Thrust washer and torque converter containing the same

A thrust washer and torque converter technology, applied in couplings, clutches, clutches, etc., can solve problems such as failure and torque converter performance degradation, and achieve the effects of slowing down flow, increasing flow, and reducing turbulence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

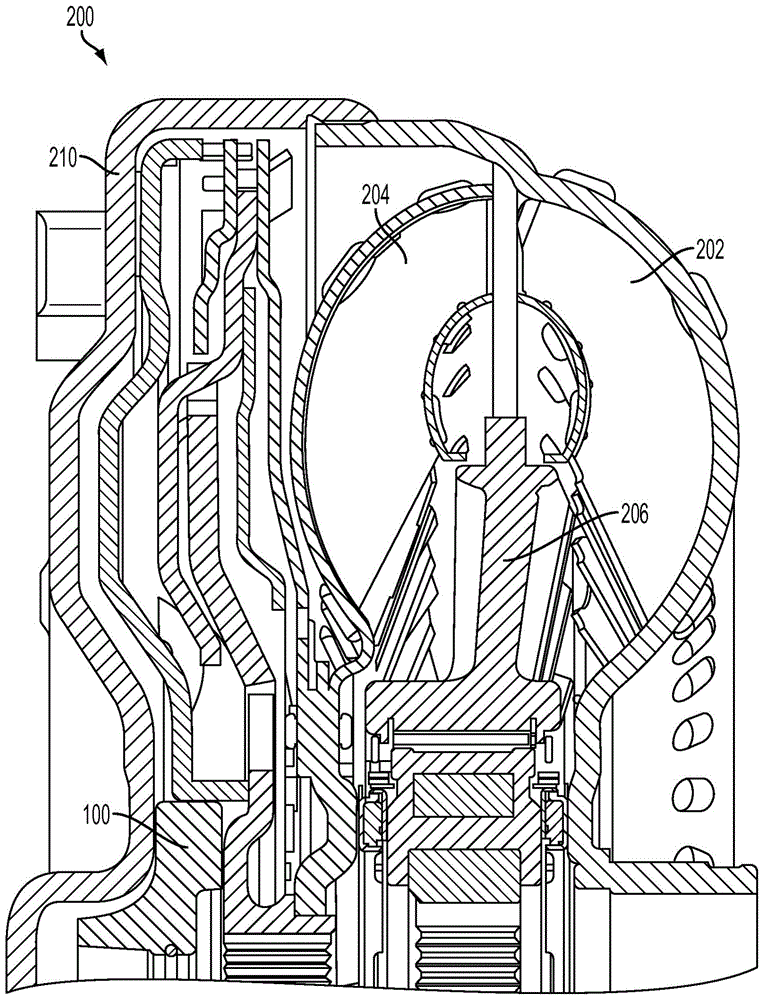

[0022] figure 1 is a cross-sectional view of torque converter 200 showing the locations of thrust washer 100 , impeller 202 , turbine 204 , stator 206 , and cover 210 . Embodiments of the thrust washer contemplated herein provide more desirable fluid flow within the torque converter. During operation of torque converter 200 , torque generated from an engine (not shown) drives impeller 202 . Cover 210 is attached to impeller 202 so both cover 210 and impeller 202 rotate at the same speed as the engine. Turbine 204 is connected to an output shaft (not shown), which, when used in automotive applications, is the input shaft of a transmission (not shown). Turbine 204 and impeller 202 have blades oriented such that as impeller 202 rotates, fluid within torque converter 200 is forced into the blades of turbine 204 , transferring energy to turbine 204 and forcing it to rotate.

