Method for production and post-processing of hexafluoropropylene oxide homopolymer

A technology of hexafluoropropylene oxide and production method, applied in the field of fluorine-containing fine chemicals, can solve the problem that the molecular weight of the product is not high enough

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

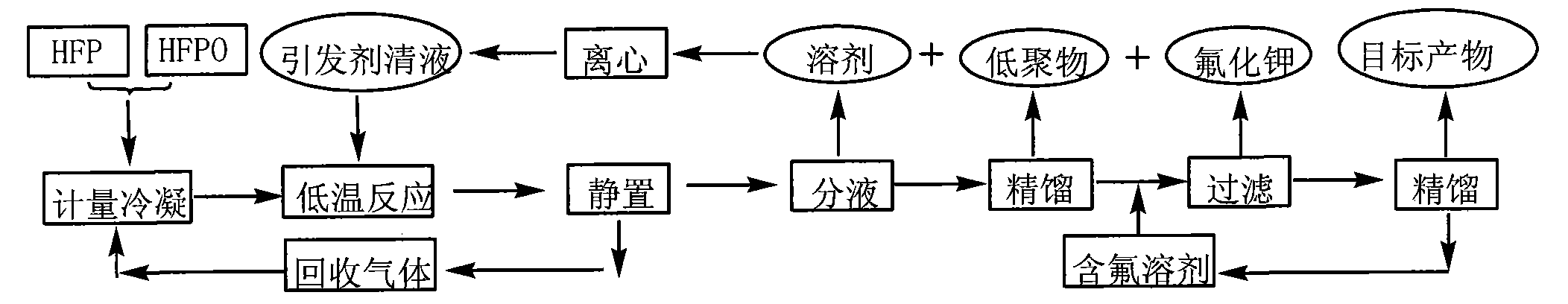

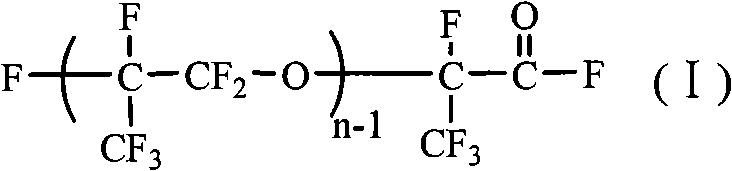

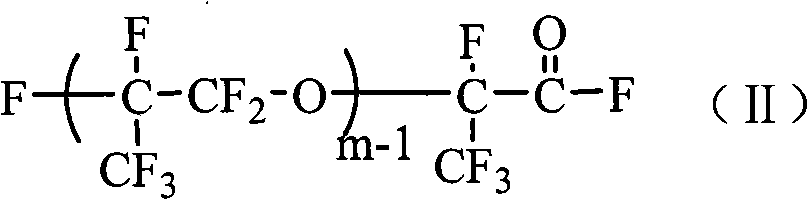

[0010] The invention provides a method for producing hexafluoropropylene oxide homopolymer, which comprises using alkali metal fluoride as a catalyst and hexafluoropropylene oxide oligomer as an initiator to trigger the ring-opening reaction of hexafluoropropylene oxide to continuously prepare The method of hexafluoropropylene oxide homopolymer shown in formula (I):

[0011]

[0012] In formula (I), n is an integer from 3 to 50, and its preparation method mainly includes the following steps:

[0013] (a), after mixing anhydrous aprotic polar solvent, hexafluoropropylene oxide oligomer and anhydrous alkali metal fluoride catalyst powder, stir vigorously for 24 hours, then centrifugally filter out initiator clear liquid; The clear solution of the agent is added to the polymerization kettle at one time and cooled to the ring-opening polymerization reaction temperature;

[0014] (b) While keeping stirring, add the mixed liquid of hexafluoropropylene oxide and hexafluoropropyle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com