Multistage cusped magnetic field plasma thruster segmented ceramic channel

A tangential magnetic field and plasma technology, applied in the field of ion propulsion, can solve the problems of high temperature on the wall surface of the ceramic channel, large plume divergence angle, and low ionization rate, so as to avoid excessive temperature, reduce end surface corrosion, and reduce The effect of oscillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

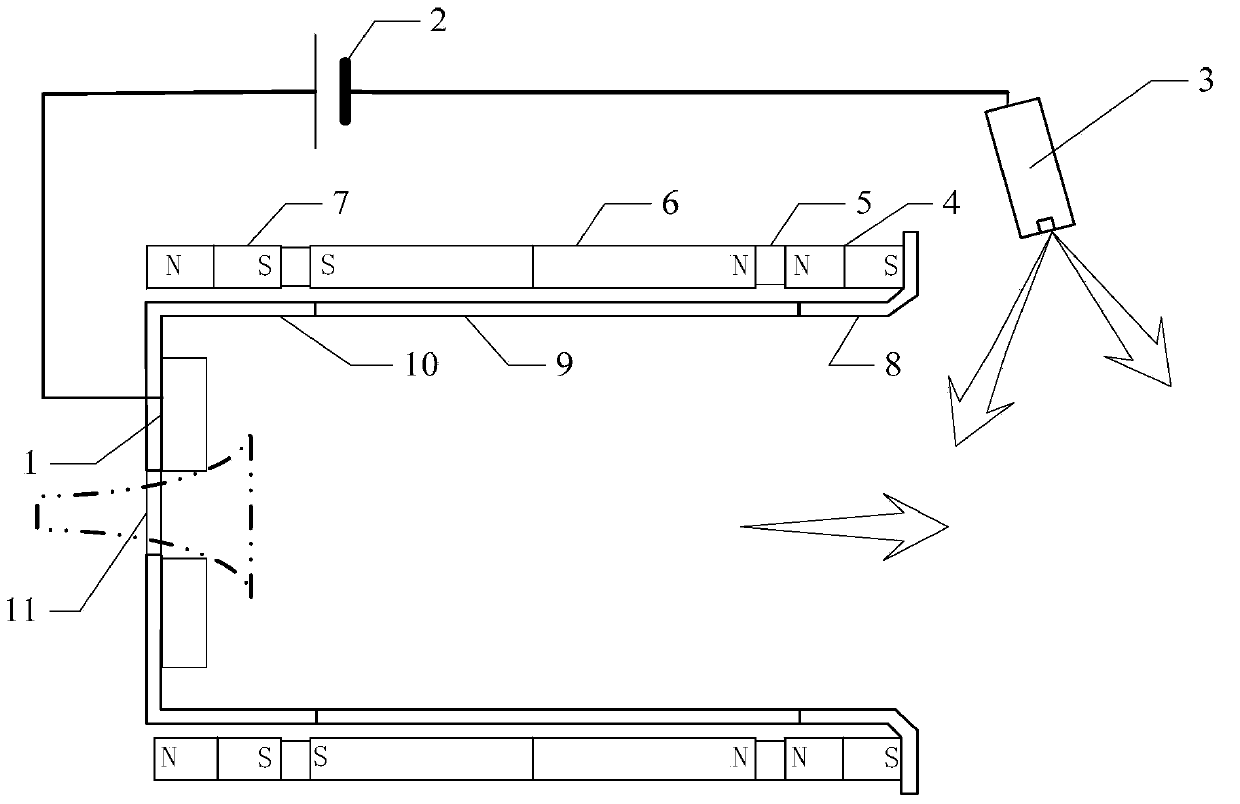

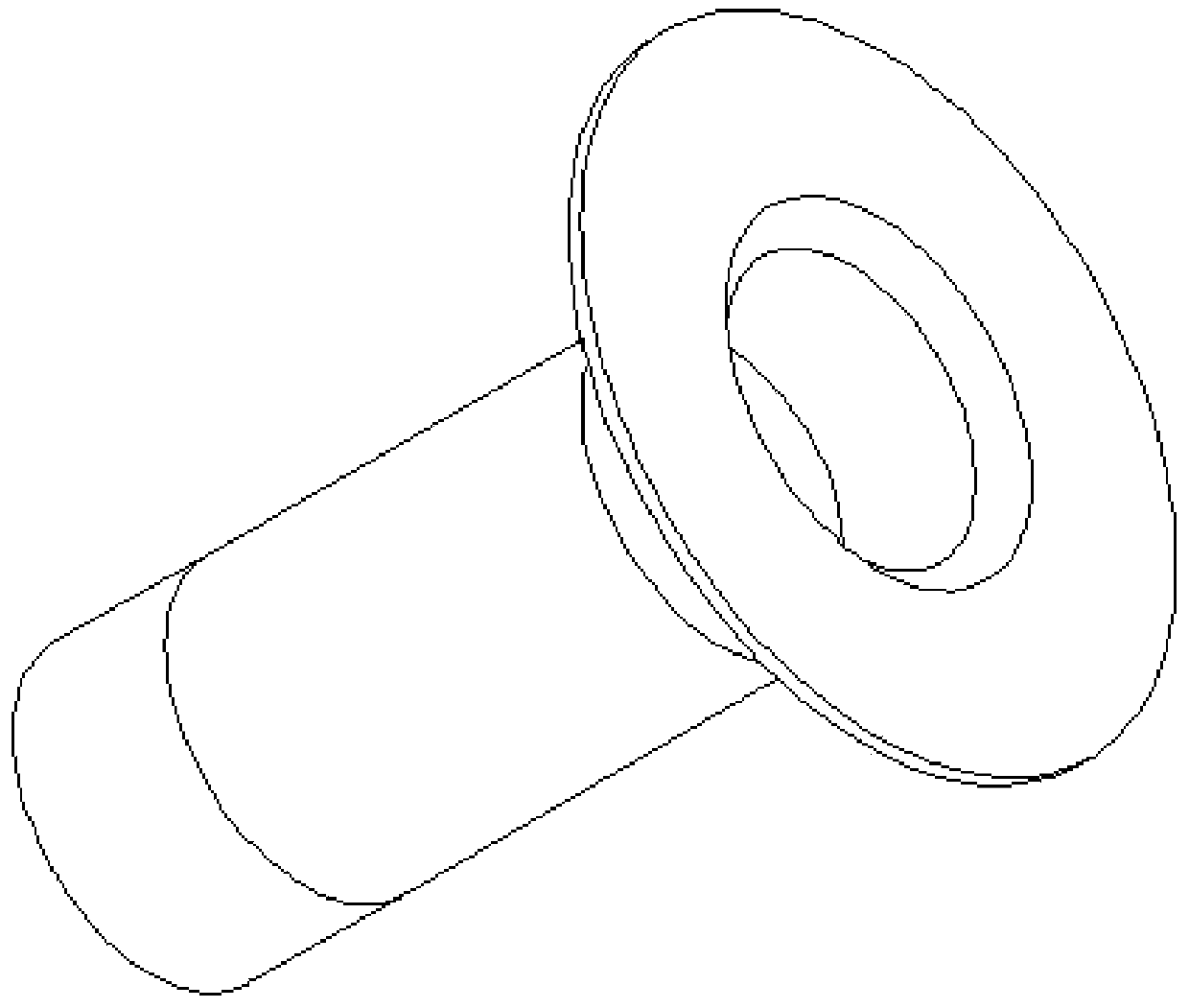

[0021] Specific implementation mode one: the following combination Figure 1 to Figure 4 Describe this embodiment, the segmented ceramic channel of the multi-stage tip tangent magnetic field plasma thruster described in this embodiment, which includes a discharge circuit and a segmented ceramic pipeline;

[0022] The discharge circuit includes an anode 1, a power supply 2 and a hollow cathode 3, the connection terminal of the hollow cathode 3 is connected to the negative terminal of the power supply 2, and the connection terminal of the anode 1 is connected to the positive terminal of the power supply 2;

[0023] Segmented ceramic pipes include basic magnetic fields and ceramic channels;

[0024] Described basic magnetic field comprises the first permanent magnet 4, two permeable rings 5, the second permanent magnet 6 and the 3rd permanent magnet 7, passes between the N extreme of the first permanent magnet 4 and the N extreme of the second permanent magnet 6 A magnetic condu...

