Manufacturing method of high branching degree acrylamide graft copolymer taking amylopectin as framework

A graft copolymer, amylopectin technology, applied in the field of highly branched water-soluble polymers, to achieve excellent water retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

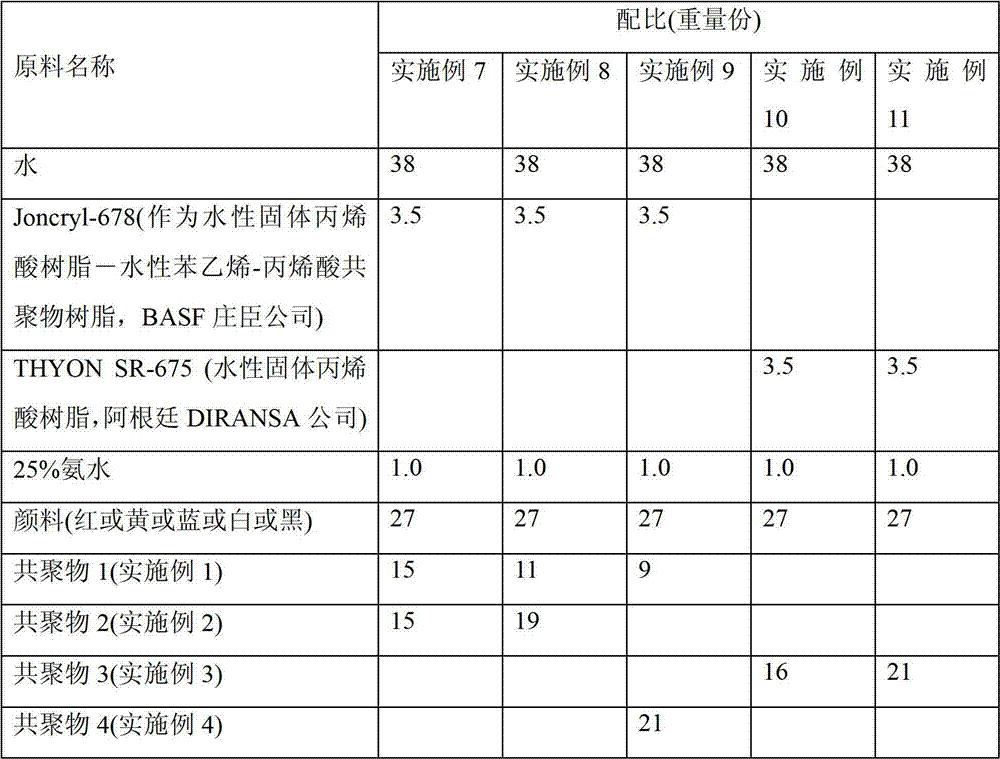

Examples

Embodiment 1

[0093] (1) Under stirring, add 330 kg of water, 30 kg of pullulan, 50 kg of acrylamide, 1 kg of urea, 1 kg of ammonium persulfate, 0.5 kg of allyloxypolyethylene oxide (12 ) nonylphenyl ether ammonium sulfate, 0.23 kg of acetoacetate ethyl methacrylate (AAEM), 0.12 kg of adipic acid dihydrazide, 0.2 kg of 5% sodium sulfite solution was added during stirring, and mixed at room temperature and normal pressure for 1.5 hours;

[0094] (2) The above-mentioned slurry is transported to a drum dryer through a pipeline, and a highly branched pullulan acrylamide copolymer (referred to as copolymer 1) is obtained through slurry distribution, reaction, and drying.

[0095] (3) Measure the product with NDJ-1 viscometer, the viscosity of 2% aqueous solution is 18000cp.

[0096] Note: AAEM: ketone carbonyl-containing cross-linking monomer, ethyl methacrylate acetoacetate, English name: acetoacetoxyethyl methacrylate.

[0097] Characterization of mild cross-linking: due to the relatively co...

reference example 1

[0099] Example 1 was repeated except that the cross-linker adipic dihydrazide was not used. Product viscosity: 5500cp. The viscosity of the product of Comparative Example 1 is about 1 / 3 of the viscosity of the product in Example 1, indicating that Reference Example 1 does not crosslink, but Example 1 crosslinks because of the crosslinking agent, because it is still soluble in water, so it is judged to be slightly cross-linked.

Embodiment 2-6

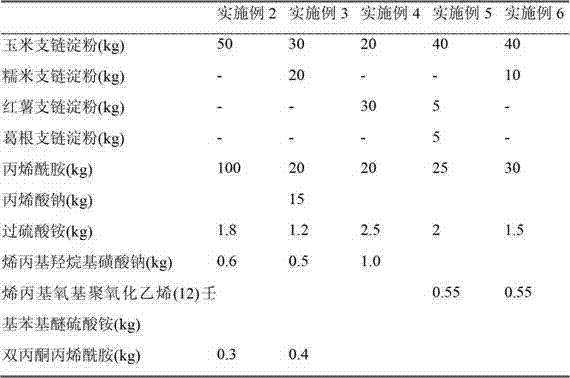

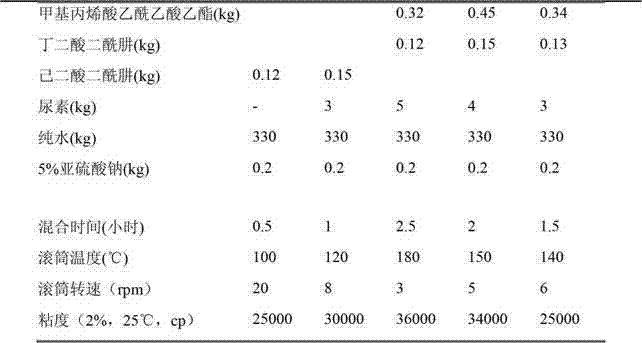

[0100] Embodiment 2-6: The basic operation process is the same as that of Embodiment 1, and the ratio of materials is shown in Table 1 below (the amount of components is in kg).

[0101]

[0102]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com