Industrialized manufacturing technique for hexafluoropropylene oxide

A technology of hexafluoropropylene oxide and production process, which is applied in the direction of organic chemistry, can solve the problems of many by-products, low conversion rate of hexafluoropropylene oxide, and poor selectivity, so as to reduce the generation of by-products and improve the reaction conversion rate, the effect of increasing selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~11

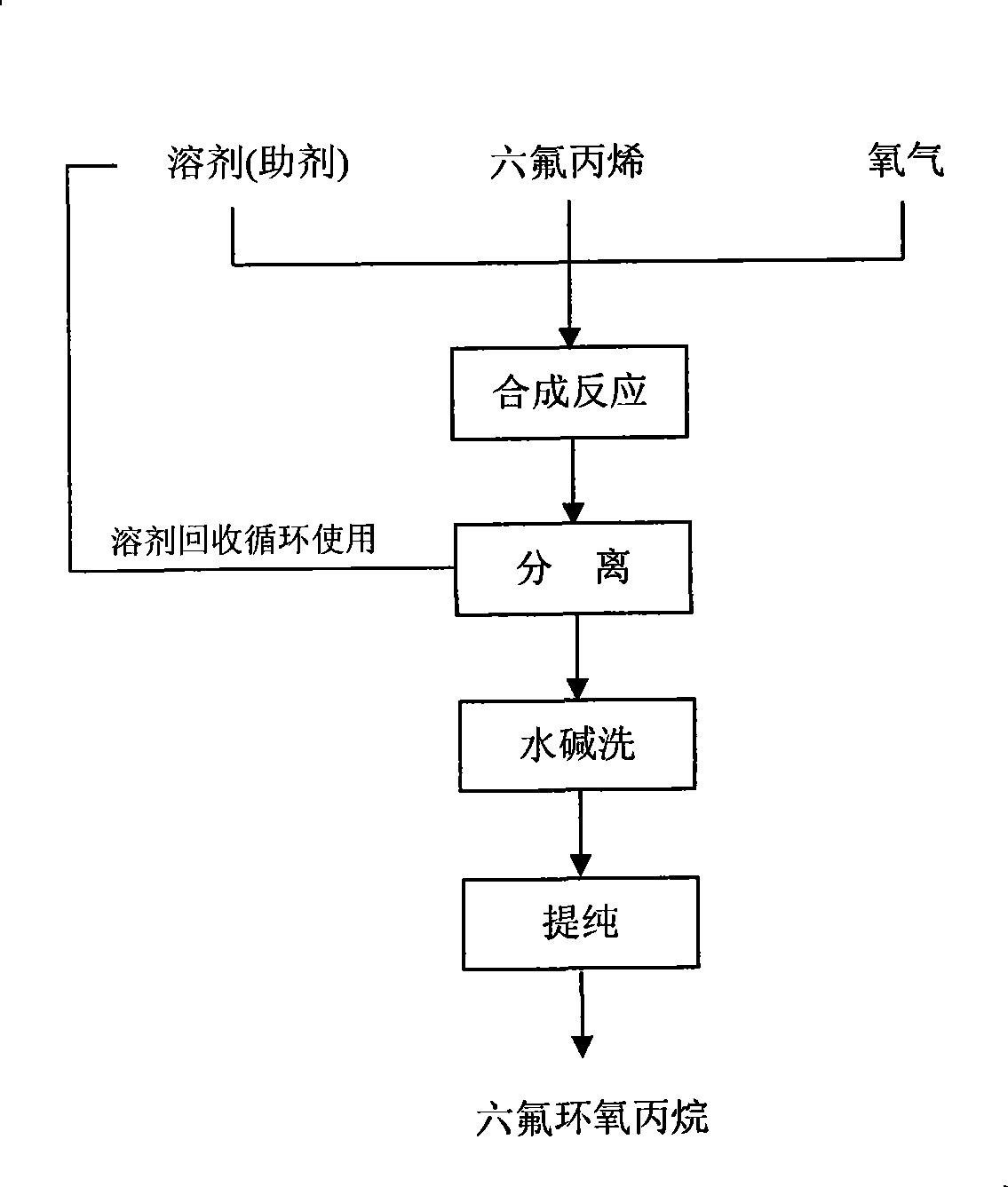

[0032] refer to figure 1 , add solvent, additives, and hexafluoropropylene into a 10L reactor, raise the temperature to a reaction temperature of 90-130°C, keep the reaction pressure at 4-5Mpa, and continuously add oxygen (the mass ratio of oxygen to hexafluoropropylene is controlled to be 1: 8-9) To the end of the reaction, after separation, washing with water and alkali, and purification, the conversion rate of hexafluoropropylene and the selectivity of hexafluoropropylene oxide are calculated, as shown in Table 1 below.

[0033] Table 1

[0034]

[0035]

[0036] As can be seen from the data in Table 1, adding an auxiliary agent in the solvent of the present invention can greatly improve the conversion rate of hexafluoropropylene and the selectivity of hexafluoropropylene oxide at the same time, especially the auxiliary agent used in Examples 5 and 8 Combination has achieved the most excellent effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com