Method for producing fiber webs and production line for producing fiber webs

一种纤维幅材、生产线的技术,应用在纤维幅材在压光机中的至少一个压光压区中被压光,生产纸板幅材,压光机的生产线领域,能够解决干燥能力有限、限制纸板机速度等问题,达到节省松厚度、高生产速度、节省原浆的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

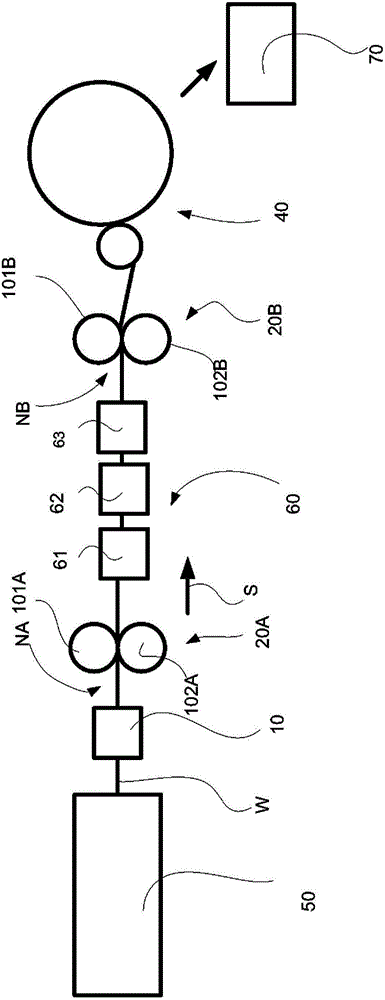

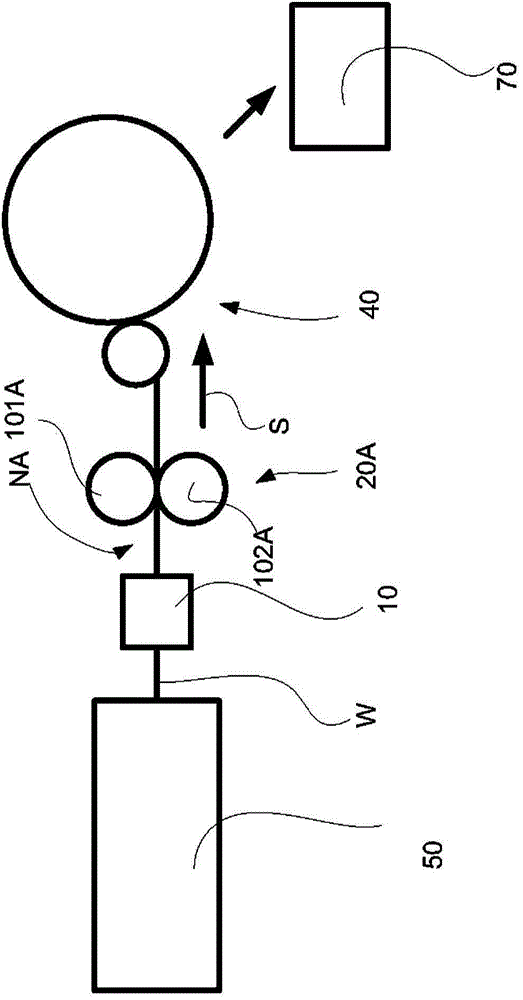

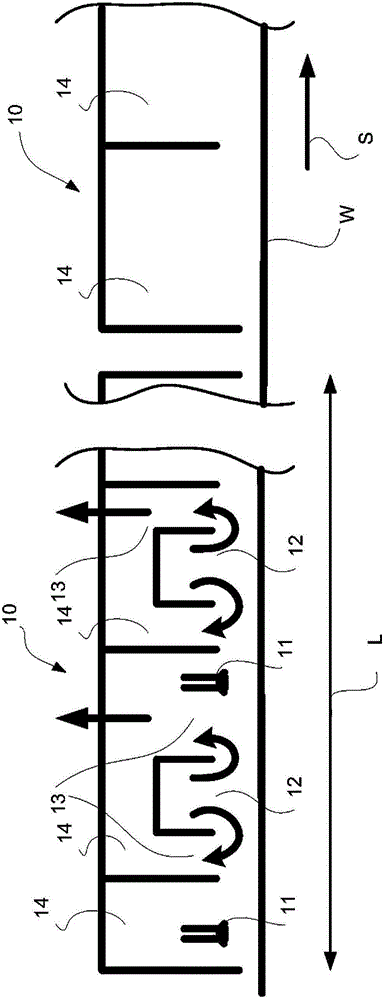

[0076] In a very schematic example of a production line for the production of coated fiber webs, in particular for the production of coated paperboard webs, such as Figure 1A As shown, the start of the production line and components are indicated by the reference numeral "50". The start of the production line for the fibrous web W and the apparatus 50 comprise a headbox, a forming section, a press section, a drying section and may also comprise a size press. These devices and parts can be constructed in many different designs and configurations known to those skilled in the art. The line also includes a finishing section having finishing sections and equipment that can be constructed in a variety of different designs and configurations known to those skilled in the art. According to the invention, the production line also comprises: at least one calender 20A with at least one calendering nip NA formed between two calender rolls 101A, 102A; and a make-up evaporative cooling m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com