Desk type annular block abrasion and wear tester

A friction and wear test, ring block technology, applied in the direction of instruments, wear resistance testing, measuring devices, etc., can solve the defects of not considering the utilization rate of sample material and test efficiency, the utilization rate of sample material and test efficiency, and not considering Test block utilization rate and test efficiency and other issues, to improve test performance, compact structure, easy loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

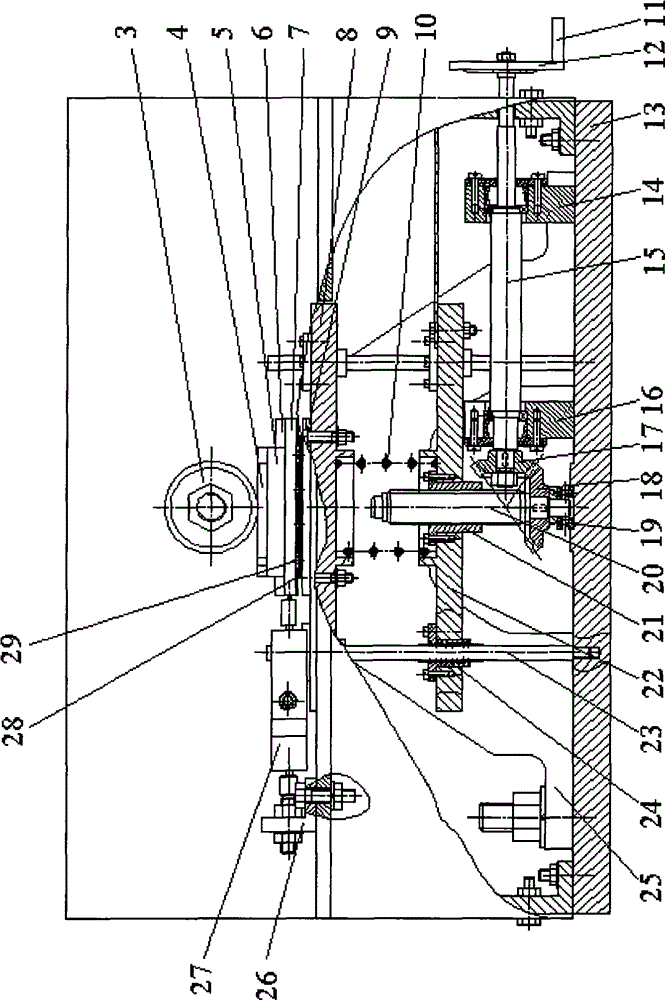

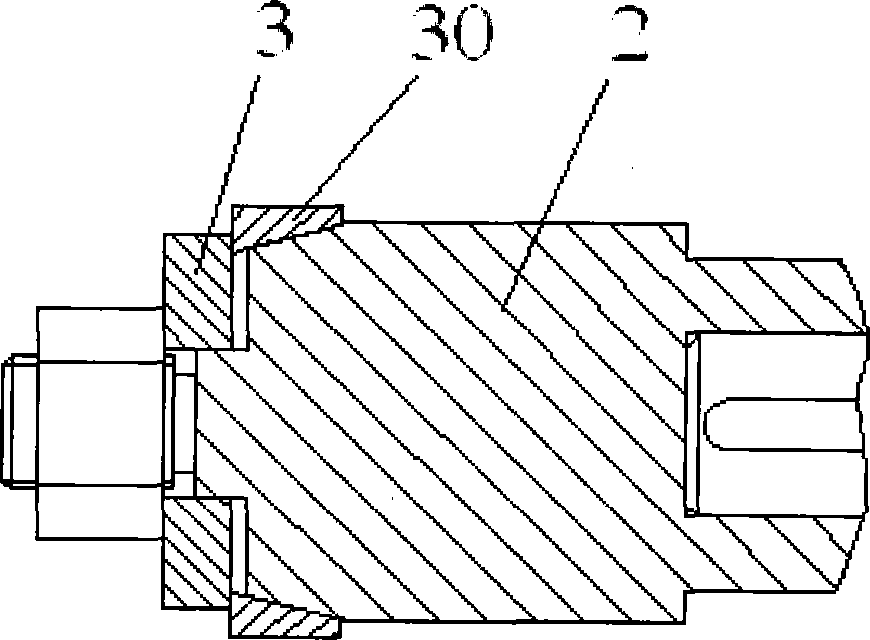

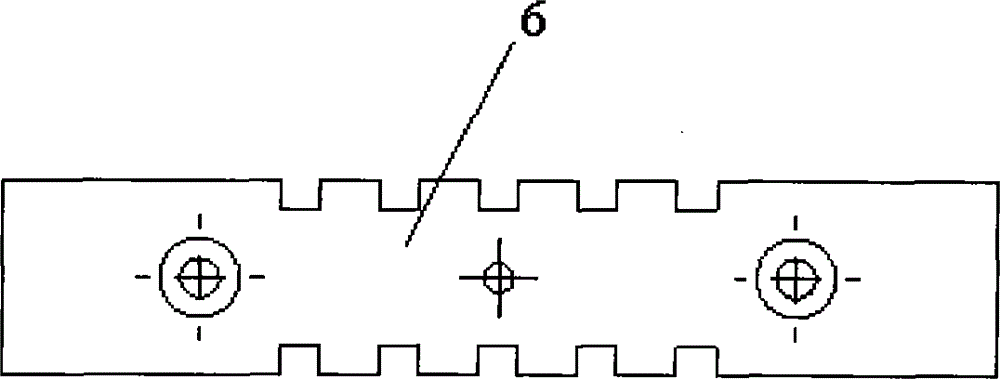

[0027] like figure 1 and Figure 4 As shown, a bench-top ring block friction and wear tester consists of a loading part, a driving part, a testing part and a measuring part. The loading part includes a base 13, an optical shaft 23, a spring support plate 22, a fixture support seat 8, a first support 14, a second support 16, a transmission shaft 15, a first bevel gear 17, a handle 11, a hand wheel 12, Thrust bearing 19, lead screw 20, nut 21, second bevel gear 18, spring, their installation, connection relation are as follows: base 13 is vertically provided with a plurality of optical shafts 23, and the middle section of a plurality of optical shafts 23 is equipped with springs Support plate 22, a plurality of optical shafts 23 upper segments are slidably provided with clamp support base 8, spring support plate 22, clamp support base 8 and optical axis 23 joints are respectively provided with linear rolling bearings 24 that are sleeved on the optical axis, and base 13 is also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com