Integral whole-through diameter ball valve

A full-bore, integral technology, applied in the field of machinery, can solve the problems of poor safety, small flow, small valve core aperture, etc., and achieve the effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

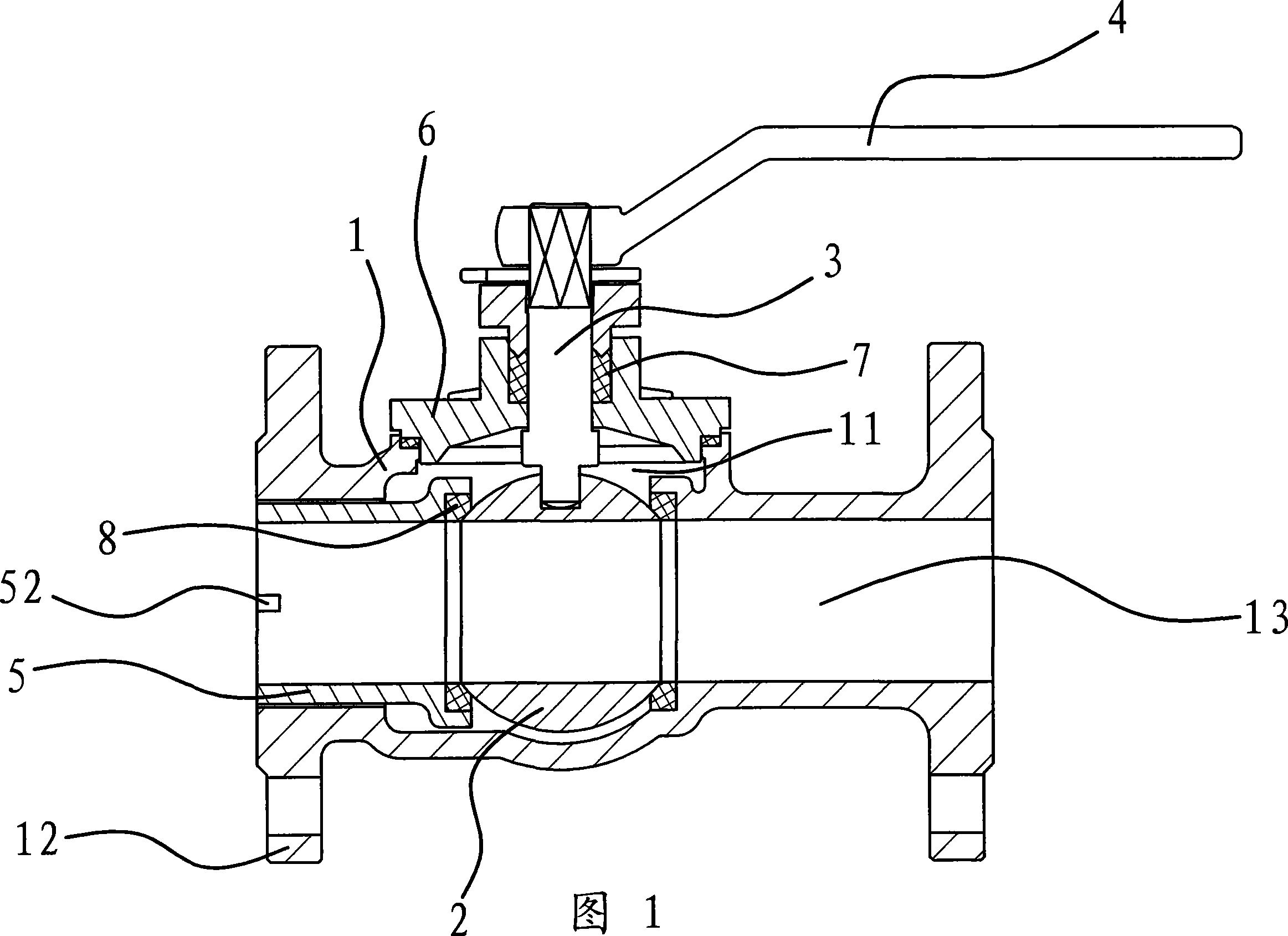

[0019] As shown in Figure 1, the integral full-bore ball valve includes a valve body 1, a valve core 2, a valve stem 3, a handle 4, a regulating valve seat 5, a gland 6, and the like.

