Filling nozzle of liquid filling machine

A filling machine and filling nozzle technology, applied in packaging and other directions, can solve the problems of dirty packaging, difficult packaging, liquid splashing, etc., and achieve the effect of avoiding dripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

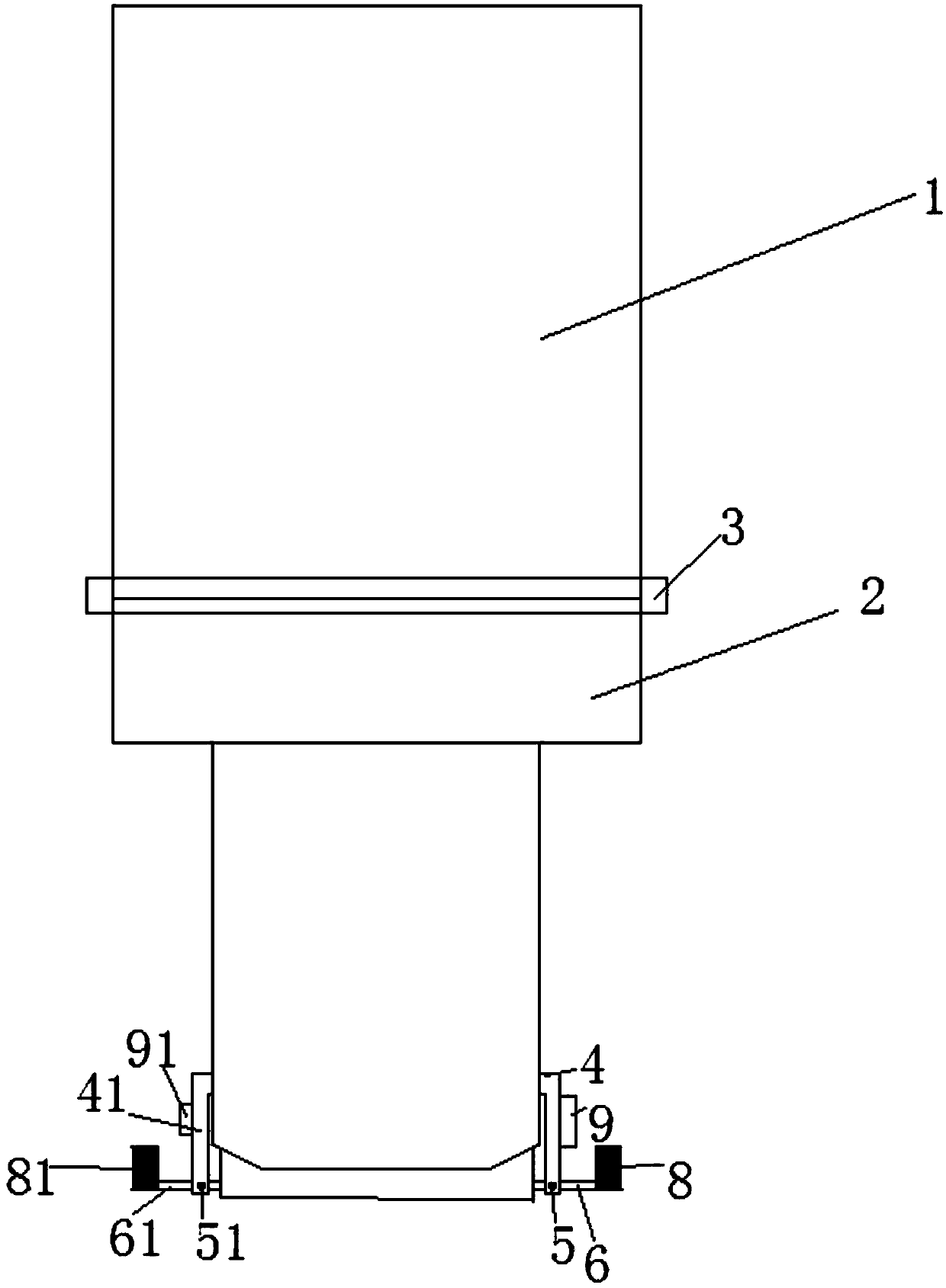

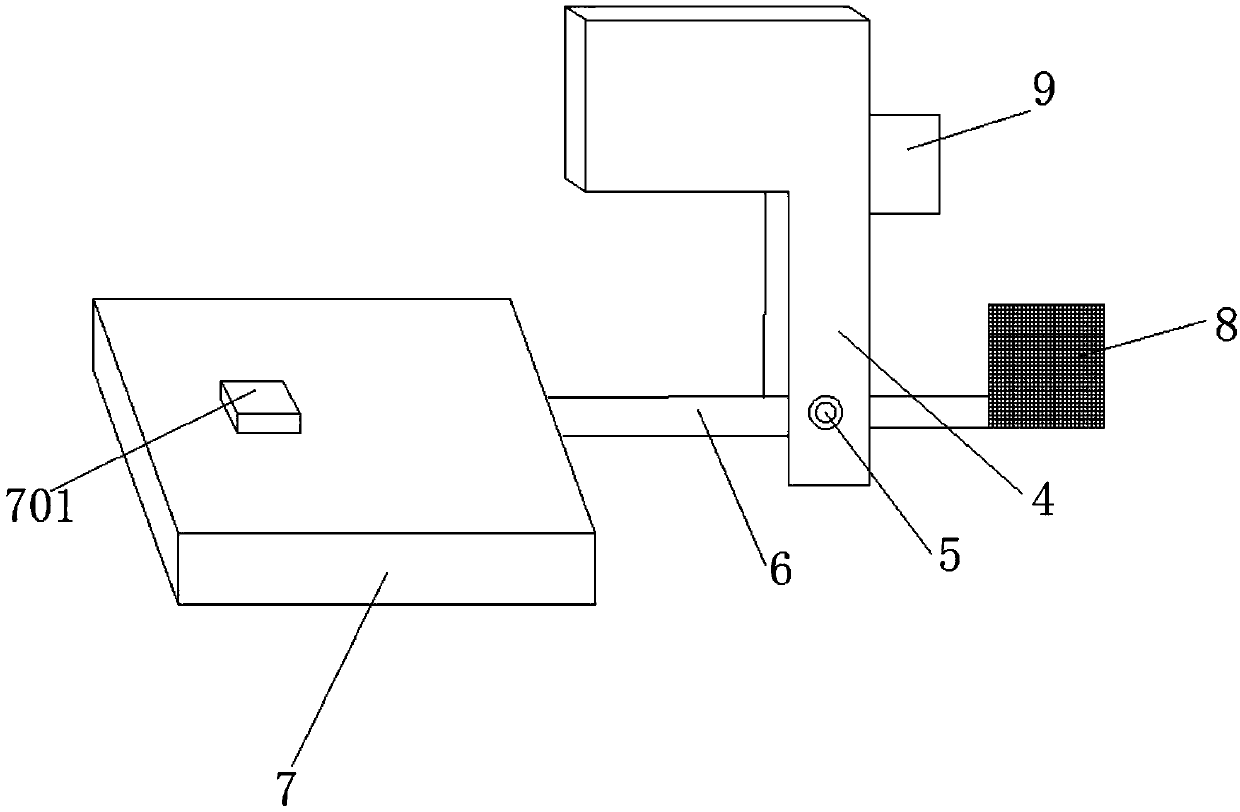

[0029] Such as figure 1 , figure 2 As shown, a filling mouth of a liquid filling machine includes a filling mouth end 1 and a filling head 2, the filling mouth end 1 is connected to the filling head 2, and the filling head 2 The outer wall is provided with a first bracket device 41 and a second bracket device 4, the first bracket device 41 is connected to the first wheel shaft 51, and the first wheel shaft 51 is connected to a rotatable first balance bar 61, so Both ends of the first balance bar 61 are respectively connected with a first baffle plate 71 and a first iron block 81; the second support device 4 is connected with the second wheel shaft 5, and the second wheel shaft 5 is connected with a The second balance pole 6, the two ends of the second balance pole 6 are respectively connected with the second baffle plate 7 and the second iron block 8, the first baffle plate 71 and the second baffle plate 7 are located in the tank Bottom of the head.

[0030] When the filli...

