Hydraulic fracture height growth control

a technology of hydraulic fracture and height growth, applied in fluid removal, chemistry apparatus and processes, borehole/well accessories, etc., can solve the problems of vertical fracture growth, fracture height control, barrier rocks will also crack, etc., and achieve the effect of reducing the viscosity, reducing the viscosity and reducing the viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

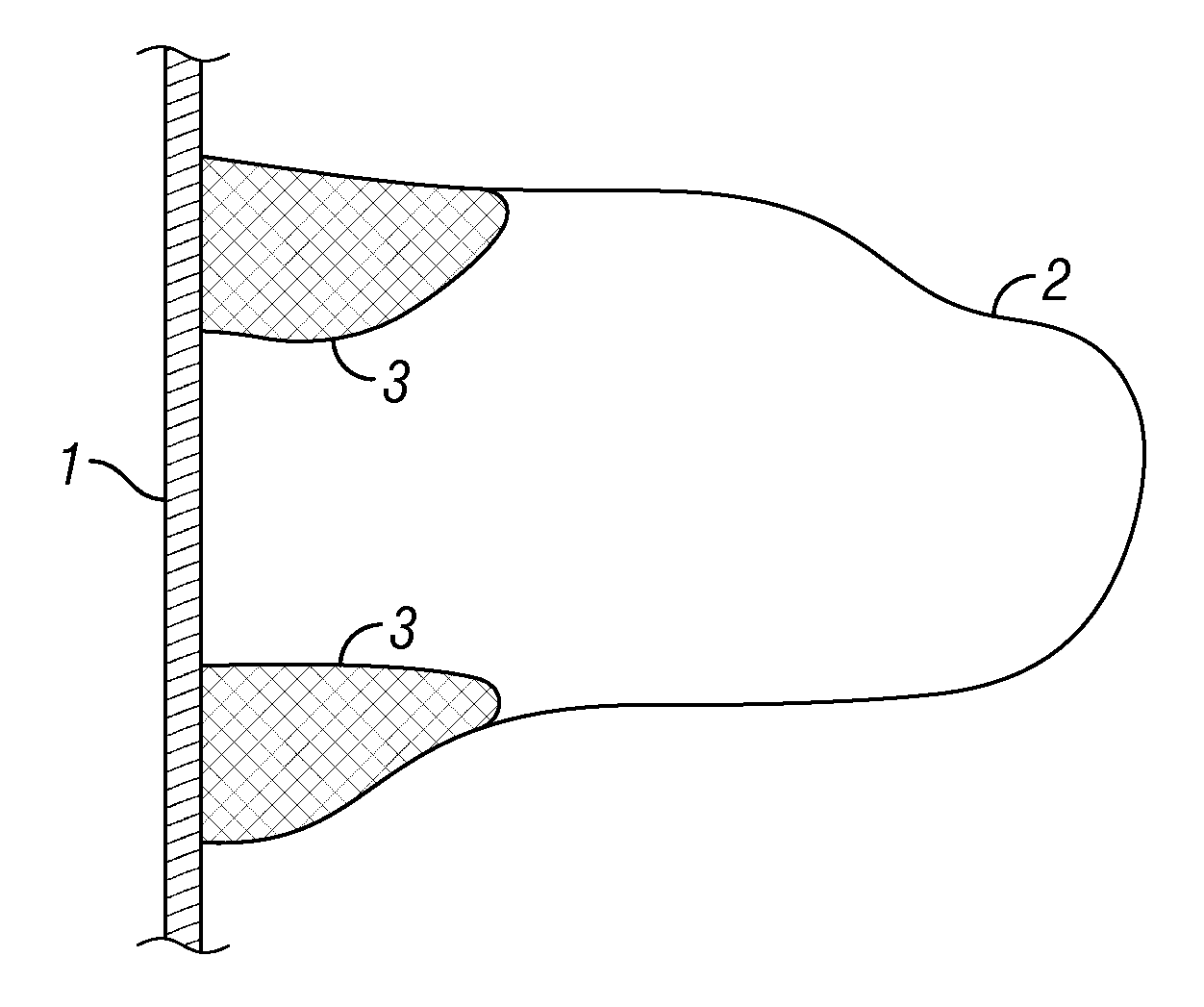

[0048]This example demonstrates how the method of the Invention performs under typical field conditions. Table 1 shows the pumping schedule and FIG. 1 demonstrates the particle concentration distribution after the end of stage 4, calculated (as in all the examples) using a pseudo 3D fracturing simulator (fracture design, prediction, evaluation and treatment-monitoring program) commercially available under the trade designation FracCADE™ from Schlumberger Technology Corporation, Sugar Land, Tex., U.S.A. The density of the barrier particles (called sand in this and the other examples) was equal to 3600 kg / m3 and the particle mean diameter was 0.589 mm (20 / 40 mesh sand). The “highly-viscous” fluid parameters were as follows: the power-law exponent was n=0.59 and the consistency was K=0.383 Pasn; the density was that of water, and the apparent viscosity was μ=28.1 cP at a shear rate equal to 170 s−1. (The fluid modeled contains 3.6 kg / m3 bromate-crosslinked guar.) The “low-viscosity” fl...