[0020] The valve body 1 is an integral structure, and its inside has a through hole 13 passing through its two sides, and a flange 12 is provided at the port of the through hole 13 . The valve core 2 is installed in the through hole 13 of the valve body 1, the inner end of the valve stem 3 is connected with the valve core 2, the outer end of the valve stem 3 passes through the valve body 1, and the handle 4 is fixedly connected to the outside of the valve stem 3. end.

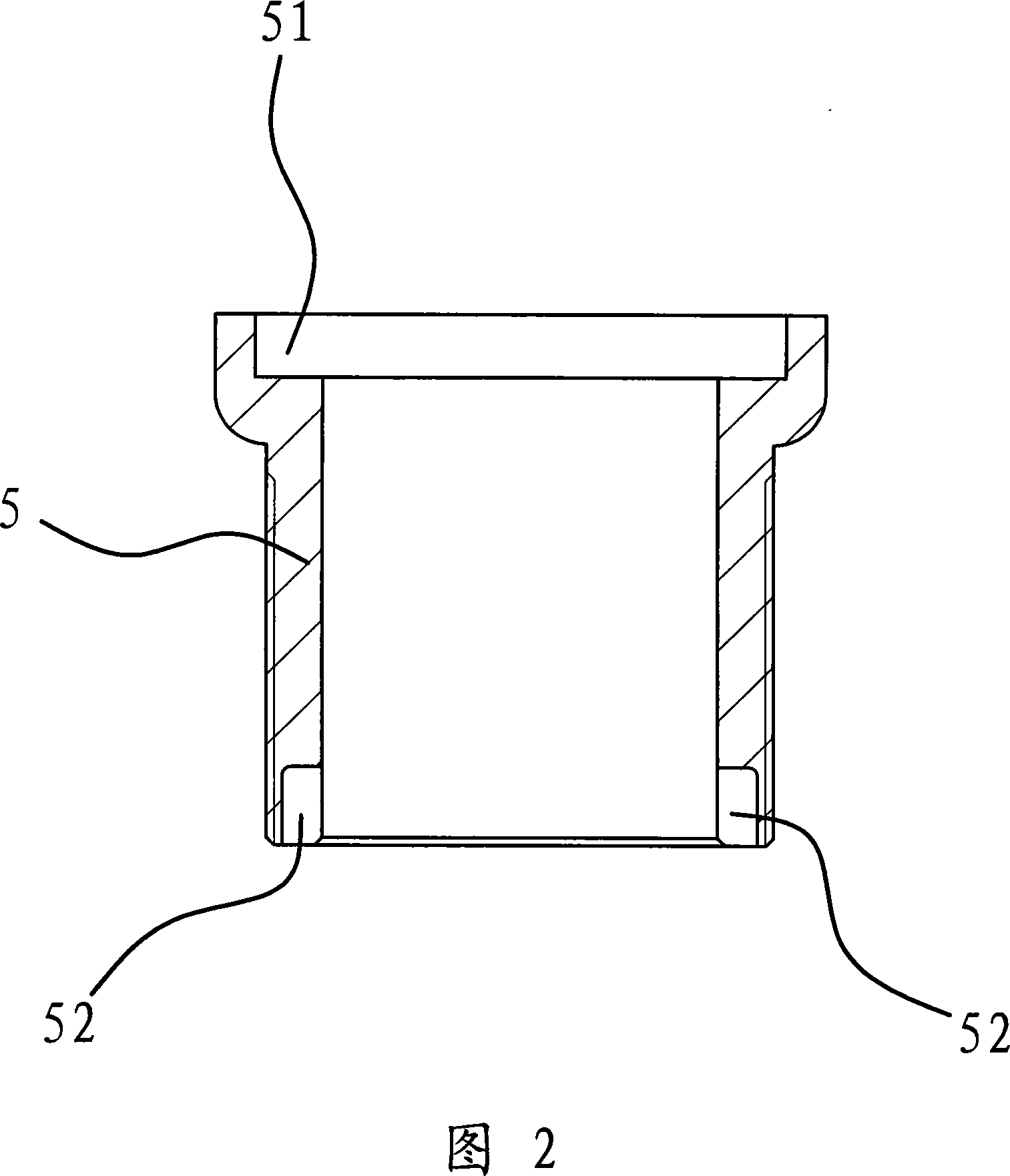

[0021] As shown in Figure 1 and Figure 2, a regulating valve seat 5 is also provided at the through hole 12 of the valve body 1, the regulating valve seat 5 is connected with the valve body 1 through threads, and one end of the regulating valve seat 5 is provided with a sealing ring Seat 51, sealing ring seat 51 is the breach t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com