High conductivity flexible aluminum wire and manufacturing method thereof

A technology with high conductivity and manufacturing methods, which is applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of increased investment and construction costs of transmission line projects, incomplete resistivity of alloy ingots, and unreachable conductivity. Achieve huge economic and social benefits, low resistivity, and increase the effect of carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

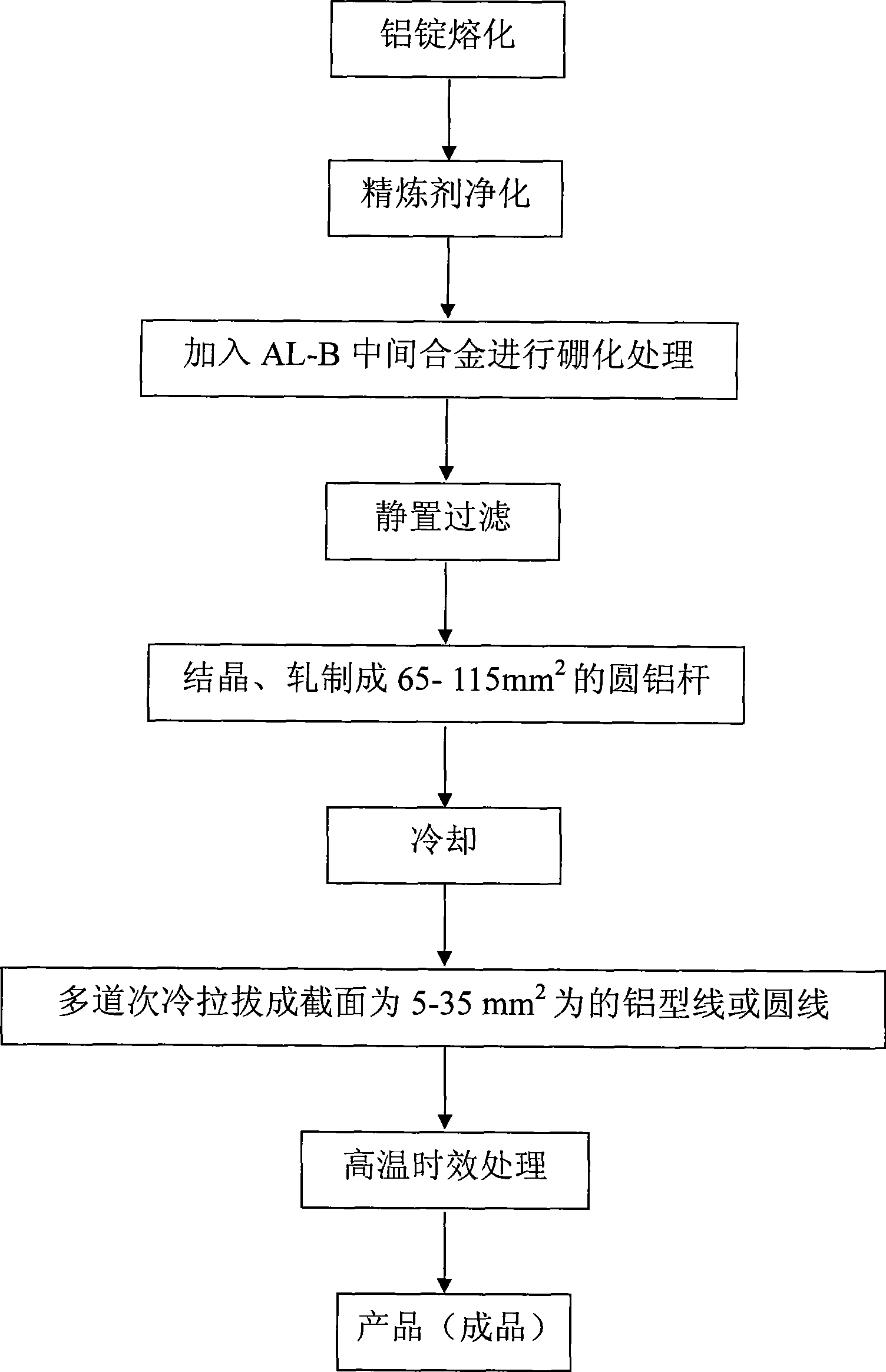

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: 10 tons of aluminum ingots of 99.80 grades are used for melting, and a spectrophotometer is used to analyze that the Si content in the molten aluminum is 0.05%; the Fe content is 0.13%, and the Cu content is 0.004%; nitrogen is blown at the bottom of the furnace in the holding furnace. Add 30kg of refining agent for purification treatment, and control the temperature at 750°C; add AL-B master alloy after 10 minutes to ensure that the boron content in the molten aluminum is controlled at 0.07-0.15%, stir for 3 minutes, and let it stand for 25 minutes , Open the valve of the holding furnace, the aluminum liquid flows into the gutter, and the double-layer glass fiber filter is used to filter impurities. The filtered aluminum liquid enters the crystallization wheel to ensure that the cooling water is uniform and effective, and the ingot rolling temperature is controlled at 450°C, the emulsion temperature is controlled at 55°C during rolling, and the final rolli...

Embodiment 2

[0020] Embodiment 2: 8 tons of aluminum ingots of 99.70A grade are used for melting, and a spectrophotometer is used to analyze that the Si content in the molten aluminum is 0.07%; the Fe content is 0.16%, and the Cu content is 0.004%; nitrogen is blown into the holding furnace at the bottom of the furnace Purify 32kg of refining agent and control the temperature at 740°C; add AL-B master alloy after 10 minutes to ensure that the boron content in the molten aluminum is controlled at 0.07-0.15%, stir for 5 minutes, and let it stand for 28 minutes. Open the valve of the holding furnace, the aluminum liquid flows into the gutter, and the impurities are filtered by double-layer glass fiber filter. The filtered aluminum liquid enters the crystallization wheel to ensure that the cooling water is uniform and effective, and the ingot rolling temperature is controlled at 460°C, the emulsion temperature is controlled at 60°C during rolling, and the final rolling temperature of the measur...

Embodiment 3

[0021] Example 3: 4 tons of 99.70A and 6 tons of 99.80 brand aluminum ingots are used for melting, and the Si content in the molten aluminum is analyzed by a spectrophotometer to be 0.06%; the Fe content is 0.15%, and the Cu content is 0.003%; nitrogen is used in the holding furnace 40kg of molten aluminum refining agent is blown into the bottom of the furnace for purification treatment, and the temperature is controlled at 730°C; after 10 minutes, AL-B master alloy is added, and the amount of AL-B master alloy added should ensure that the boron content in the aluminum liquid is controlled Stir for 5 minutes at 0.07-0.15%, after standing still for 25-30 minutes, open the valve of the holding furnace, the aluminum liquid flows into the gutter, and filter the impurities with a double-layer glass fiber filter. The filtered aluminum liquid enters the crystallization wheel to ensure that the cooling water is uniform and effective, and the ingot rolling temperature is controlled at 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com