example 2

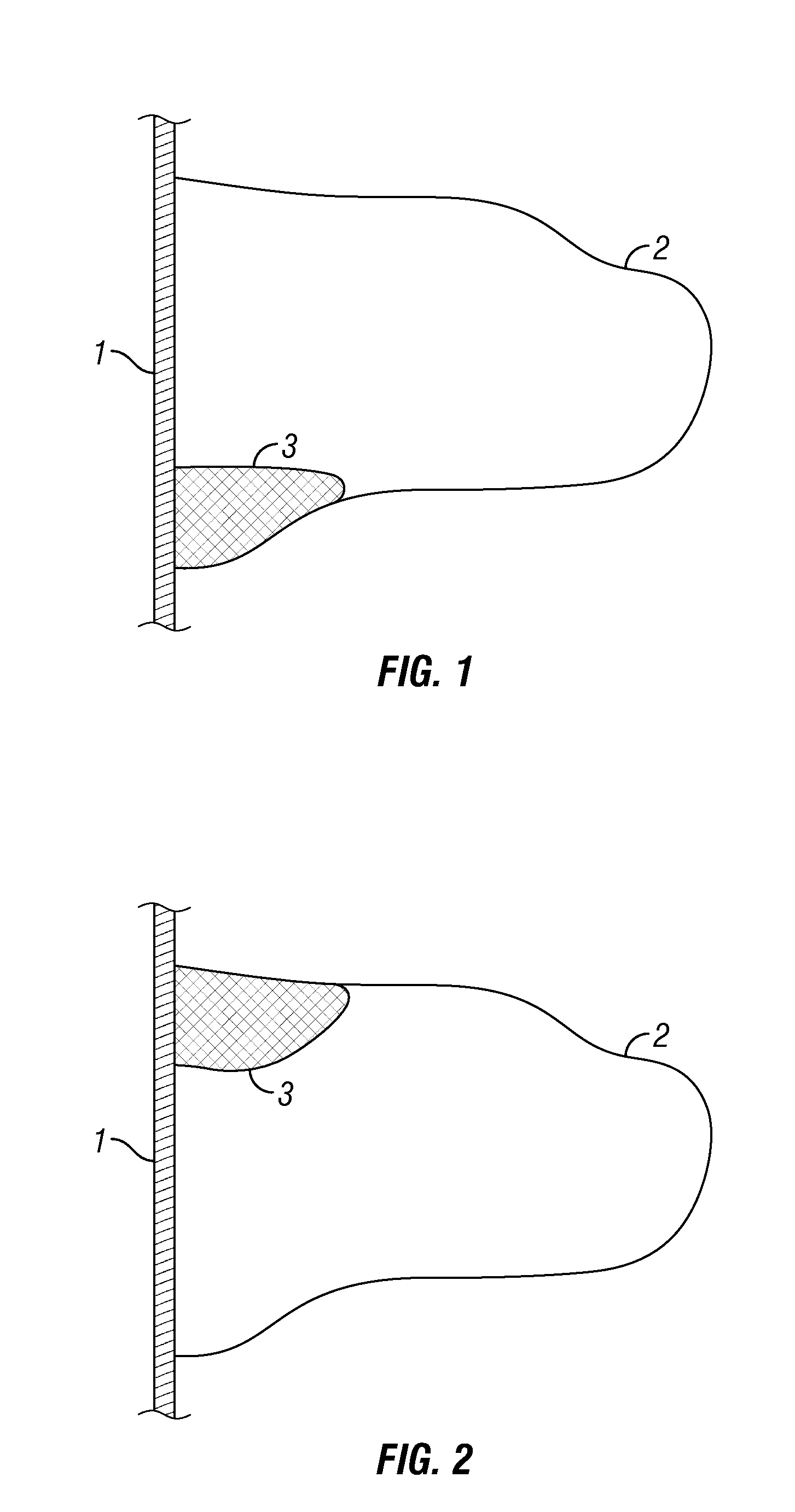

[0050]The next example illustrates the placement of a barrier stretched along the bottom edge of the fracture. In order to provide an elongated barrier, an auxiliary stage was introduced between pumping the barrier particle slug (Stage 2) and injecting the low-viscosity fluid (Stage 4 in this example). At this point (Stage 3) a small portion of clean cross-linked gel was introduced. The extended job design is presented in Table 2.