specific Embodiment approach 2

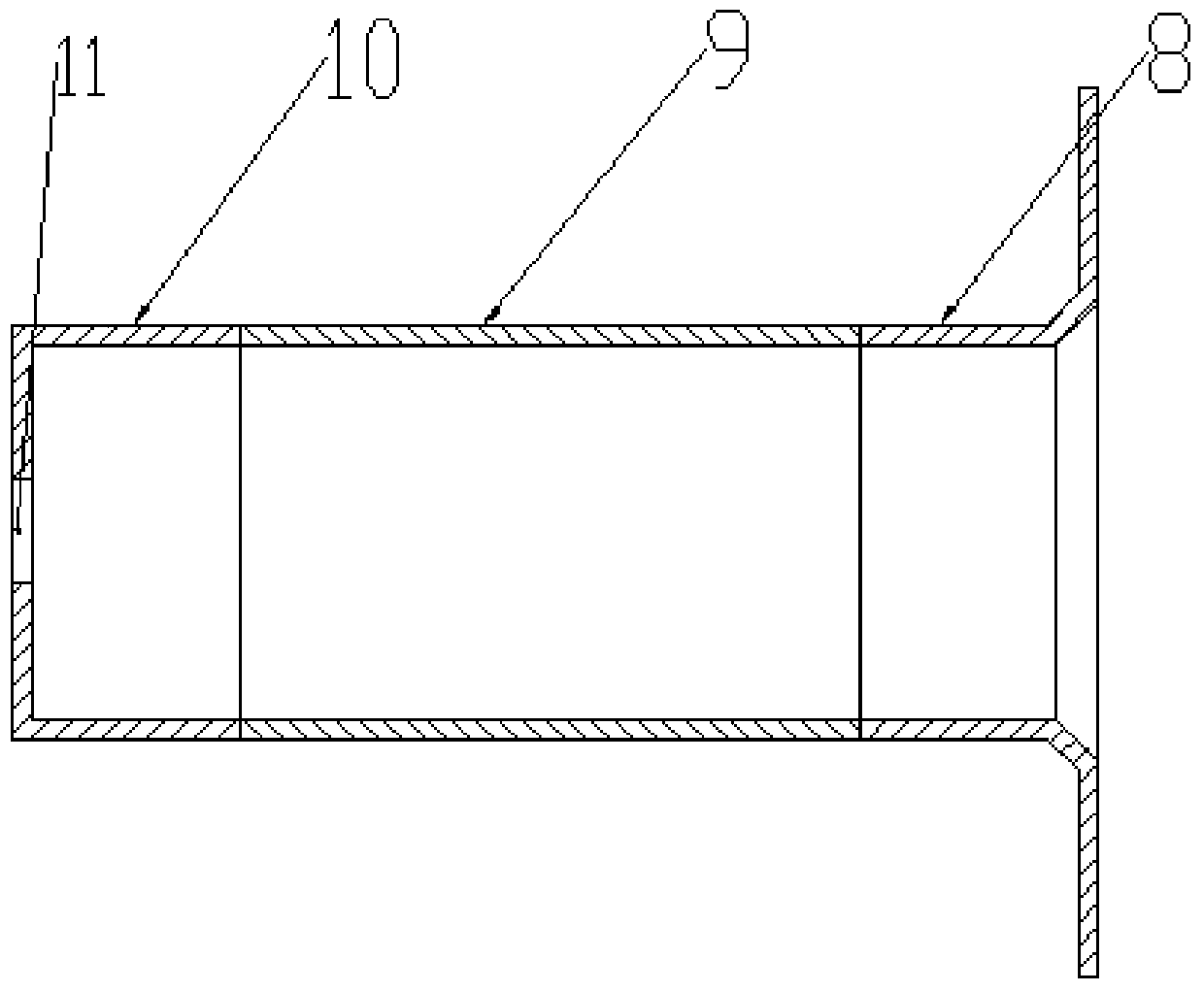

[0028] Embodiment 2: This embodiment further defines the segmented ceramic channel of the multi-stage tip tangent magnetic field plasma thruster described in Embodiment 1. In this embodiment, the ceramic baffle 8 is made of magnesium oxide material. become.

specific Embodiment approach 3

[0029] Embodiment 3: This embodiment further defines the segmented ceramic channel of the multi-stage pointed tangential magnetic field plasma thruster described in Embodiment 1. In this embodiment, the first ceramic cylinder 9 is boron nitride material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com