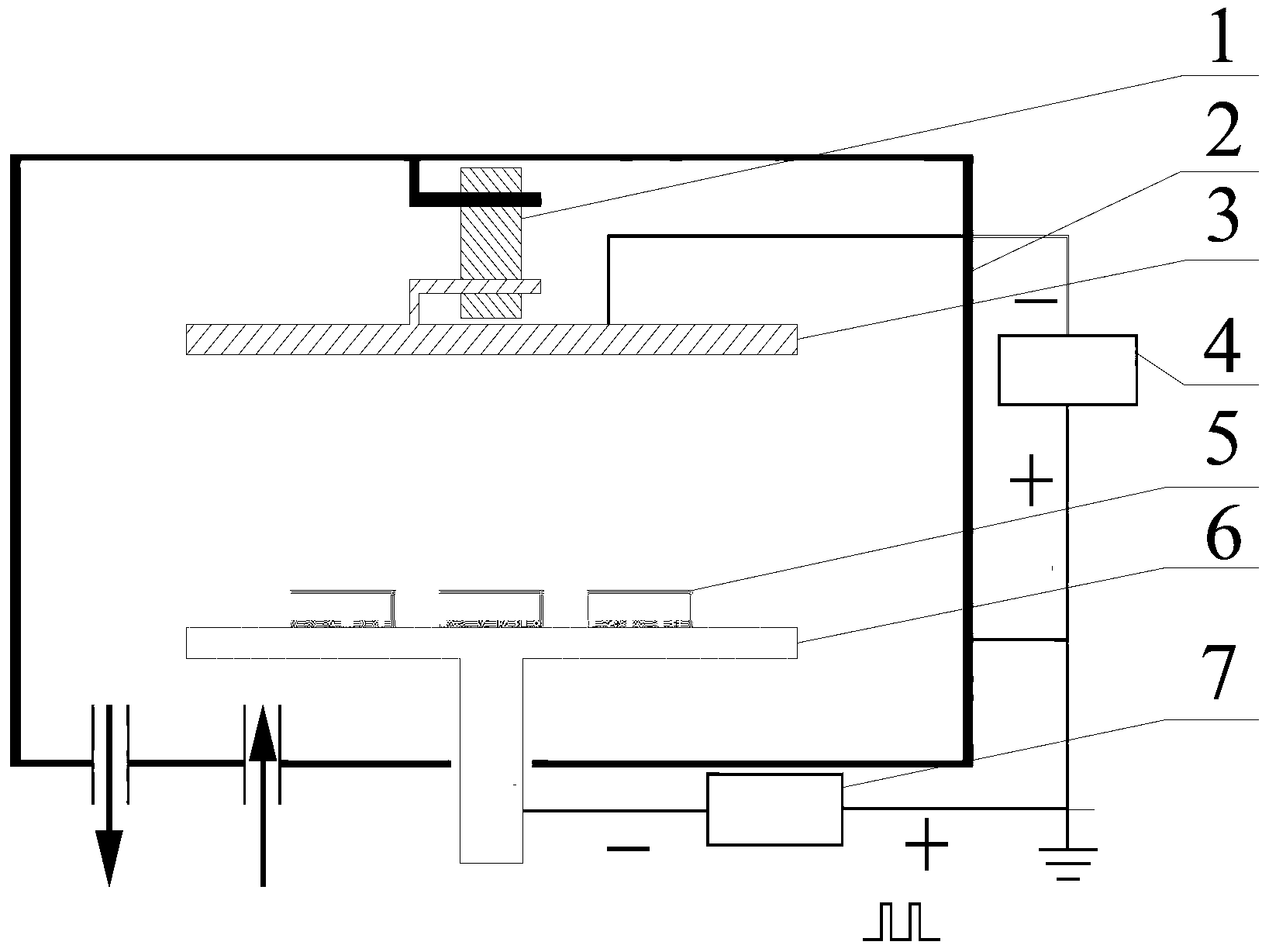

Low-temperature and low-pressure ion nitriding method and device for stainless steel workpiece

A technology of ion nitriding, low temperature and low pressure, which is applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problems of poor corrosion resistance and achieve increased nitriding efficiency, high corrosion resistance, and increased The effect of ionization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