TABLE 2Treatment schedule for Example 2PumpFluidPar-Par-Slurryrate,Vol-ticleticleVol-Pumpm3 / ume,Par-Conc.,Mass,ume,Time,StageminFluidm3ticleskg / m3kgm3min16.36Low-80—008012.6visc26.36High-10Sand958.61958612.72.0visc36.36High-20—00203.1visc46.36Low-30—00304.7visc56.36High-100—0010015.7visc

[0051]The particle concentration distribution calculated for this job design is shown in FIG. 8. It can be seen that the small stage of clean viscous fluid pushed a portion of the barrier slug farther into the fracture. This job design was optimized for this effect by runnin...

example 3

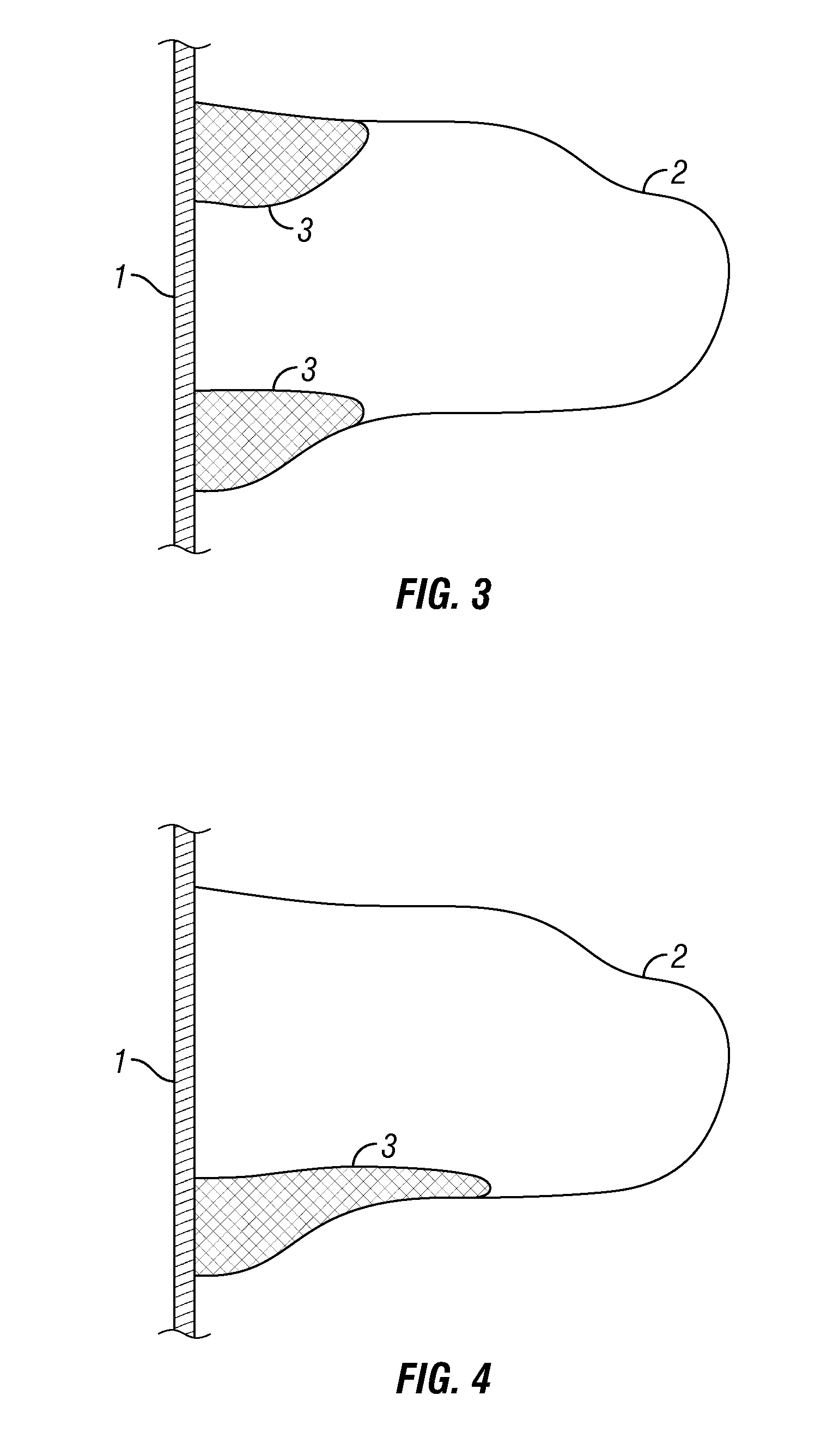

[0052]The next example illustrates the effect of the rheology of the fluid injected before the slug on the final pattern inside the fracture. In this case, the pad fluid used was a highly-viscous cross-linked gel. As a result, two barriers were placed, one at the bottom and one at the top of the fracture. The lower-viscosity fluid fingered into the higher-viscosity fluid according to the Saffman-Taylor instability and cut the barrier particle slug into uneven parts; the larger portion was displaced and then settled towards the bottom and the smaller portion was pushed towards the top. The particles used in this simulation had a mean diameter equal to 0.661 mm and a density of 2540 kg / m3. The results calculated for the particle concentration distribution are summarized in FIG. 9, and the pumping schedule is presented in Table 3.

TABLE 3Treatment schedule for Example 3PumpFluidPar-Par-Slurryrate,Vol-ticleticleVol-Pumpm3 / ume,Par-Conc.,Mass,ume,Time,StageminFluidm3ticleskg / m3kgm3min16.36...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com