Rotor of high-speed permanent magnet motor

A permanent magnet motor and rotor technology, applied in the direction of magnetic circuit rotating parts, magnetic circuits, electrical components, etc., can solve problems such as eddy current loss of rotors that are prone to damage, insufficient permanent magnet strength, and affect the reliability of the motor, so as to avoid irreversibility Effects of demagnetization, increased heat dissipation, and increased air gap length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0021] detailed description: The present invention will be further described below in conjunction with accompanying drawing:

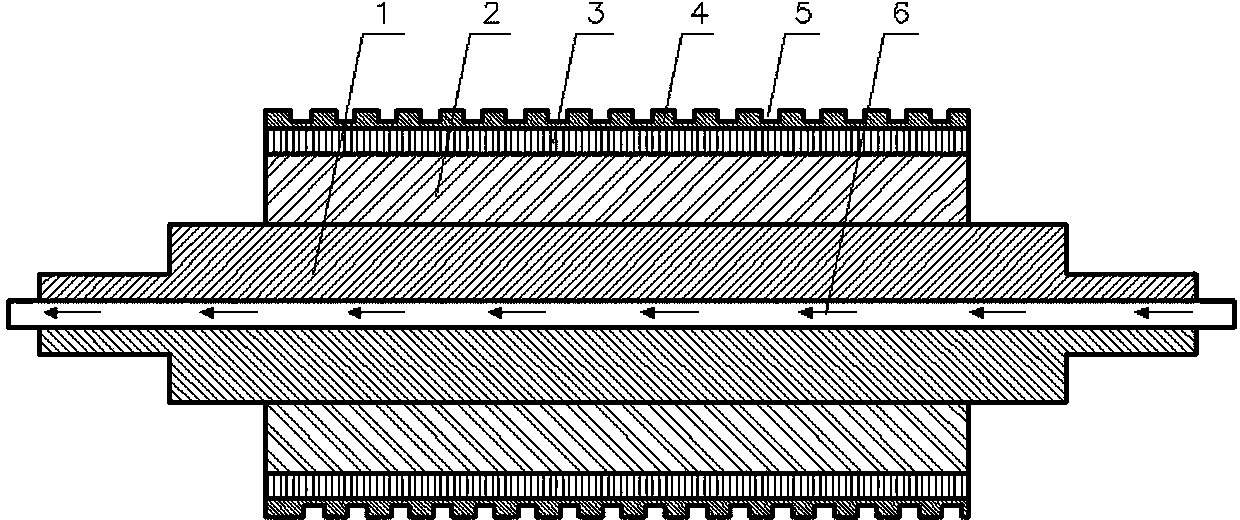

[0022] Such as figure 1 As shown, the present invention provides a high-speed permanent magnet motor rotor, including a rotating shaft 1, a rotor core 2, a permanent magnet 3 and a protective cover 4, the rotor core 2 is set on the rotating shaft 1, the permanent magnet 3 is set on the rotor core 2, and the protective cover 4 are sleeved on the permanent magnet 3, and a rotor cooling channel 6 is arranged in the rotating shaft 1.

[0023] A rotor cooling passage 6 is provided at the center of the rotating shaft 1 , and a cooling medium such as water or oil is passed into the cooling passage 6 .

