Salt coating liquid and application thereof in reconstituted tobacco

A technology for reconstituting tobacco leaves and coating liquid, applied in the application, tobacco, preparation of tobacco and other directions, can solve the problems such as the inability to evenly tile the surface of the sheet in large quantities, the product quality and texture are not fluffy and soft, the moisturizing performance is poor, etc. The effect of moisturizing performance, reducing tobacco gas and improving porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

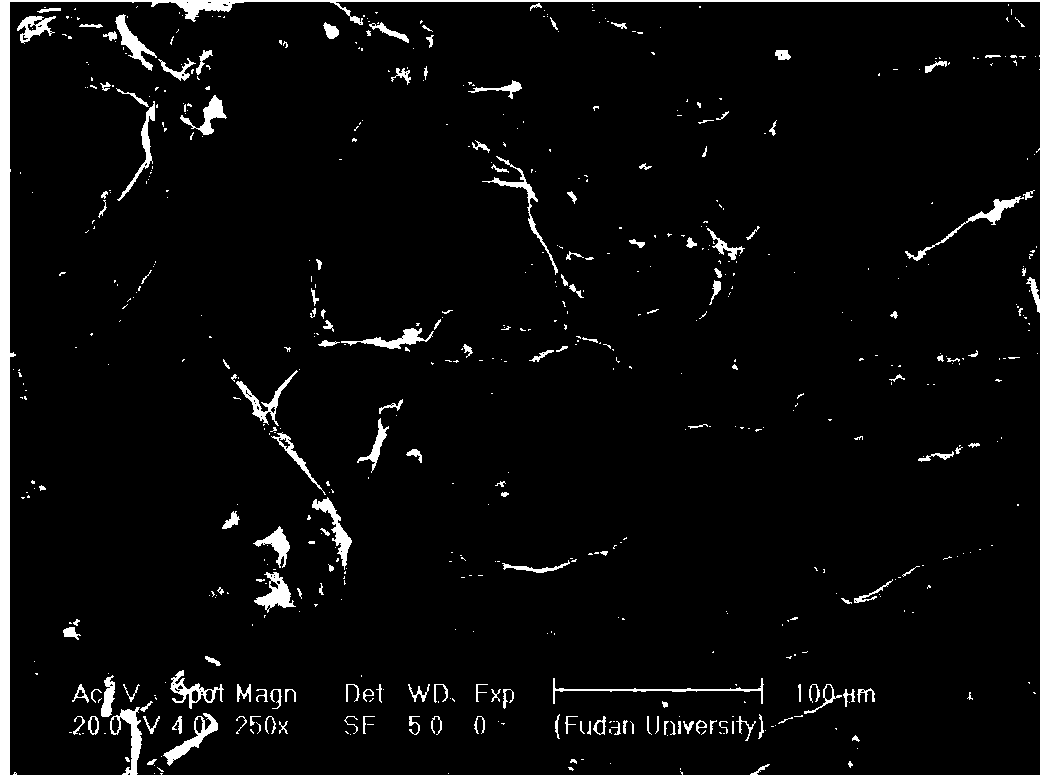

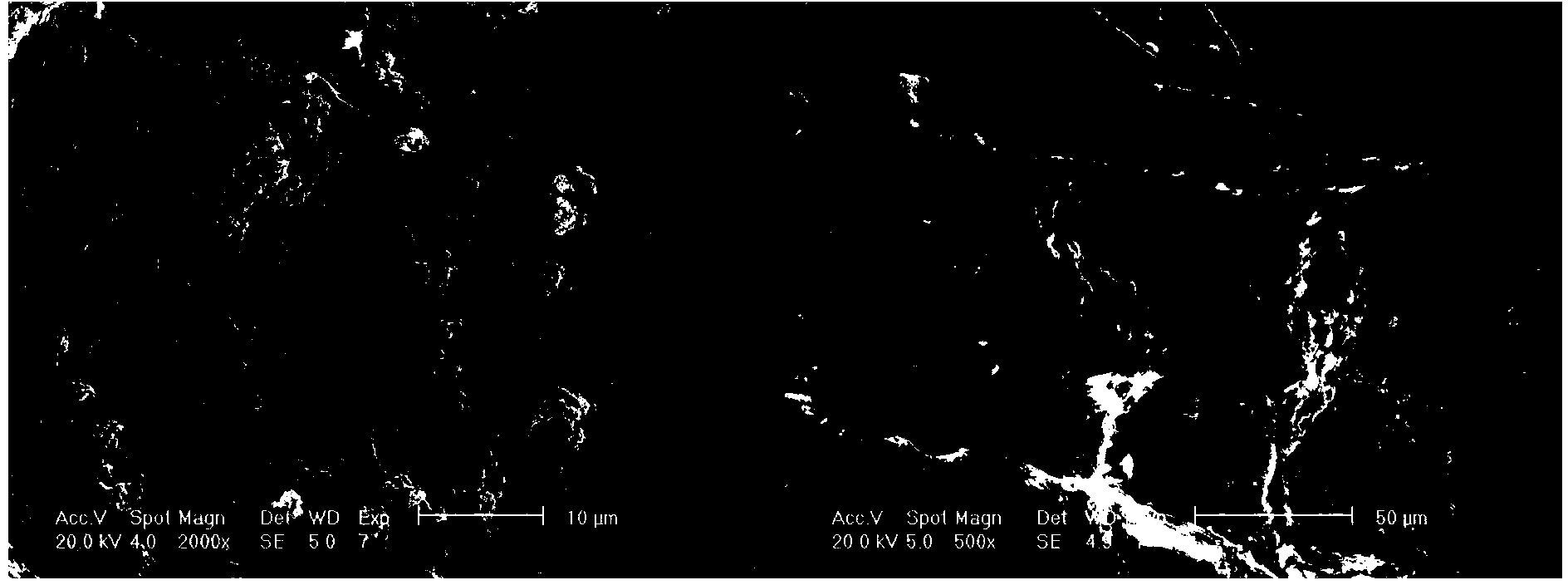

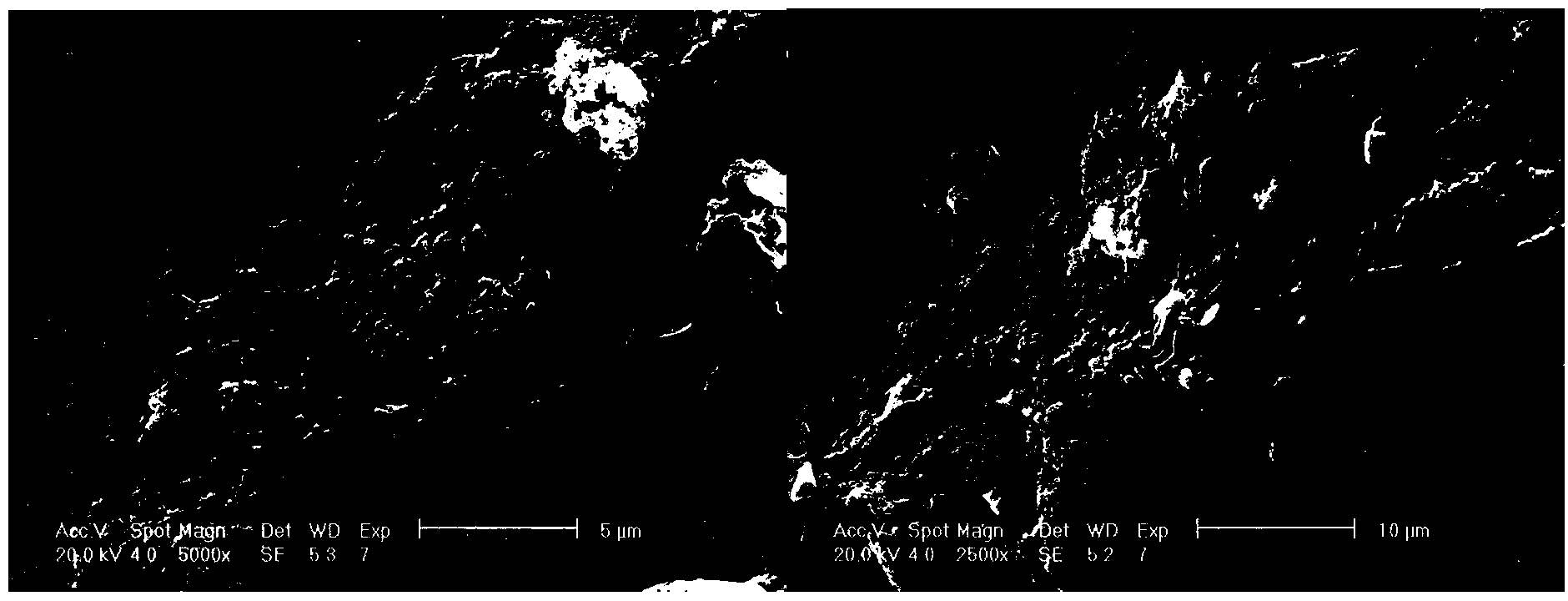

Image

Examples

Embodiment 1

[0047] The preparation method of tobacco coating liquid in the present embodiment:

[0048] The preparation method of tobacco coating liquid in the present embodiment: take the raw material of 100g papermaking method to produce tobacco flakes in the ratio of tobacco leaf fragments in weight ratio: tobacco powder: tobacco stem=4:6-6:4, add in hot water , soaked at 60-70°C for 20-60min, wherein the raw material for producing tobacco flakes: the weight ratio of hot water is 1:5-1:7; after extraction, solid-liquid separation, the obtained soluble