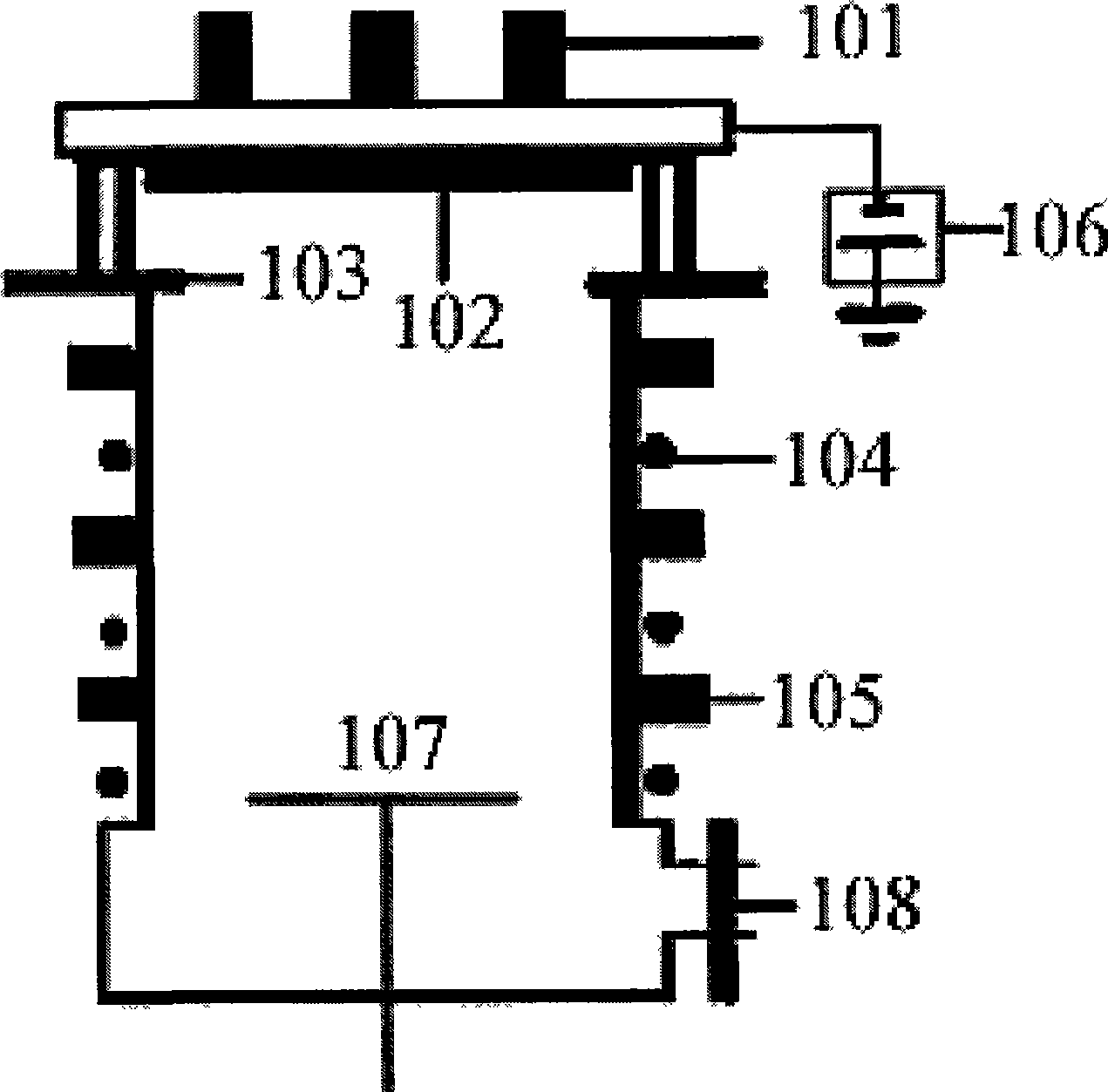

Non-balance magnetron sputtering thin film deposition apparatus for cusped magnetic field confined ICP reinforced ionization

A thin film deposition device and magnetron sputtering technology, which are applied in sputtering coating, ion implantation coating, metal material coating process, etc. The uniformity of volume space distribution and limited improvement can achieve the effect of reducing diffusion loss, reducing radiation damage and improving uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] Select argon (purity 99.999%) as the working gas, and the working pressure is 1.5×10 -1 Pa, the sputtering target is a copper target.

[0021] 1. Install the sputtering copper target, close the vacuum chamber, and start vacuuming to 3×10 -3 Pa.

[0022] 2. Start the magnetron sputtering discharge. When the applied magnetron sputtering voltage is greater than 300V, the gas will be broken down to form a magnetron sputtering discharge. The DC discharge current can reach 200mA. Execute for a period of time to make the discharge stable.

[0023] 3. Open the vacuum chamber, place the cleaned monocrystalline silicon with a size of 20×20 mm on the sample stage, close the vacuum chamber, and start vacuuming to 3×10 -3 Pa, then pass argon to a vacuum of 1.5×10 -1 Pa.

[0024] 4. Turn on the ICP discharge to make the RF input power reach 200W.

[0025] 5. Apply a pulse bias voltage on the sample stage, the pulse peak voltage is 1500V, the pulse frequency is 1.0kHz, the duty r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic field | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com