Energy-saving defrosting system of air source heat pump and control method for energy-saving defrosting system

An air source heat pump and defrosting technology, which is applied to heat pumps, refrigerators, refrigeration components, etc., can solve the problems of general defrosting effect, frost on the surface of heat exchangers, and low heating energy efficiency of the unit, and achieve the defrosting effect. Completely improve the subcooling degree of the unit and save the power consumption of the unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

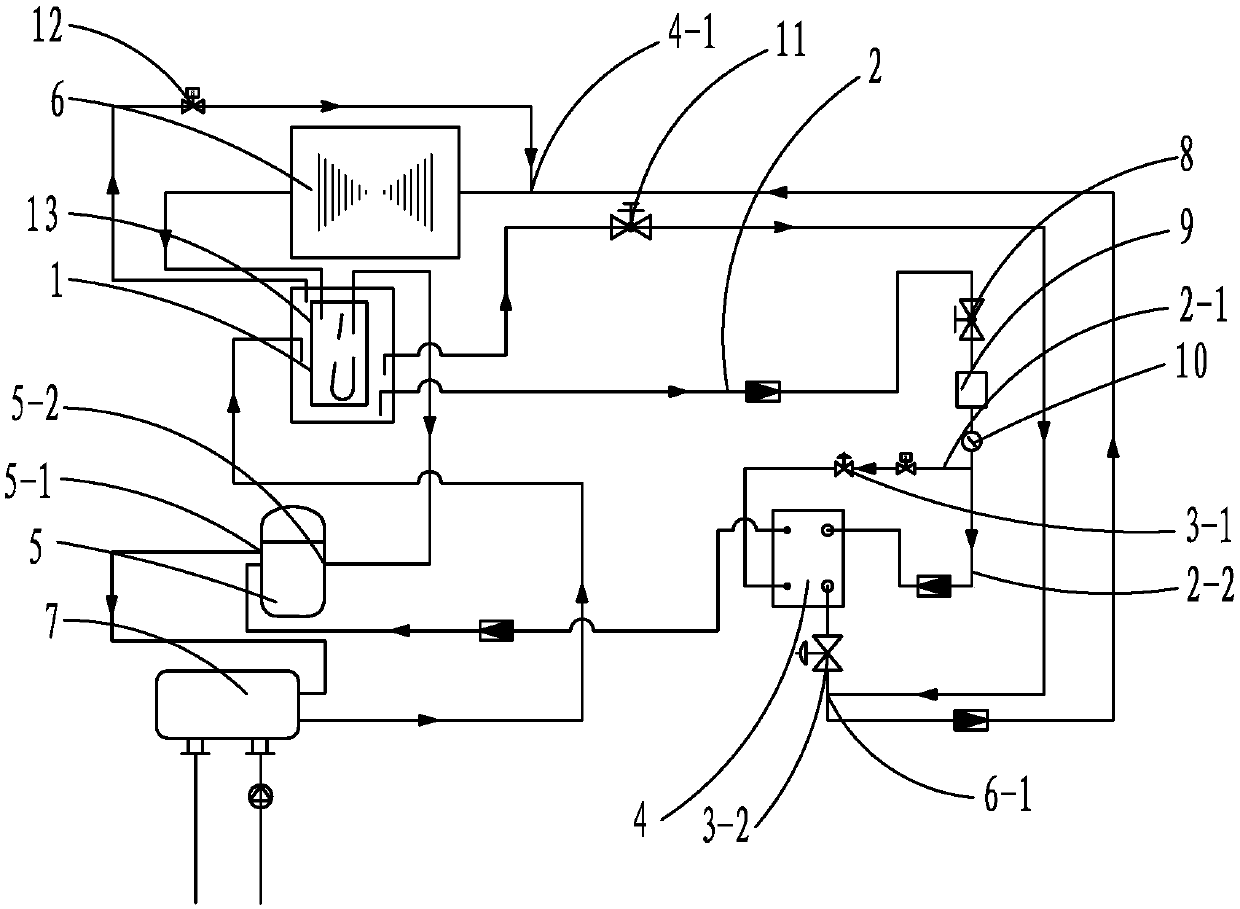

[0017] A defrosting system for an air source heat pump, comprising a three-in-one defrosting gas separation liquid storage 1, one side of the three-in-one defrosting gas separation liquid storage 1 is connected to a first pipeline 2, and after the first pipeline 2 Divided into two branches, the first branch 2-1 is connected to the first electronic expansion valve 3-1 and the economizer 4, the second branch 2-2 is directly connected to the economizer 4, and the three-in-one defrosting gas separator liquid storage 1 is also connected to the suction port 5-1 of the compressor 5, the finned evaporator 6 and the condenser 7, the exhaust port 5-2 of the compressor 5 is connected to the condenser 7, and the economizer 4 is also connected to the finned evaporator 6 , the two branches of the three-in-one defrosting gas separator 1 are respectively connected to the connection end a4-1 and the connection end b6-1 of the economizer 4 and the finned evaporator 6, and the compressor 5 is con...

Embodiment 2

[0021] When the external temperature is lower than 0°C during the heating process, frost is formed on the finned evaporator 6, and the heating energy efficiency of the unit is low, so it is switched to the defrosting mode, and the defrosting solenoid valve 11 is activated to divide the three-in-one defrosting gas into liquid storage A small amount of incompletely condensed high-temperature and high-pressure gaseous refrigerant at the top of the evaporator 1 is introduced into the inlet of the finned evaporator 6 for initial anti-frost treatment. When the temperature of the finned evaporator 6 continues to drop below -5°C, the triple 1. The 80°C liquid high-temperature refrigerant in the defrosting gas separator liquid storage tank 1 flows out to the connection end b6-1, and the 80°C high-temperature liquid refrigerant undergoes heat exchange with the low-temperature gas-liquid mixed refrigerant inside the economizer cylinder 13, 65 The liquid high-temperature agent at ℃-70 ℃ is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com