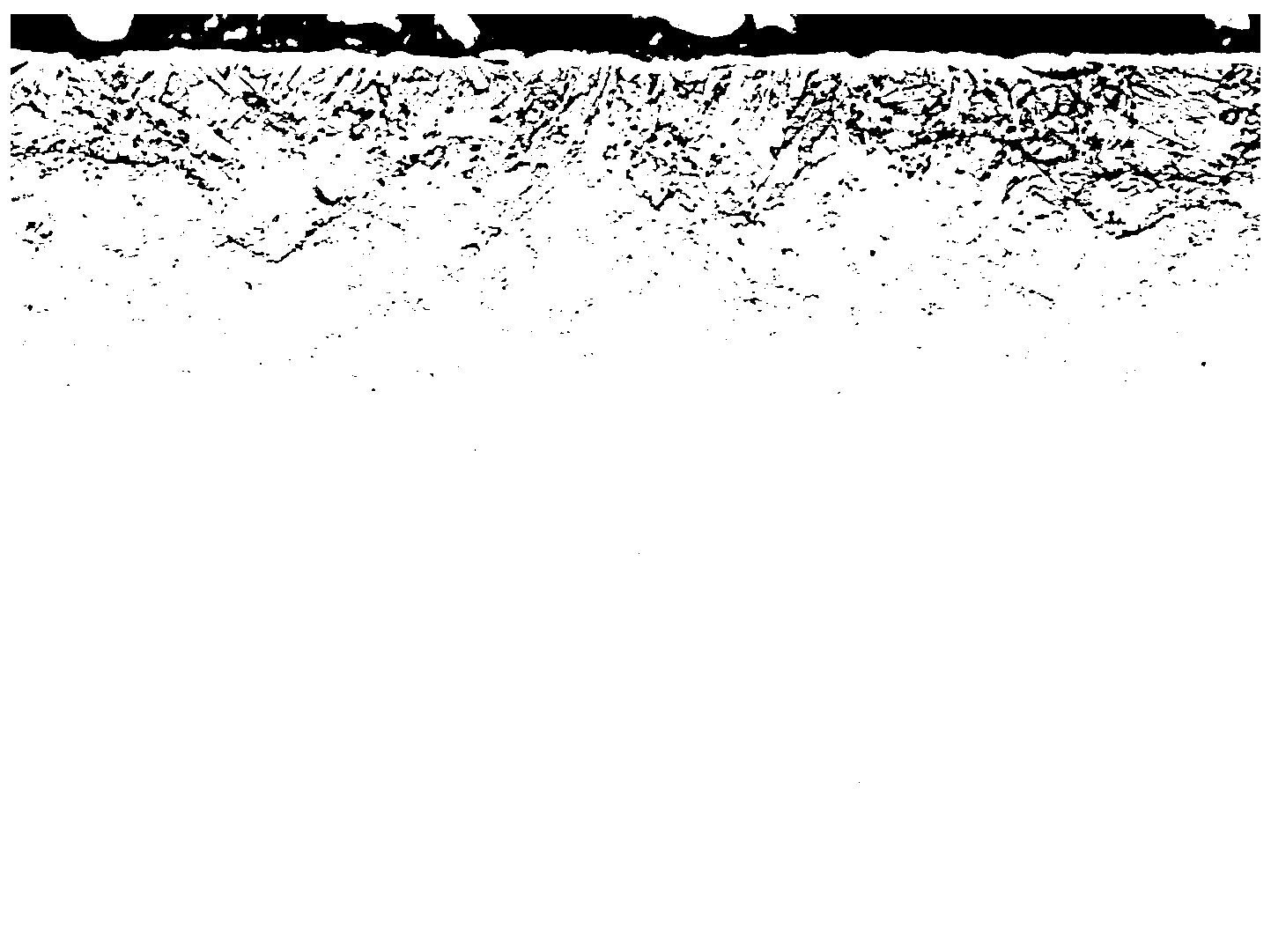

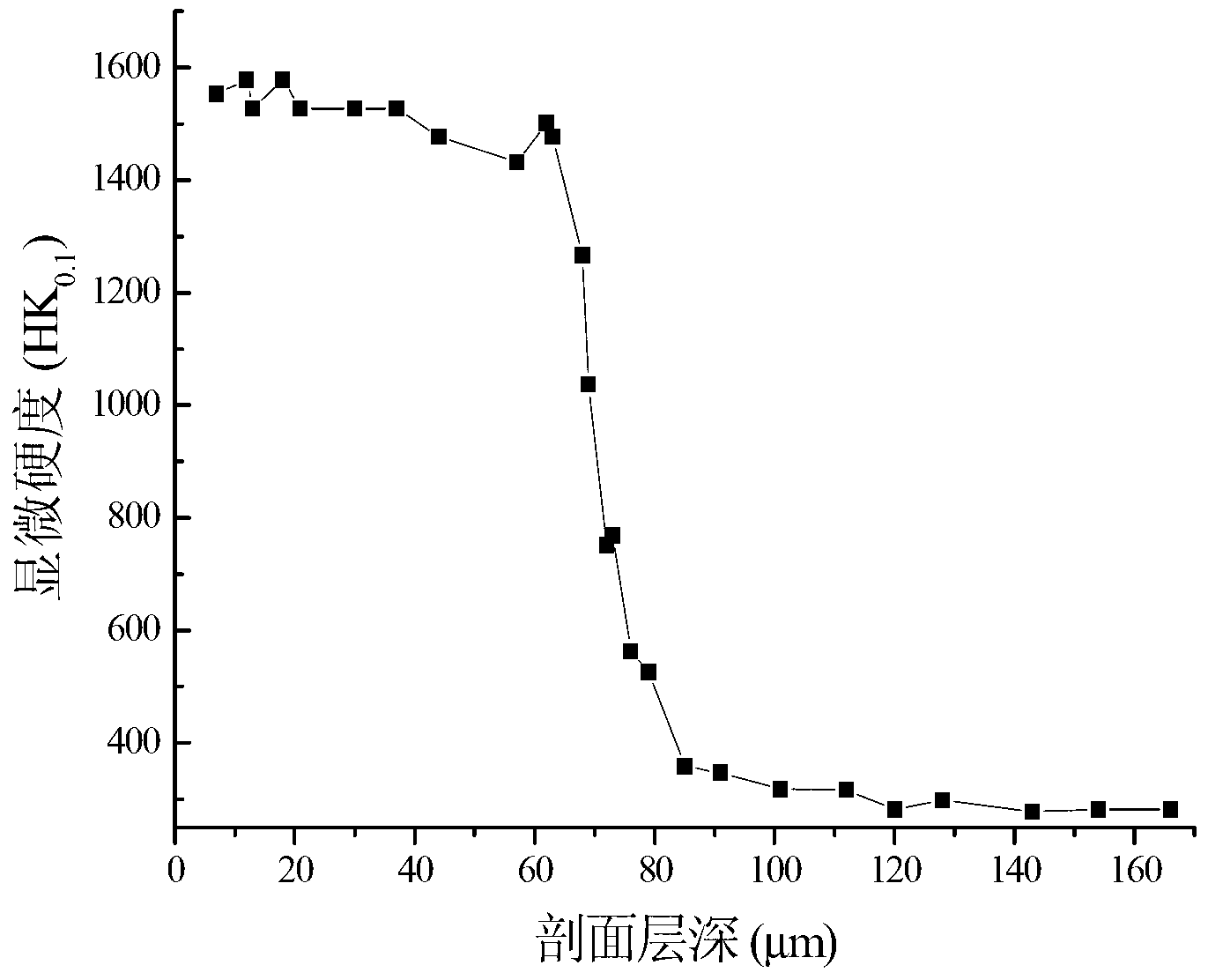

[0035] This embodiment is a low-temperature and low-pressure ion nitriding method for stainless steel workpieces. The stainless steel to be processed is AISI420 martensitic stainless steel, with a size of Φ30×12 disc and Φ12×80 rotating bending fatigue round bar workpiece. The specific operation steps are:

[0036]Step 1. Pretreatment of the workpiece surface. The surface pretreatment of the workpiece includes mechanical pretreatment of the workpiece surface, degreasing and ultrasonic cleaning of the workpiece surface. The specific process is: sequentially use 240#, 400#, 800#, 1200# water abrasive paper to polish the workpiece until it is bright, remove the burrs and impurities on the surface of the workpiece, and reduce the surface roughness of the workpiece. Degrease the ground workpiece with an aqueous solution of a commercial alkaline degreaser. The degreasing time is 5 minutes, and the temperature is 40°C. Tap water was used to rinse the workpiece surface. The ultras...

Embodiment 2

[0043] This embodiment is a low-temperature and low-pressure ion nitriding method for stainless steel workpieces. The stainless steel to be processed is 17-4PH martensitic stainless steel, with a size of Φ30×12 discs and Φ12×80 rotating bending fatigue round rod workpieces. The specific operation steps are:

