Three-rib type micro pneumatic valve

A pneumatic valve and three-rib technology, applied in the direction of fluid flow, mechanical equipment, etc., can solve the problems of low efficiency and increase of dynamic passive valves, and achieve the effects of low cost, long life and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

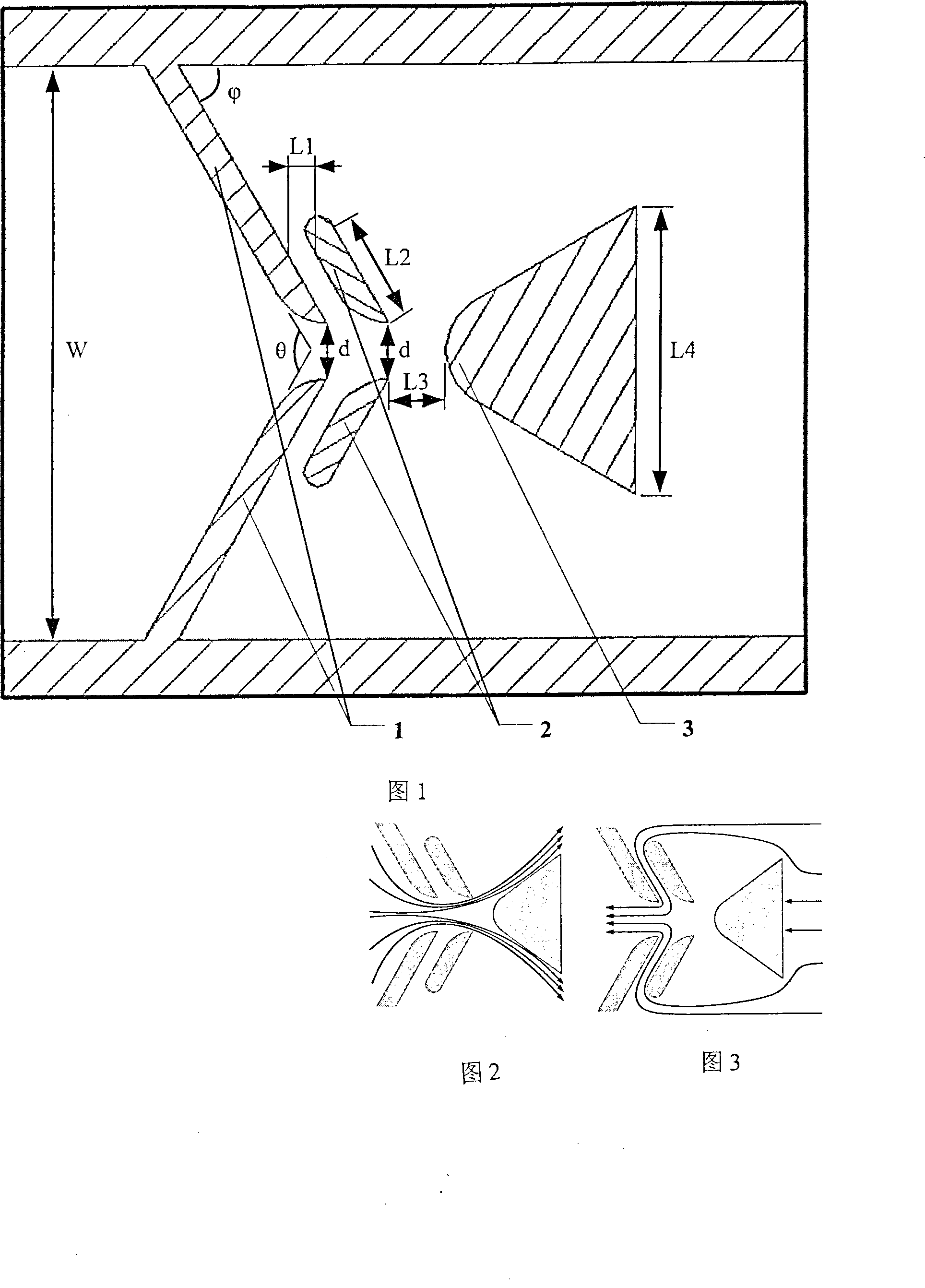

[0020] First, copper is used as the electrode material, and the electrode shown in Figure 5 is obtained through the wire cutting process. Then, the duralumin is used as the structural material, and the three ribs shown in Figure 6 are obtained by the EDM process. Type miniature pneumatic valve. The size of each part is specified as follows according to the proportions in the specific implementation manner:

[0021] The width d of the first and second rib nozzles is 1mm, the internal width W of the micro-valve is 10mm, the convergence angle θ of the first and second rib is 120 degrees, the angle φ between the downstream inclined wall of the first rib 1 and the horizontal wall is 60 degrees. The radius R1 of the transition arc segment of the primary rib 1 is 1mm, the central angle α1 of the transition arc segment of the primary rib 1 is 60 degrees, the horizontal distance L1 between the primary rib 1 and the secondary rib 2 is 0.3 mm, and the secondary rib 2 is inclined The len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com