Viscous damper to passively adjust high energy consuming clearances

A viscous damper and high energy consumption technology, which is applied in the direction of shock absorbers, shock absorbers, liquid shock absorbers, etc., can solve the problem of excessive changes in damping force, large stress on connected components, low energy consumption efficiency, etc. problem, to achieve the effect of accelerating heat conduction and dissipation, improving efficiency and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

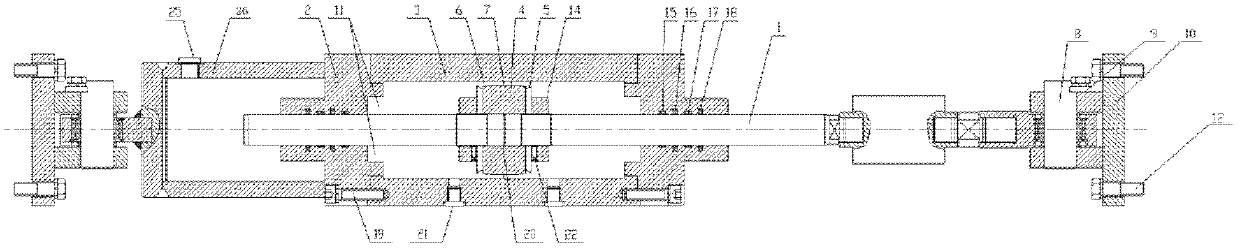

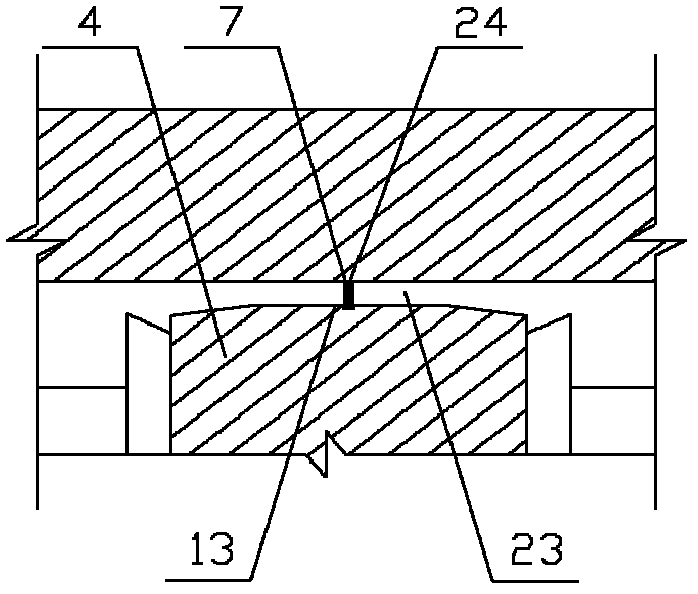

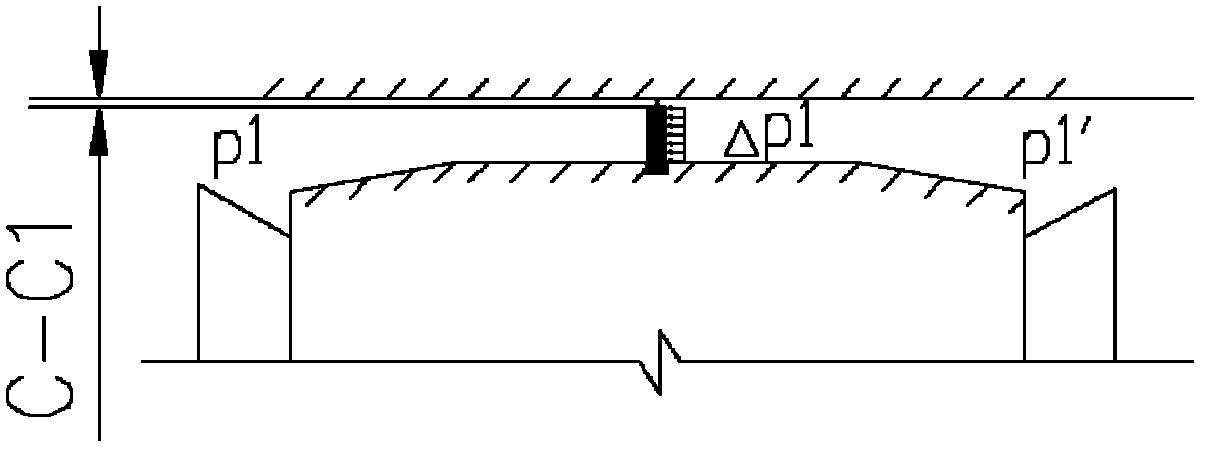

[0030] For its specific structure, see Figure 1-9 , a high energy consumption gap passively adjustable viscous damper of the present invention, comprising a piston rod 1, a cylinder head 2, a cylinder barrel 3, a piston head 4, the cylinder barrel 3 and the cylinder heads 2 on both sides form a closed cylinder body, The piston rod 1 extends into the cylinder body through the cylinder head 2 on both sides. The piston rod 1 in the cylinder body is provided with a piston head 4, and a main fluid channel 23 is formed between the piston head 4 and the cylinder barrel 3. The piston head 4 A soft metal annular valve 7 is arranged on the periphery of the middle part, and a damping gap 24 is formed between the soft metal annular valve 7 and the cylinder 3. A guide disc 5 is arranged on both sides of the piston head 4, and the edge of the guide disc 5 is inclined outward. Buffer grooves 11 are provided on both sides of the cylinder 3 . Among them, the clearance of the main fluid chann...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gap | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com