Solid catalyst and its preparation and method of catalytic preparation epoxy propane hexafluoride

A technology of hexafluoropropylene oxide and solid catalyst is applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., and can solve the problem of low conversion rate of hexafluoropropylene and industrialization. Difficulty in application, reduced selectivity of hexafluoropropylene oxide, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

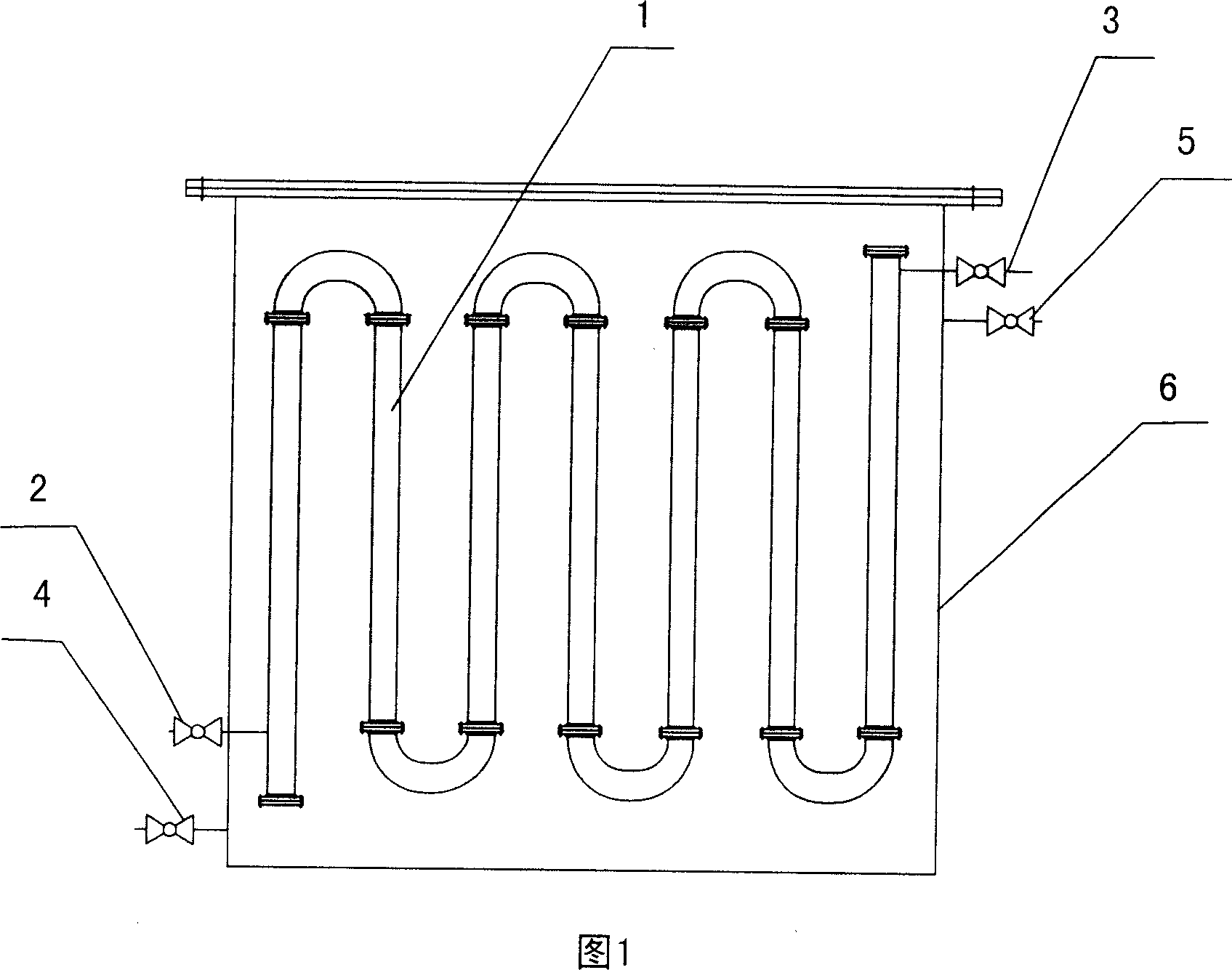

Image

Examples

Embodiment 1

[0023] Weigh 2g of oxalic acid and dissolve it in 5ml of water, then mix it with 5ml of ethylenediamine, add 3.5g of silver oxide under full stirring, and continue stirring to dissolve it to form a silver ammonium complex solution. Weigh SiO 2 3g, mixed with 0.5g BaF thoroughly, then granulated, screened 20-200 (preferably 20-60) mesh particles, added to the above solution, mixed for 1 hour while stirring and ultrasonic to form a uniform slurry. After drying in an oven at 100°C for 5 hours, calcining in a muffle furnace at 450°C for 6 hours, granulating after natural cooling, and sieving to get 20-200 mesh (preferably 20-60 mesh) particles. The composition of this catalyst is:

[0024] Ag 30%

[0025] BaF 10%

[0026] SiO 2 60%

[0027] Put the catalyst of this composition in a tubular reactor, maintain the reaction temperature at 135°C, feed hexafluoropropylene and molecular oxygen, the molar ratio i...

Embodiment 2

[0029] The preparation method is the same as in Example 1, but BaF is changed to BaCl 2 . The composition of the catalyst is:

[0030] Ag 30%

[0031] BaCl 2 10%

[0032] SiO 2 60%

[0033] Put the catalyst of this composition in a tubular reactor, maintain the reaction temperature at 120°C, feed hexafluoropropylene and molecular oxygen, the molar ratio is 1:0.5, and the reaction pressure is 2.5Mpa, the result is: the conversion of hexafluoropropylene The yield was 51.3%, and the selectivity of hexafluoropropylene oxide was 70.2%.

Embodiment 3

[0035] The preparation method is the same as in Example 1, except that BaF is changed to CsCl. The catalyst consists of:

[0036] Ag 30%

[0037] CsCl 10%

[0038] SiO 2 60%

[0039]Put the catalyst of this composition in a tubular reactor, maintain the reaction temperature at 135°C, feed hexafluoropropylene and molecular oxygen, the molar ratio is 1:0.5, and the reaction pressure is 2.5Mpa, the result is: the conversion of hexafluoropropylene The yield was 40.3%, and the selectivity of hexafluoropropylene oxide was 48.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com