial sides of the brake disc. One end of the scissor arm is provided with a friction plate 8 for cooperating with the brake disc, and the other end is connected together by an ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com