Electrical washing machine with electrobath being installed

An electrolytic cell and washing machine technology, applied in the field of washing machines, can solve the problems of long delivery time, difficulty in quickly cutting off droplets, and inaccurate delivery of liquid detergent, and achieve the effects of high delivery accuracy and short delivery time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

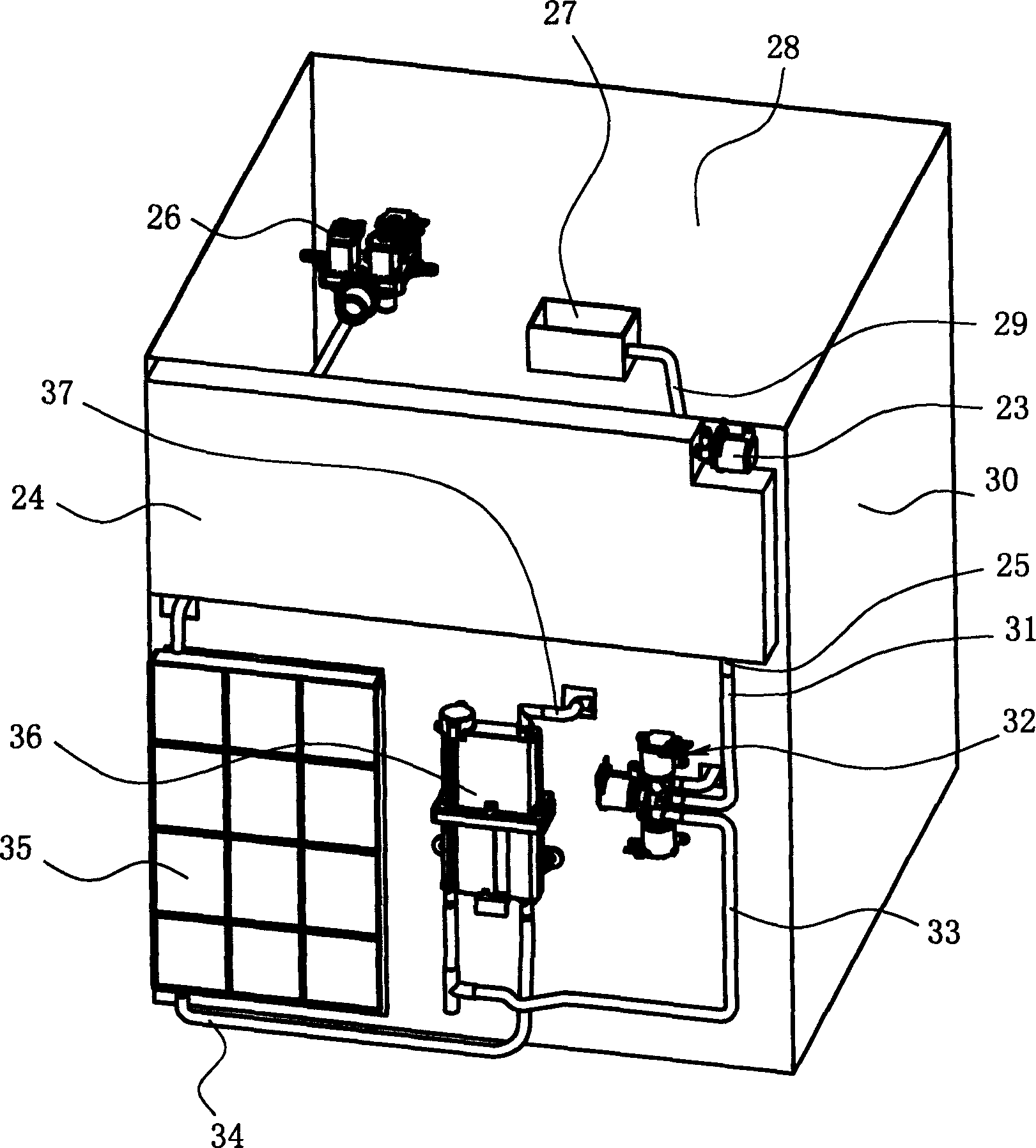

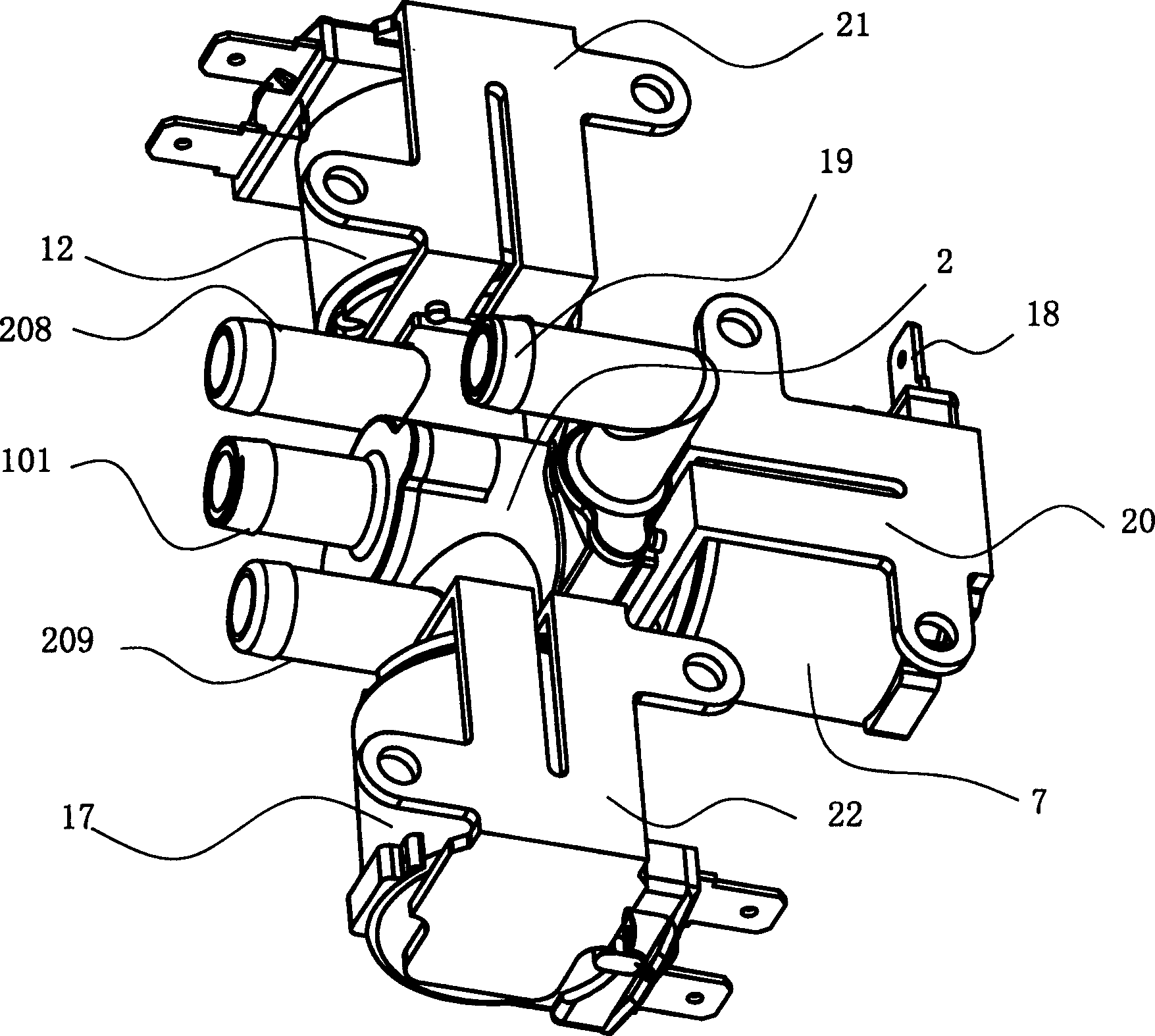

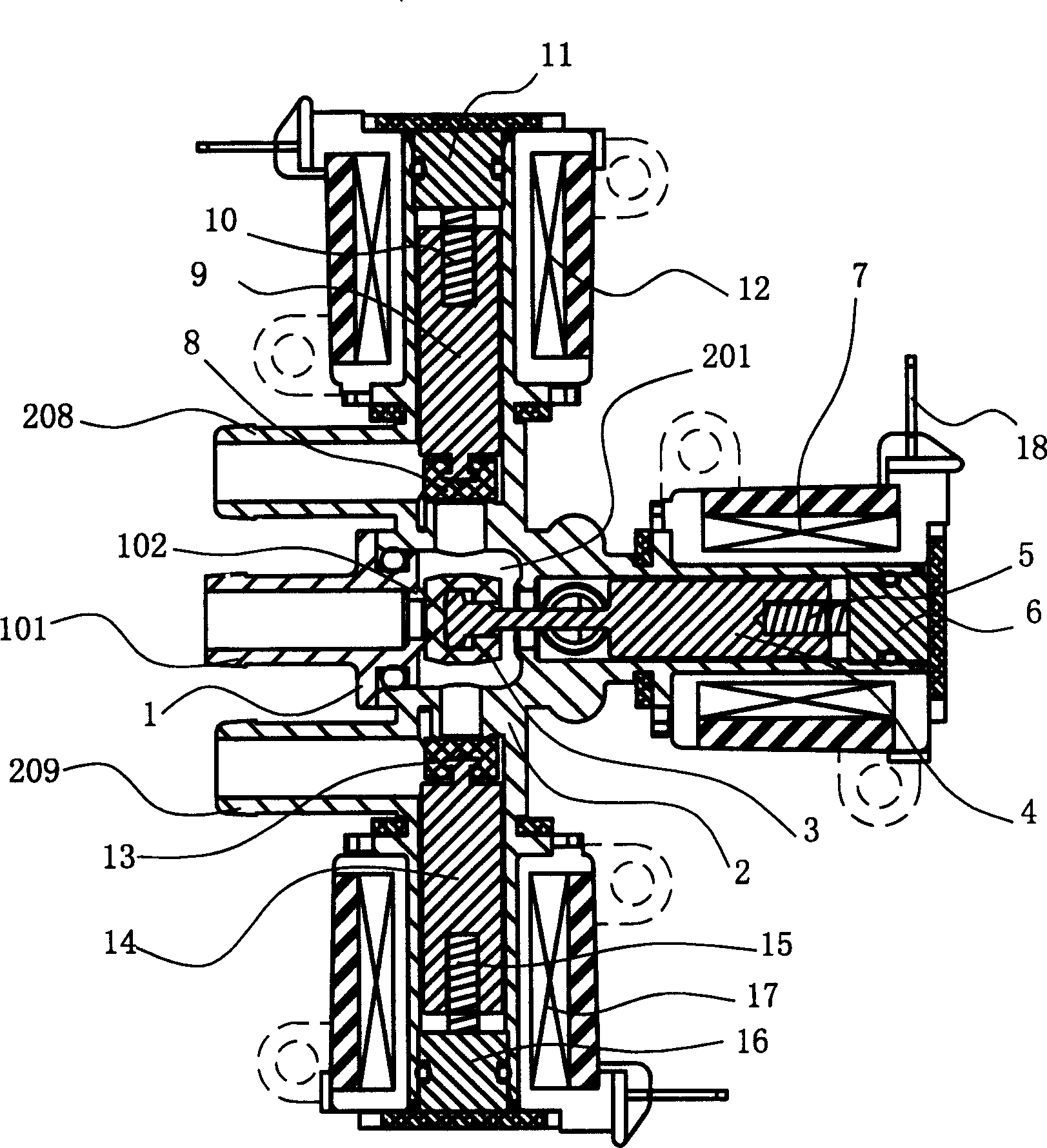

[0037]An electric washing machine equipped with an electrolytic tank, the casing 30 is provided with a washing tank 28 composed of an outer tank and an inner tank driven by a motor, an electromagnetic water supply valve 26 and a control circuit device 35, and the casing 30 is provided with an electrolytic tank 36, washing Agent tank 24 and square switching valve 32;

[0038] The electrolytic cell 36 is provided with a cathode plate electrically connected to the cathode plate electrode terminal 362 and an anode plate electrically connected to the anode plate electrode terminal 363 in its cell body, and the electrolytic cell 36 is provided with a water inlet 361, an anode outlet 364 and a cathode outlet 365;

[0039] The upper part of the detergent tank 24 is provided with an air intake valve 23, and the lower part is provided with a detergent outlet 25. The valve body of the air intake valve 23 is provided with an air inlet nozzle 231 and an air outlet connected to the detergent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com