Method of improving hydrophobic stability of nanometer array film

A nano-array and super-hydrophobic technology, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of poor stability of super-hydrophobic effect, achieve long-term stability and improve durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

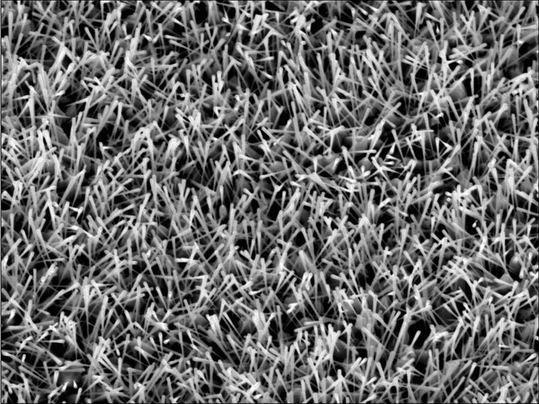

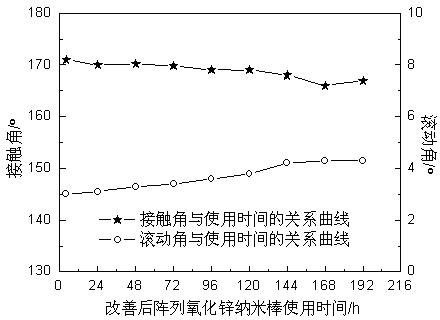

[0018] Embodiment 1: Improving the superhydrophobic surface stability of zinc oxide nanorod film

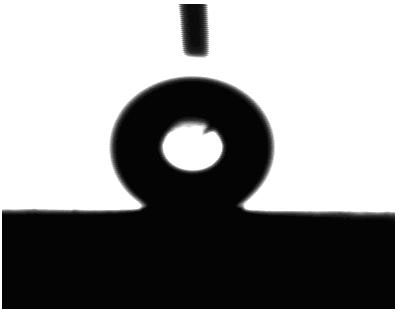

[0019] 1. A zinc oxide nanorod film with an array structure was prepared by vapor transport. In order to grasp the wettability of the surface, the contact angle of water on the surface was measured by a contact angle tester. The contact angle between the surface and water 156±2.2??, the rolling angle test results show that the rolling angle of water droplets on the surface is 8??; after 30 minutes, the contact angle and rolling angle of the surface are measured to be 121±1.4?? and 24?? ; It was observed that the water droplets completely penetrated into the gaps of the superhydrophobic array nano-films in about 20 min. The results show that the as-prepared arrays of ZnO nanorods have poor superhydrophobic stability.

[0020] 2. Clean the pollutants and adsorbates on the surface of the zinc oxide nanorod film array. The cleaning step is mainly to clean the zinc oxide nanorod fil...

Embodiment 2

[0024] Embodiment 2: Improving the superhydrophobic surface stability of carbon nanotube film

[0025] 1. A carbon nanotube film with an array structure was prepared by chemical vapor deposition technology. In order to grasp the wettability of the surface, the contact angle of water on the surface was first measured with a contact angle tester. The contact angle between the surface and water The rolling angle is 153±3.6??, and the rolling angle test results show that the rolling angle of water droplets on the surface is 7??; after 30 minutes, the contact angle and rolling angle of the surface are measured to be 117±2.3?? and 17? ?; Observe that the water droplets completely penetrate into the gaps of the super-hydrophobic array nano-film in about 25 minutes. It shows that the superhydrophobic stability of the prepared arrayed carbon nanotubes is very poor.

[0026] 2. Clean the pollutants and adsorbates on the surface of the arrayed carbon nanotube film. The cleaning step is...

Embodiment 3

[0030] Example 3: Improving the stability of the superhydrophobic surface of the porous nano-array aluminum oxide film

[0031]1. A porous nano-alumina film with an array structure was prepared by anodic oxidation technology. In order to grasp the wettability of the surface, the contact angle of water on the surface was measured with a contact angle tester. The contact angle between the surface and water 154±1.8??, the rolling angle test results show that the rolling angle of water droplets on the surface is 10??; after 30 minutes, the contact angle and rolling angle of the surface are measured to be 127±4.1?? and 19?? ; It was observed that the water droplets completely penetrated into the gaps of the superhydrophobic array nano-films in about 50 min. It shows that the superhydrophobic stability of the prepared porous nano-array alumina film is poor.

[0032] 2. Clean the pollutants and adsorbates on the surface of the array porous nano-alumina film. The cleaning step is ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com