Spiral-flow type jet pump

A jet pump and swirling technology, applied in the field of jet pumps, can solve the problems of high cost, high difficulty in nozzle processing, and the actual efficiency has not been substantially improved, so as to achieve the effect of increasing the flow rate of the liquid to be sucked and improving the efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

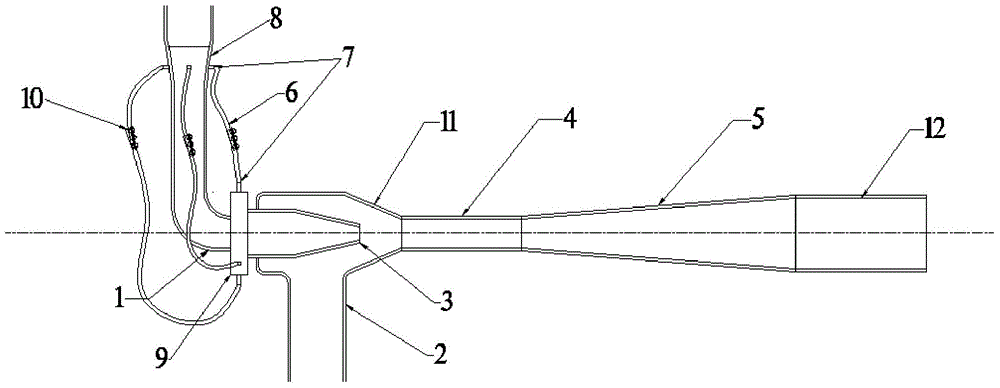

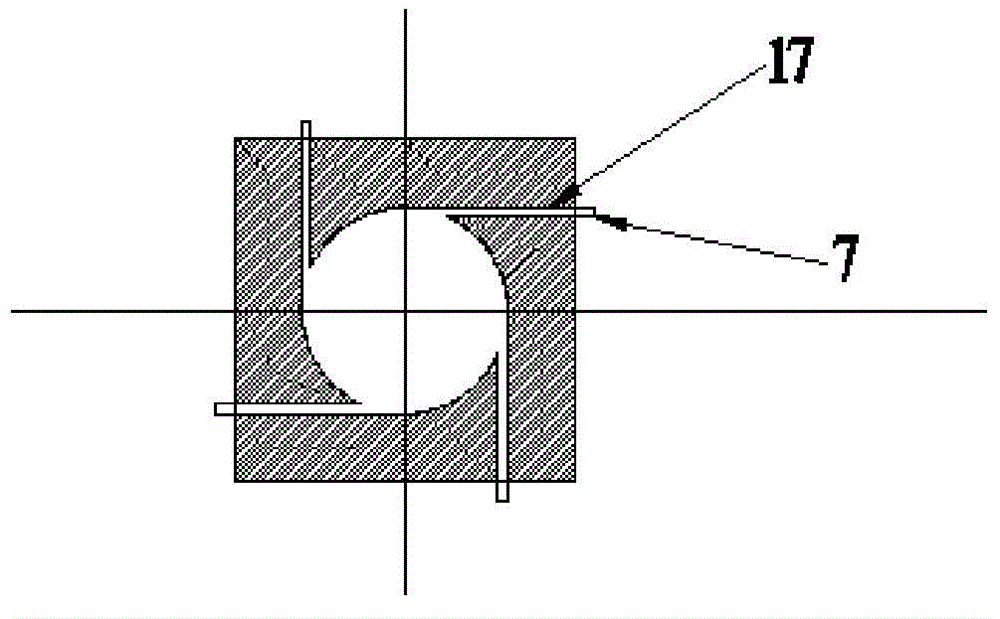

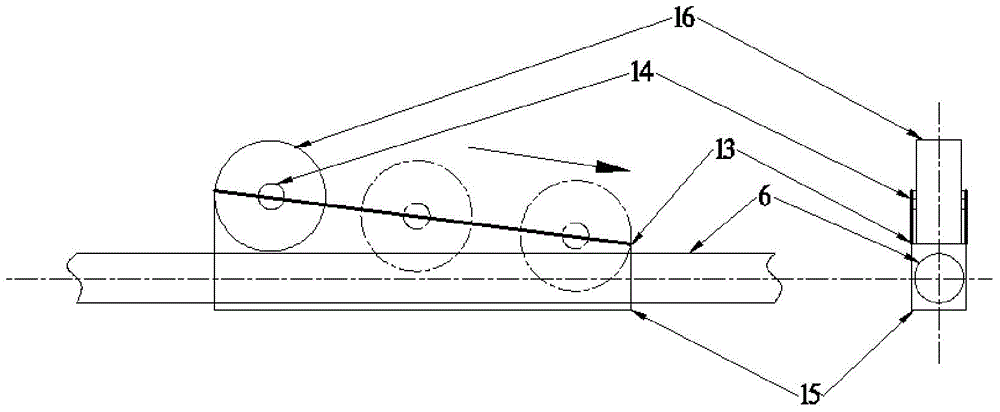

[0018] figure 1 Schematic diagram of the installation of the swirl jet pump, including water inlet pipe 1, swirl generator 9, nozzle 3, throat pipe 4, water suction pipe 2, diffuser pipe 5 and outlet pipe 12, the jet pump is installed in sequence from left to right Water inlet pipe 1, swirl generator 9, nozzle 3, water suction pipe 2, throat pipe 4, diffusion pipe 5 and water outlet pipe 12; one end of the nozzle 3 is installed in the suction chamber 11 of the water suction pipe 2; One end of the water inlet pipe 1 is connected to the swirl generator 9, and the other end is connected to a multi-way pipe 8; the outer wall of the multi-way pipe 8 is radially and uniformly provided with no less than four short pipes 7 of different diameters, so The outer wall of the swirl flow generator 9 is equally radially and uniformly provided with no less than four different-diameter sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com