Hexafluoropropyl epoxide continuous production technique

A technology of hexafluoropropylene oxide and hexafluoropropylene, which is applied in the field of preparation of fluorine-containing fine chemicals, can solve the problems of low production capacity, excessive use of personnel, and uneconomical problems, and achieve high equipment utilization, simple process flow, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

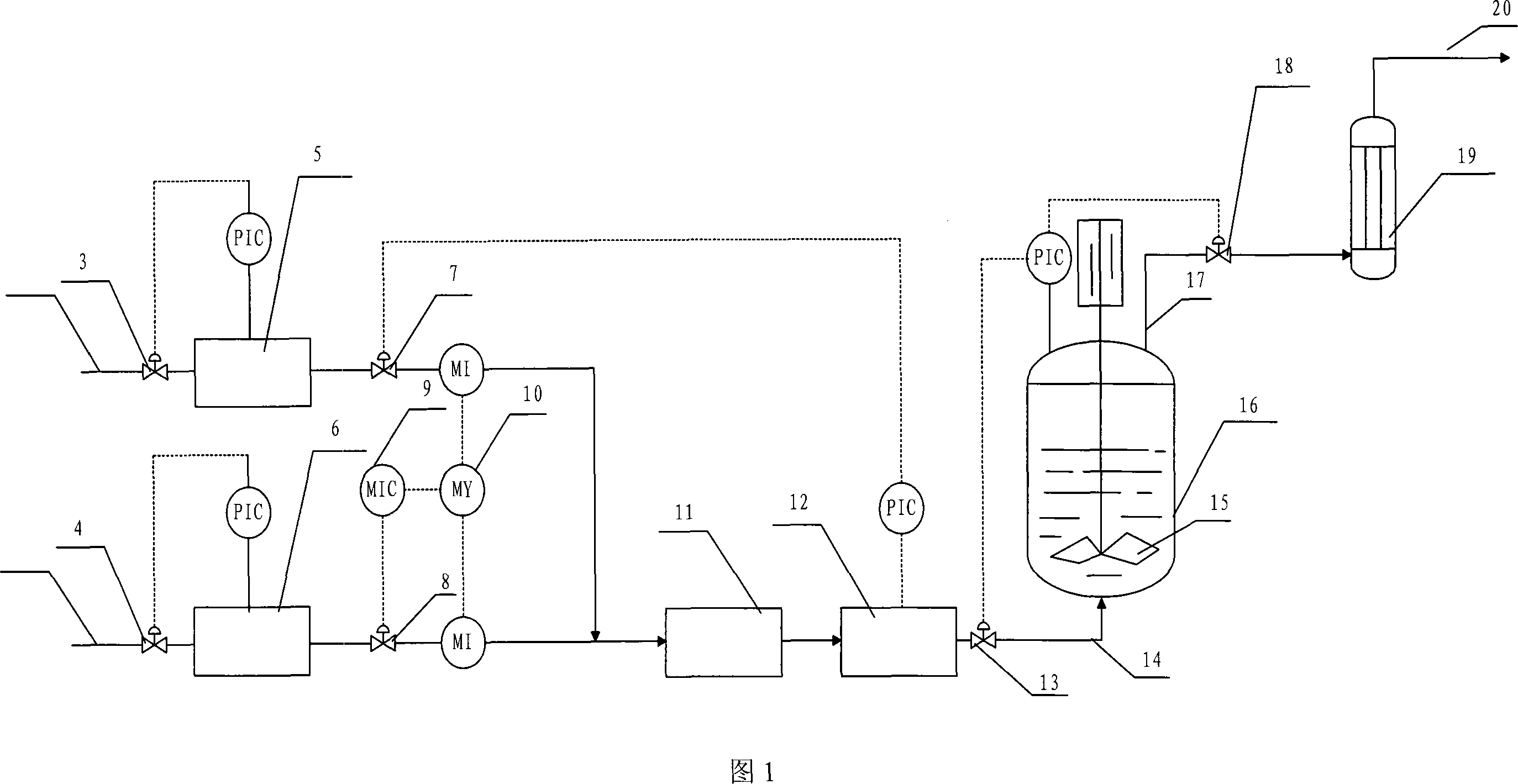

[0039] Example: A method for continuous production of hexafluoropropylene oxide, which allows hexafluoropropylene to fully react with oxygen and discharge the material at the same time, mixes hexafluoropropylene gas and oxygen in proportion, and then passes the gaseous mixture into the solvent in the reactor , Oxygen and hexafluoropropylene first pass through the solvent layer in the reactor, and fully react in the solvent. The reactants continue to accumulate in the gas phase space in the reactor. The material is discharged outside the kettle, and the discharged gas is condensed by the condenser to recover the solvent entrained in the mixed gas. The condensed reactant gas is sent to the post-processing system for further treatment and purification, and finally the required hexafluoropropylene oxide product is obtained. With reference to the continuous reaction flow chart of Fig. 1, describe in detail as follows:

[0040] The oxygen delivered by pipeline 1 and the hexafluoroprop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com