Indoor simulation experiment system for pipe-jacking grouting drag reduction

A simulation experiment and grouting system technology, applied in the field of construction engineering, can solve the problems of inability to simulate grouting to reduce drag, the pipe jacking grouting test has not been found, and the jacking process cannot be simulated, and the test results are accurate and reliable, and the structure is simple. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

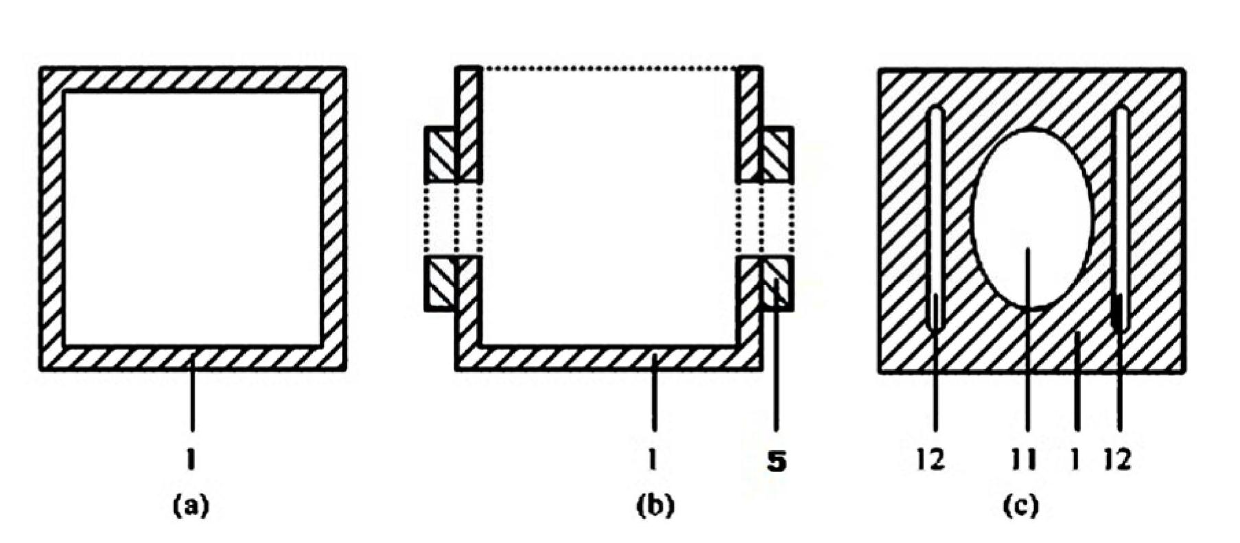

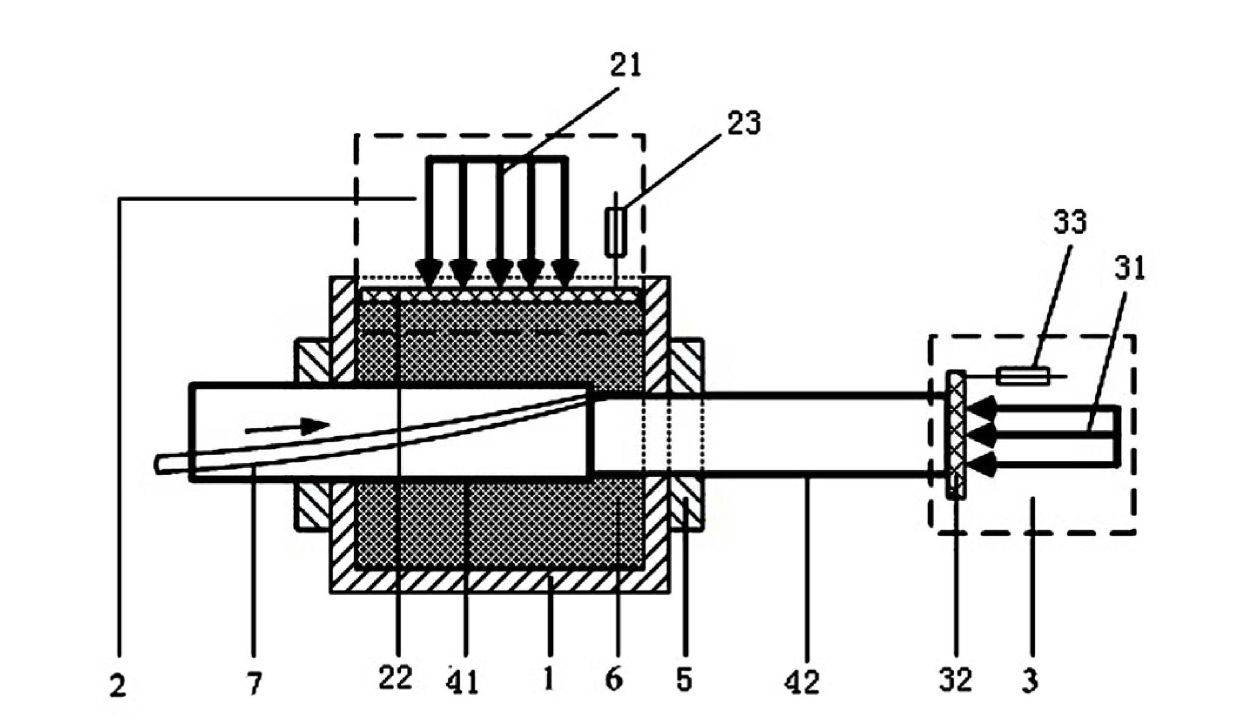

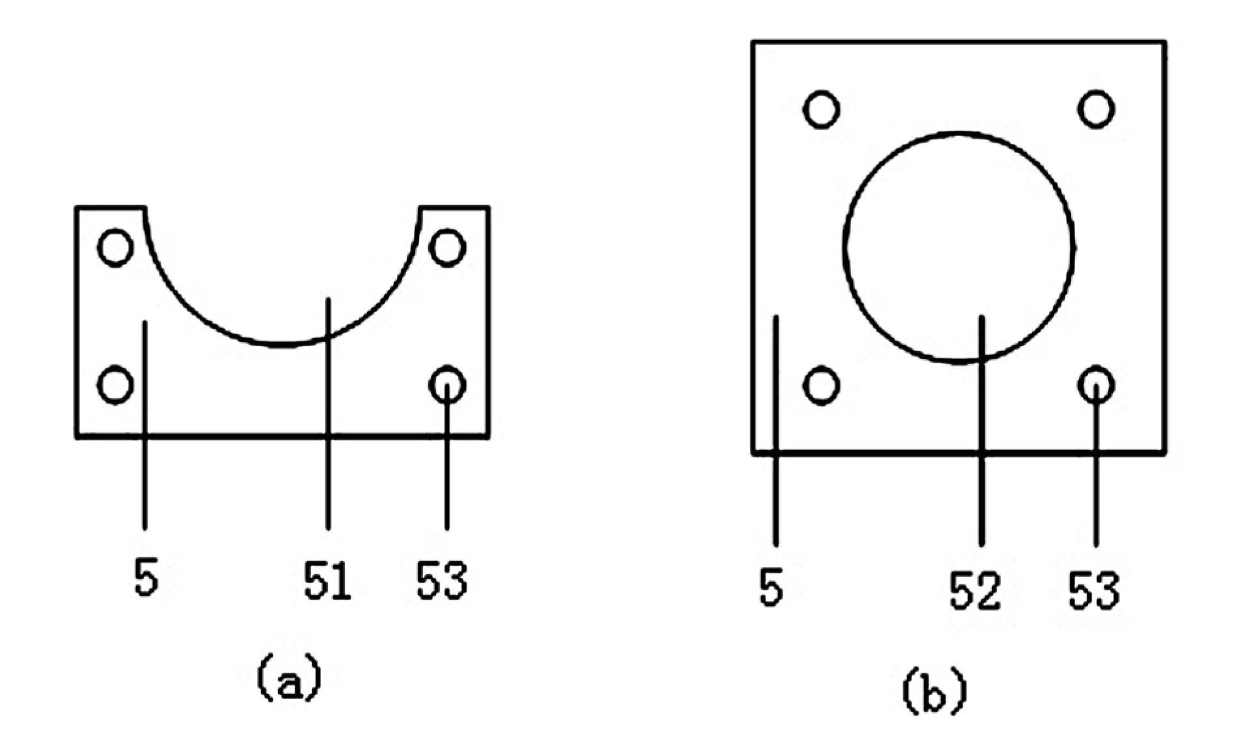

[0032] Such as figure 1 , figure 2 and Figure 4 As shown, the indoor simulation experiment system of pipe jacking grouting drag reduction in this embodiment includes a test box 1, the upper opening of the test box 1 is provided with a vertical loading test system 2, and the two opposite sides of the test box 1 are provided with An oblong hole 11, and a horizontal loading test system 3 is provided on one side thereof. A soil sample 6 is buried in the test box, and the pipeline 4 to be tested passes through the test box through the oblong holes 11 on both sides of the test box.

[0033] The indoor simulation experiment system of pipe jacking grouting drag reduction of the present embodiment also includes a grouting system 9 and a grouting conduit 7 connected with the grouting system, and the pipeline 4 to be tested is composed of a pipeline front section 41 and a pipeline rear Section 42 constitutes, and the pipe diameter of pipeline front section 41 is slightly thicker tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com