Method for producing heat-resisting high-strength aluminium alloy wire

A technology of aluminum alloy wire and aluminum alloy, which is applied in cable/conductor manufacturing, metal rolling, rod/bar/wire/strip conductor, etc., can solve the problem of not meeting the design requirements of large-span power transmission and transformation lines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

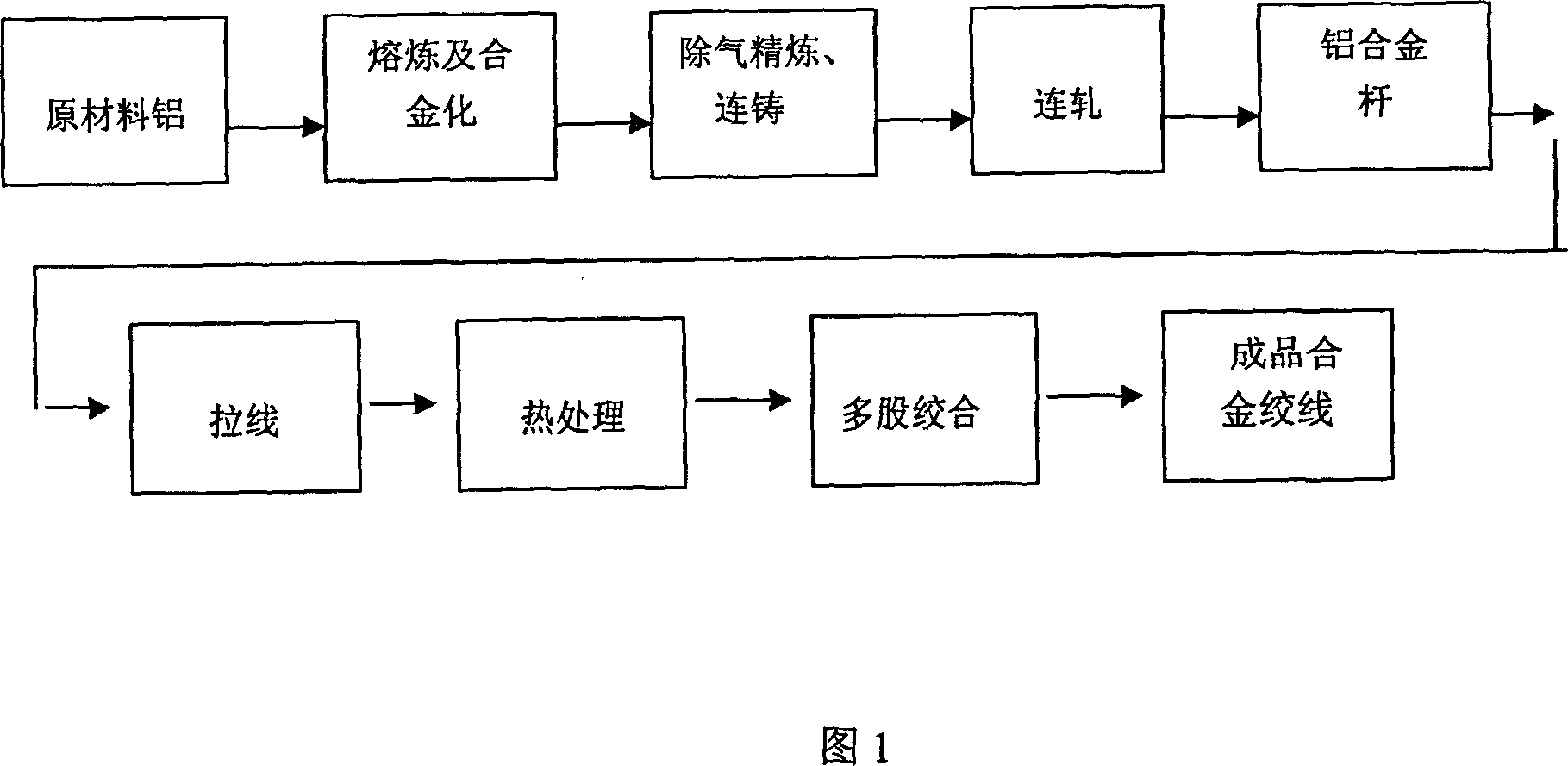

Method used

Image

Examples

Embodiment 1

[0014] Eight tons of aluminum ingots (99.7%) are selected, and the impurity content (except silicon, iron, and copper) does not exceed 0.02% by weight, and they are melted in a circular aluminum melting furnace, and 0.045 to 0.15% by weight of zirconium, 0.02 -0.12% copper, 0.2-0.95% iron, and 0.05-0.4% rare earth as alloying elements. The alloying temperature is 730-760°C, after homogenization and stirring, refining and degassing, the refining temperature of the aluminum alloy liquid is 730-760°C, slagging and slag removal, covering the surface of the aluminum alloy liquid with a solid covering agent, and standing for 35-45 Minutes; rapid analysis of the chemical composition before the furnace, monitoring and adjustment of the element content, the aluminum alloy liquid that meets the requirements passes through the launder, the continuous degassing furnace (the temperature of the aluminum alloy liquid in the continuous degassing furnace is 700-760 ° C), aluminum slag Filter b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com