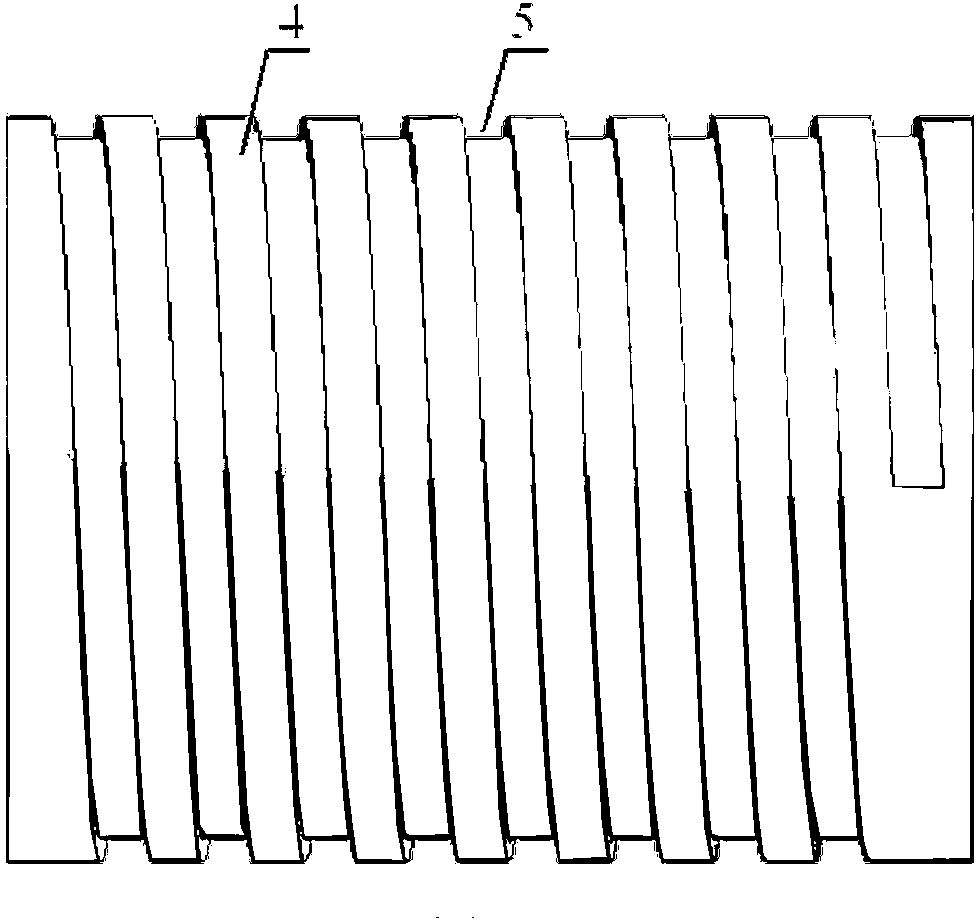

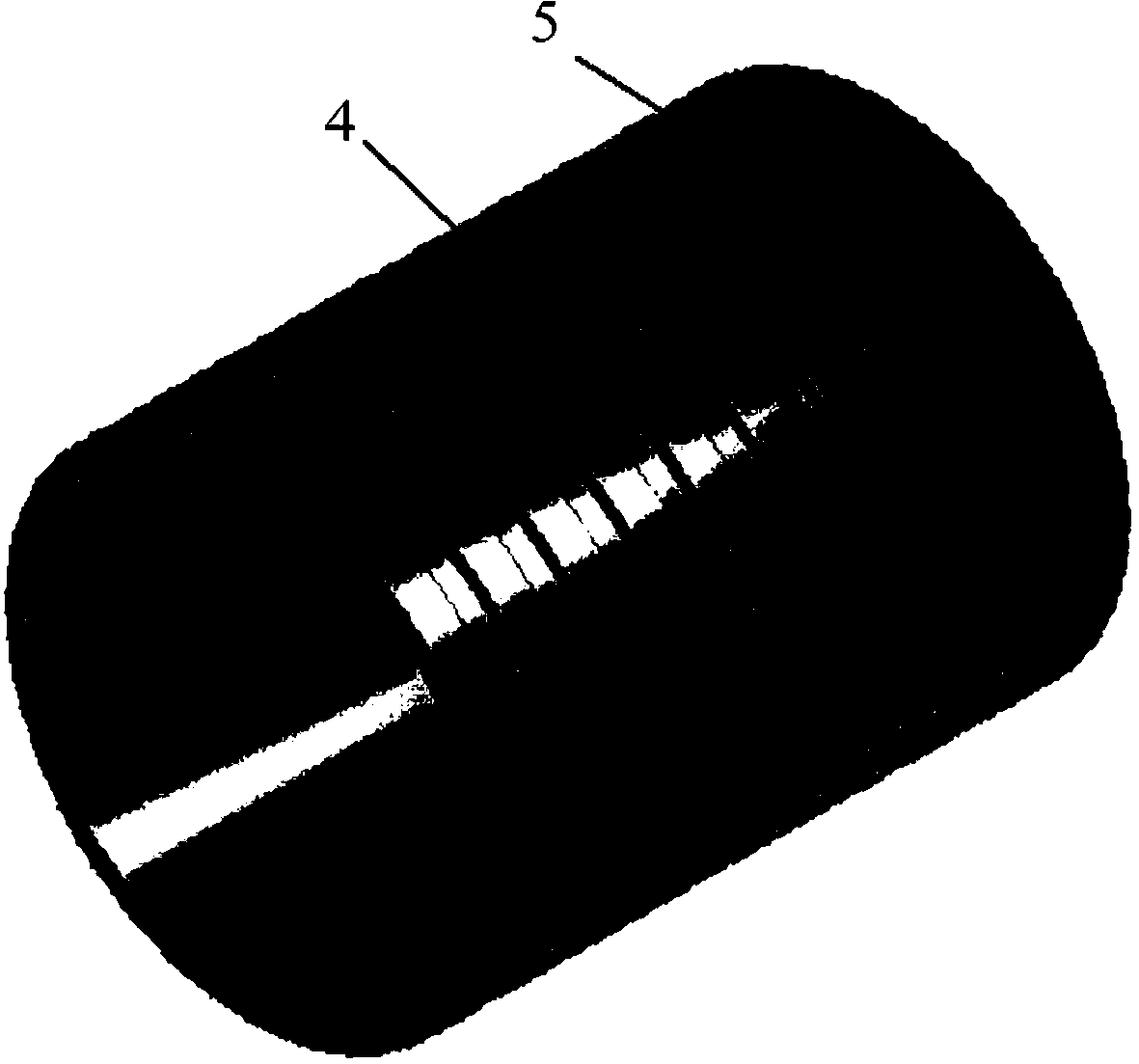

[0024] The protective sheath 4 is a semimagnetic alloy protective sheath. A spiral groove 5 is evenly opened along the outer surface of the protective cover 4 . The motor rotor adopts a surface-mounted permanent magnet 3, and the protective cover 4 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com