High pure hexafluoropropylene oxide preparation method using extraction rectification

A hexafluoropropylene oxide, extractive distillation technology, applied in extractive distillation, organic chemistry, etc., can solve problems such as side reactions, environmental impact, and selectivity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

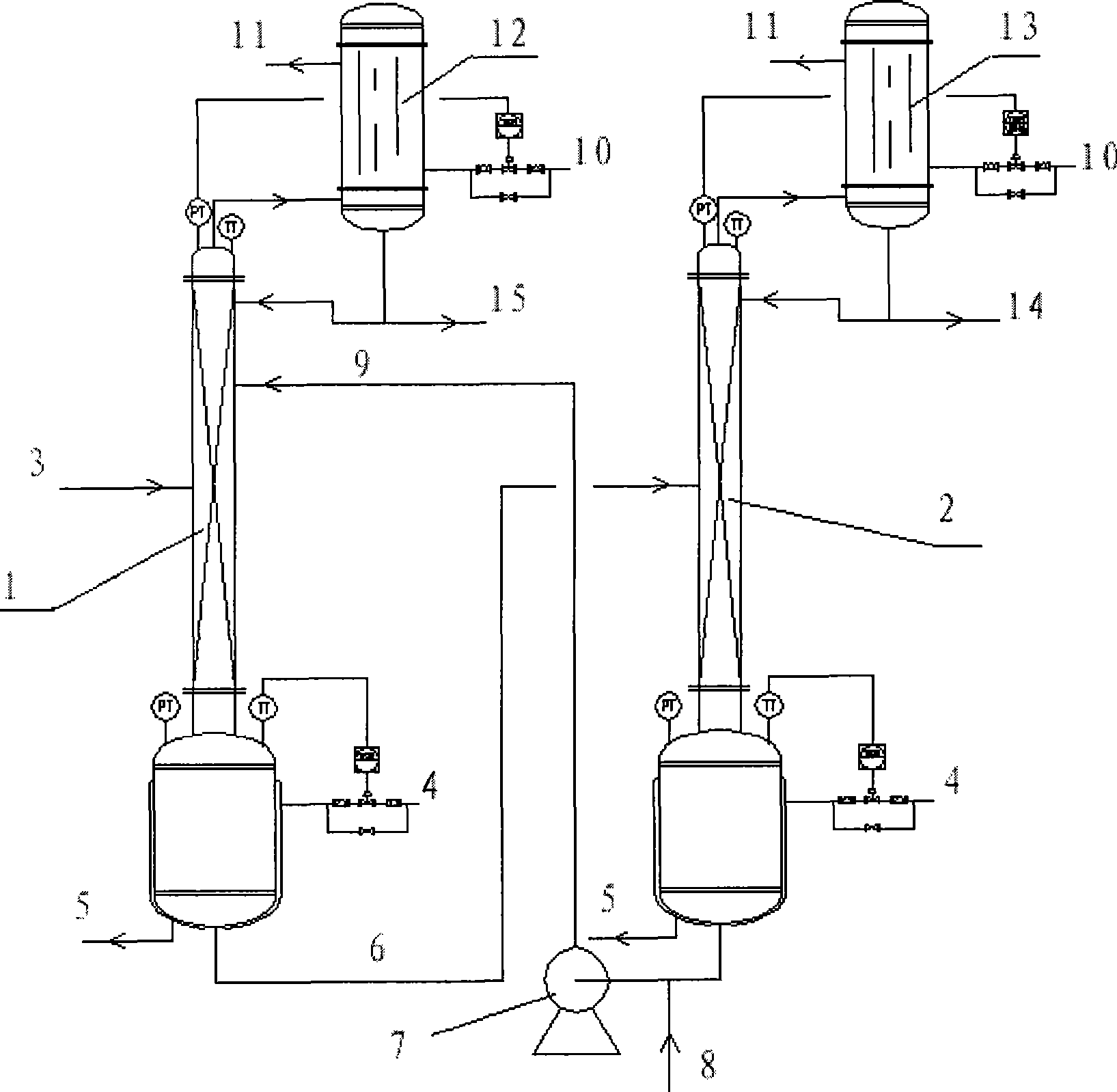

[0016] Technical scheme of the present invention is as follows:

[0017] A method for preparing high-purity hexafluoropropylene oxide by extraction and rectification, characterized in that epichlorohydrin is selected as the extraction agent, and the mass ratio of the extraction agent to the HFPO-HFP mixture feed is controlled at (1-200): 1 .

[0018] Preferably, the mass ratio of the epichlorohydrin extractant to the HFPO-HFP mixture feed is controlled at (8-100):1. The product obtained under this operating condition has the most stable quality and the highest purity.

[0019] The above-mentioned extractive distillation prepares the method for high-purity hexafluoropropylene oxide, and concrete steps are as follows:

[0020] At a temperature of 50-200°C and a pressure of 0-1Mpa (gauge pressure), the mixture of HFPO and HFP is passed into the extractive distillation column, and tetrafluorofuran is sprayed from the top of the tower, and the mixture of HFPO and HFP is fully con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com