extract; this soluble extract After further concentration, a tobacco extract concentrate with a liquid density of 1.190-1.210 kg / m3 is obtained. The insoluble matter obtained after solid-liquid separation is refined, and 8-12% of wood fiber pulp with a beating degree of 27-37°SR is added and mixed to form a mixed pulp. The beating concentration of the mixed pulp is 3.0-4.0%, and the beating degree 35-45°SR, the mixed pulp enters the pape...

Embodiment 2

[0055] The preparation method of tobacco coating liquid in the present embodiment:

[0056] The preparation method of tobacco coating liquid in the present embodiment: take the raw material of 100g papermaking method to produce tobacco flakes in the ratio of tobacco leaf fragments in weight ratio: tobacco powder: tobacco stem=4:6-6:4, add in hot water , soaked at 60-70°C for 20-60min, wherein the raw material for producing tobacco flakes: the weight ratio of hot water is 1:5-1:7; after extraction, solid-liquid separation, the obtained soluble extract; this soluble extract After further concentration, a tobacco extract concentrate with a liquid density of 1.190-1.210 kg / m3 is obtained. The insoluble matter obtained after solid-liquid separation is refined, and 8-12% of wood fiber pulp with a beating degree of 27-37°SR is added and mixed to form a mixed pulp. The beating concentration of the mixed pulp is 3.0-4.0%, and the beating degree 35-45°SR, the mixed pulp enters the pape...

Embodiment 3

[0063] The preparation method of tobacco coating liquid in the present embodiment:

[0064] The preparation method of tobacco coating liquid in the present embodiment: take the raw material of 100g papermaking method to produce tobacco flakes in the ratio of tobacco leaf fragments in weight ratio: tobacco powder: tobacco stem=4:6-6:4, add in hot water , soaked at 60-70°C for 20-60min, wherein the raw material for producing tobacco flakes: the weight ratio of hot water is 1:5-1:7; after extraction, solid-liquid separation, the obtained soluble extract; this soluble extract After further concentration, a tobacco extract concentrate with a liquid density of 1.190-1.210 kg / m3 is obtained. The insoluble matter obtained after solid-liquid separation is refined, and 8-12% of wood fiber pulp with a beating degree of 27-37°SR is added and mixed to form a mixed pulp. The beating concentration of the mixed pulp is 3.0-4.0%, and the beating degree 35-45°SR, the mixed pulp enters the pape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com