Regenerative media filtration

a technology of regenerative media and filter elements, applied in the direction of filtration separation, loose filtering material filters, separation processes, etc., can solve the problems of inefficient placement inefficient tank geometry, and negative filtration efficiency, so as to improve the structure of regenerative media filters and improve the effect of fluid flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

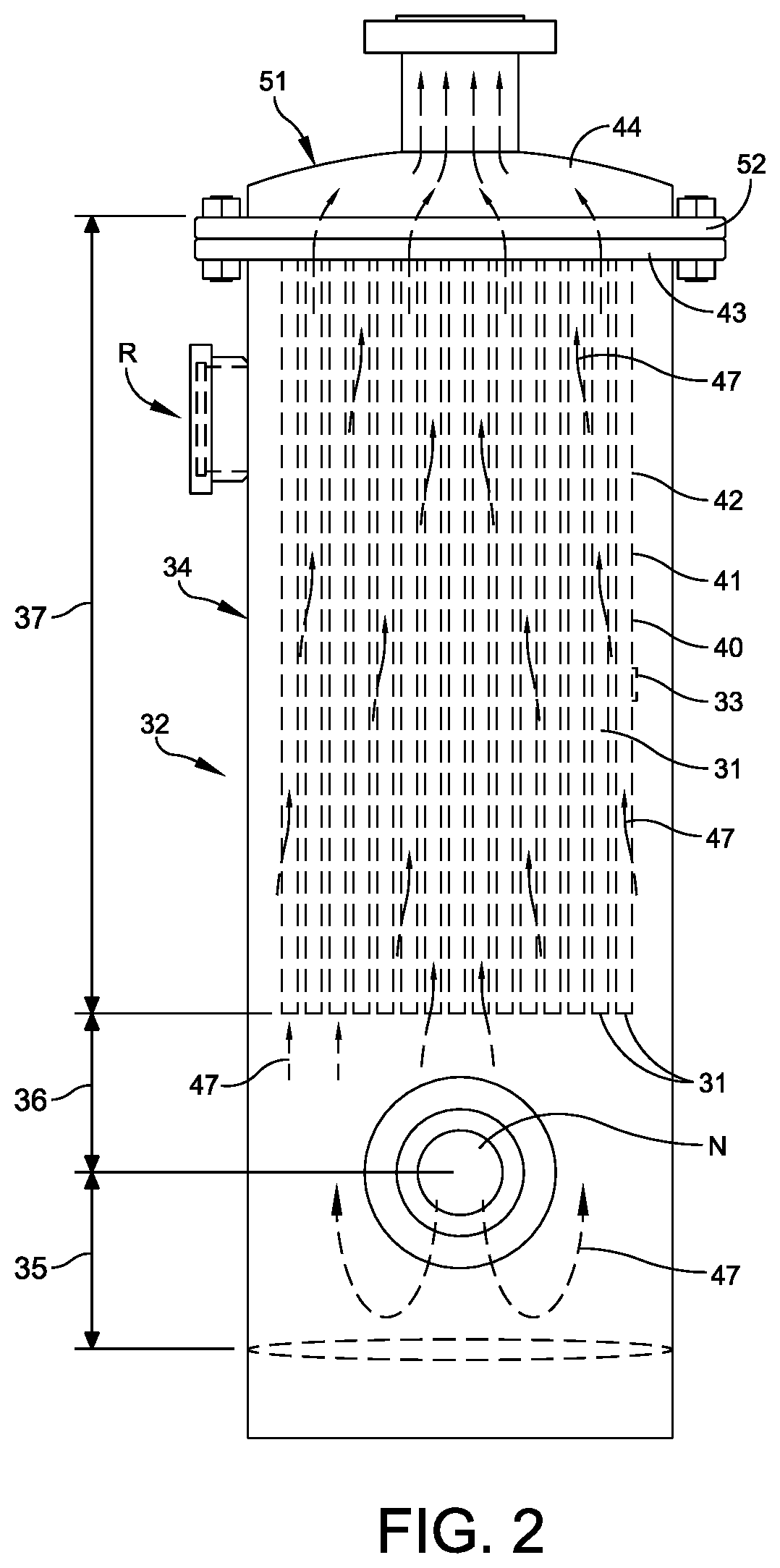

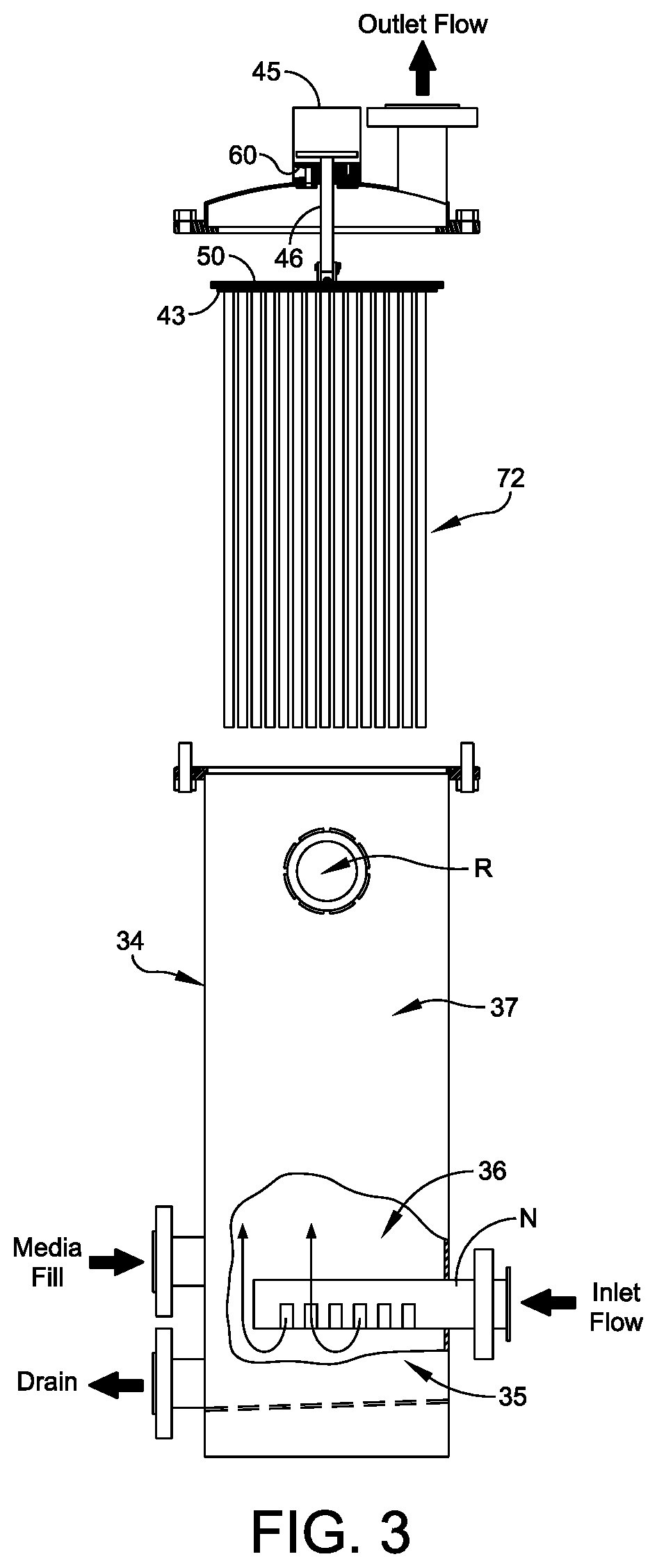

[0078]In accordance with the present invention the regenerative media filter is constructed to optimize the overall size of the filter per unit of fluid filtered and achieves this by optimizing multiple variables simultaneously, Refer in particular to FIG. 2 that illustrates a regenerative media filter in accordance with the present invention indicated generally at 32. These variables include, among possible other variables, the diameter of the filter elements 31; the planar spacing of the elements 31; the volume of regenerative media 33 that is deposited on the outer surface 40 of the filter elements 31; the resultant interstitial free space S (refer, for example, to the embodiment shown in FIG. 25) when the filter elements 31 are coated with the filtration media 33; the shell diameter of the filter housing 34; the height and volume of the inlet zone 35; the height and volume of the buffer zone 36; and the height and volume of the filtration zone 37 of the regenerative media filte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com