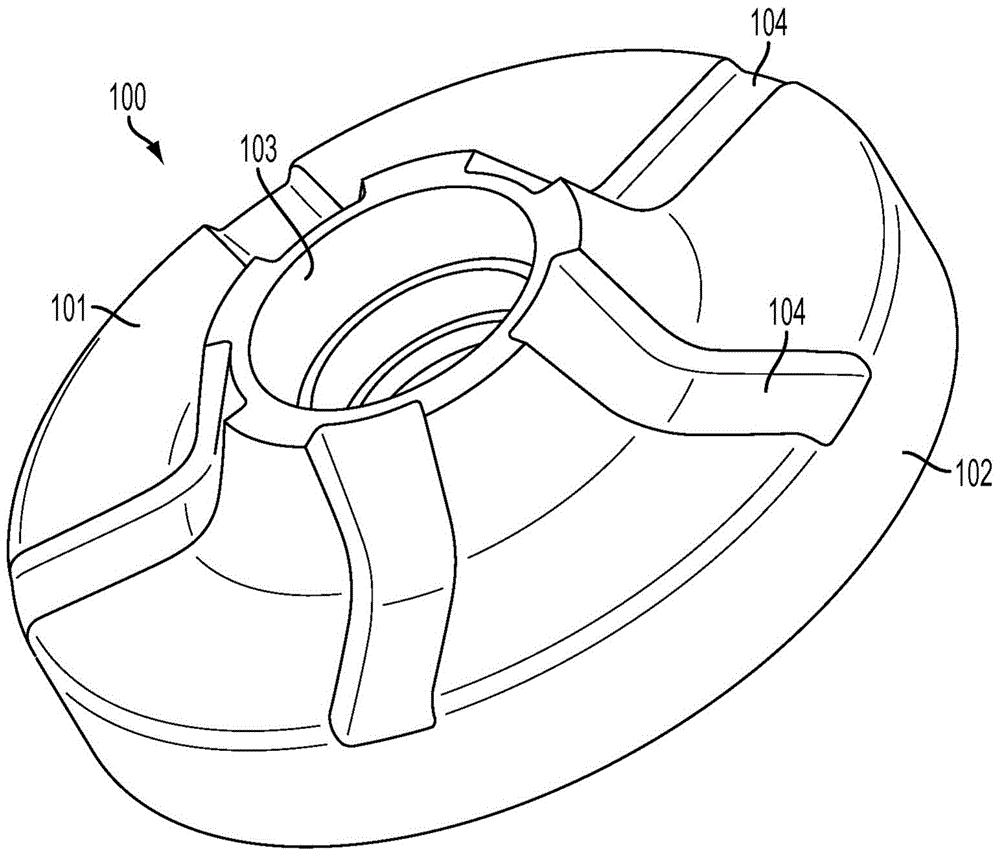

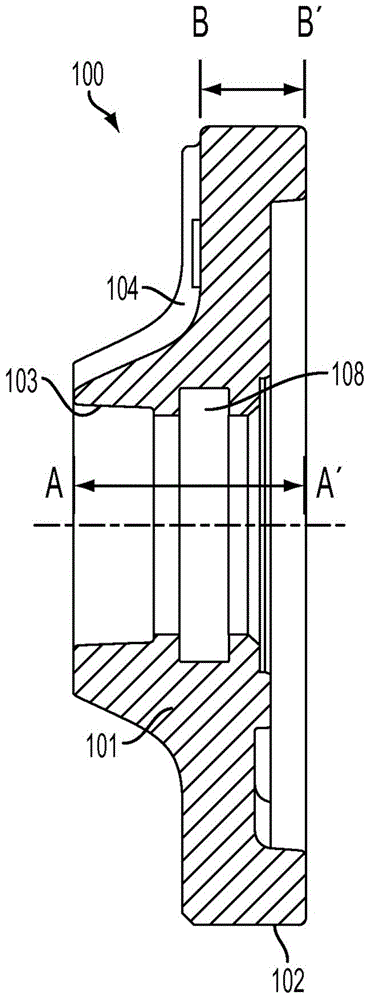

[0023] figure 2 and image 3 A thrust washer 100 according to the present embodiment is shown. A thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com