Embodiment 2

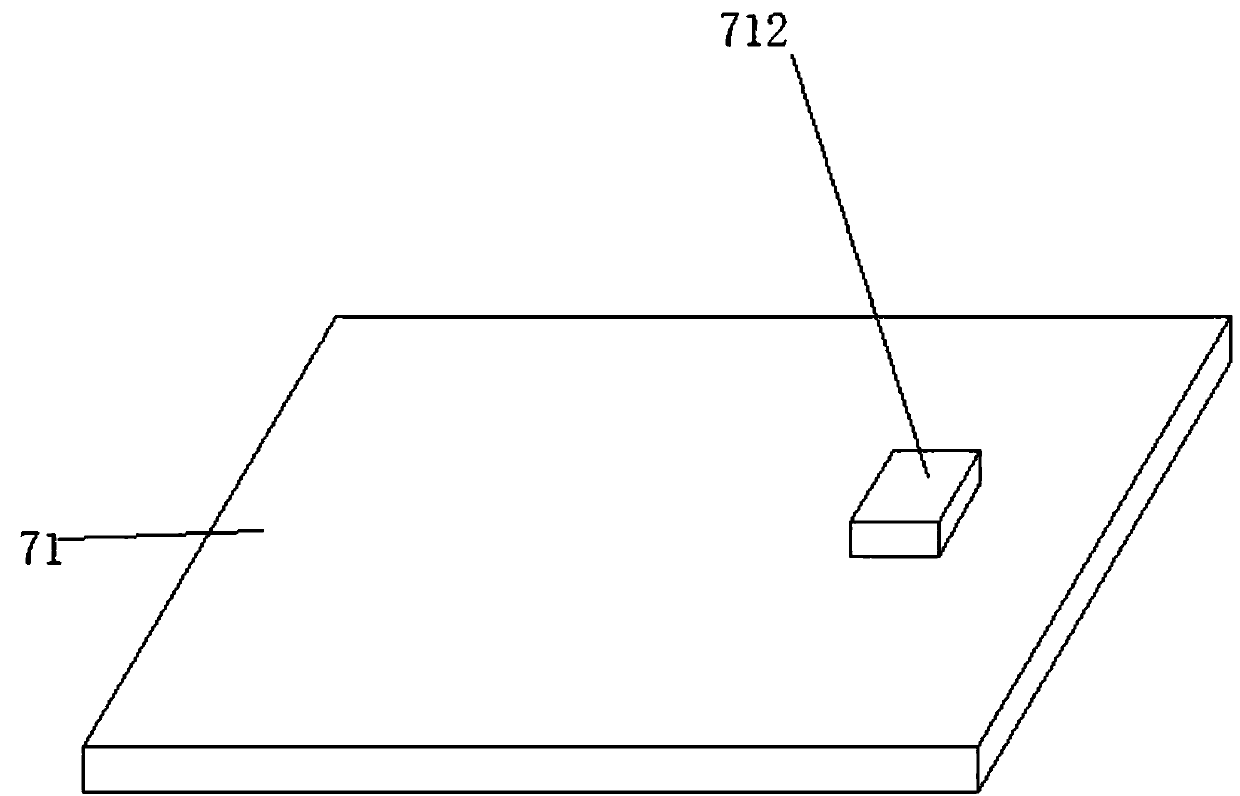

[0032] Based on Example 1, image 3 , Figure 4 As shown, the upper surface of the first baffle 71 is provided with a first protrusion 712, and the lower surface of the first baffle 71 is provided with a first groove 711; the upper surface of the second baffle 7 is provided with a The second protrusion 701 matched with the size of the first groove 711, the lower surface of the second baffle plate 7 is provided with a second groove matched with the size of the first protrusion 712;

[0033]When the filling is completed, the force exerted by the liquid on the first baffle 71 is smaller than the force exerted by the first iron block 81 on the first balance bar 61, so that the first baffle 71 moves toward the bottom of the filling head 2, and similarly The second baffle 7 also moves towards the bottom of the filling head 2 , so that the first baffle 71 and the second baffle 7 return to the bottom of the filling head 2 . Since the upper surface of the first baffle plate 71 is pro...

Embodiment 3

[0035] Based on Example 1, such as figure 1 , figure 2 As shown, the first support device 41 is provided with a first support rod, the other end of the first support rod is in contact with the first baffle 71, and the second support device 4 is provided with a second support rod 10 , the other end of the second support rod 10 is in contact with the second baffle plate 7 . Since the first support device 41 is provided with a first support rod, and the other end of the first support rod is in contact with the first baffle plate 71, when the first baffle plate 71 moves to the bottom of the filling head 2, the first support rod prevents the The movement of the first baffle 71 is ensured, so that the first baffle 71 is fixed at the bottom of the filling head. Similarly, the movement of the second baffle 7 is also prevented by the second support rod 10, so that the second baffle 7 is also fixed. At the bottom of filling head 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com