[0044] Step 1. Pretreatment of the workpiece surface. The surface pretreatment of the workpiece includes mechanical pretreatment of the workpiece surface, degreasing and ultrasonic cleaning of the workpiece surface. The specific process is: sequentially use 240#, 400#, 800#, 1200# water abrasive paper to polish the workpiece until it is bright, remove the burrs and impurities on the surface of the workpiece, and reduce the surface roughness of the workpiece. When removing oil, first carry out alkali cleaning on the polished workpiece. Degrease the ground workpiece with an aqueous solution of a commercial alkaline degreaser. The degreasing time is 5 minutes, and the tem...

Embodiment 3

[0050] This embodiment is a low-temperature and low-pressure ion nitriding method for stainless steel workpieces. The stainless steel to be processed is AISI420 martensitic stainless steel, with a size of Φ30×12 disc and Φ12×80 rotating bending fatigue round bar workpiece. The specific operation steps are:

[0051] Step 1. Pretreatment of the workpiece surface. The surface pretreatment of the workpiece includes mechanical pretreatment of the workpiece surface, degreasing and ultrasonic cleaning of the workpiece surface. The specific process is: sequentially use 240#, 400#, 800#, 1200# water abrasive paper to polish the workpiece until it is bright, remove the burrs and impurities on the surface of the workpiece, and reduce the surface roughness of the workpiece. When removing oil, first carry out alkali cleaning on the polished workpiece. Degrease the ground workpiece with an aqueous solution of a commercial alkaline degreaser. The degreasing time is 5 minutes, and the temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com