Method for producing hexafluoropropylene oxide

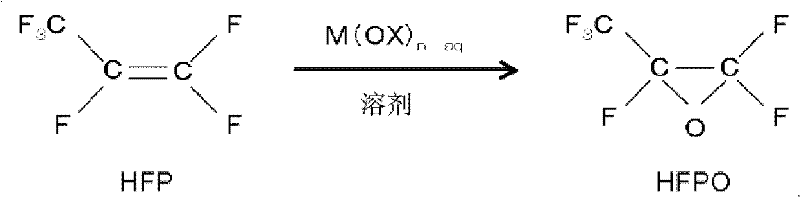

A technology of hexafluoropropylene oxide and its manufacturing method, which is applied in the direction of organic chemistry, can solve the problems of high manufacturing cost of HFPO, high cost of interphase transfer catalyst, etc., and achieve the effect of high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

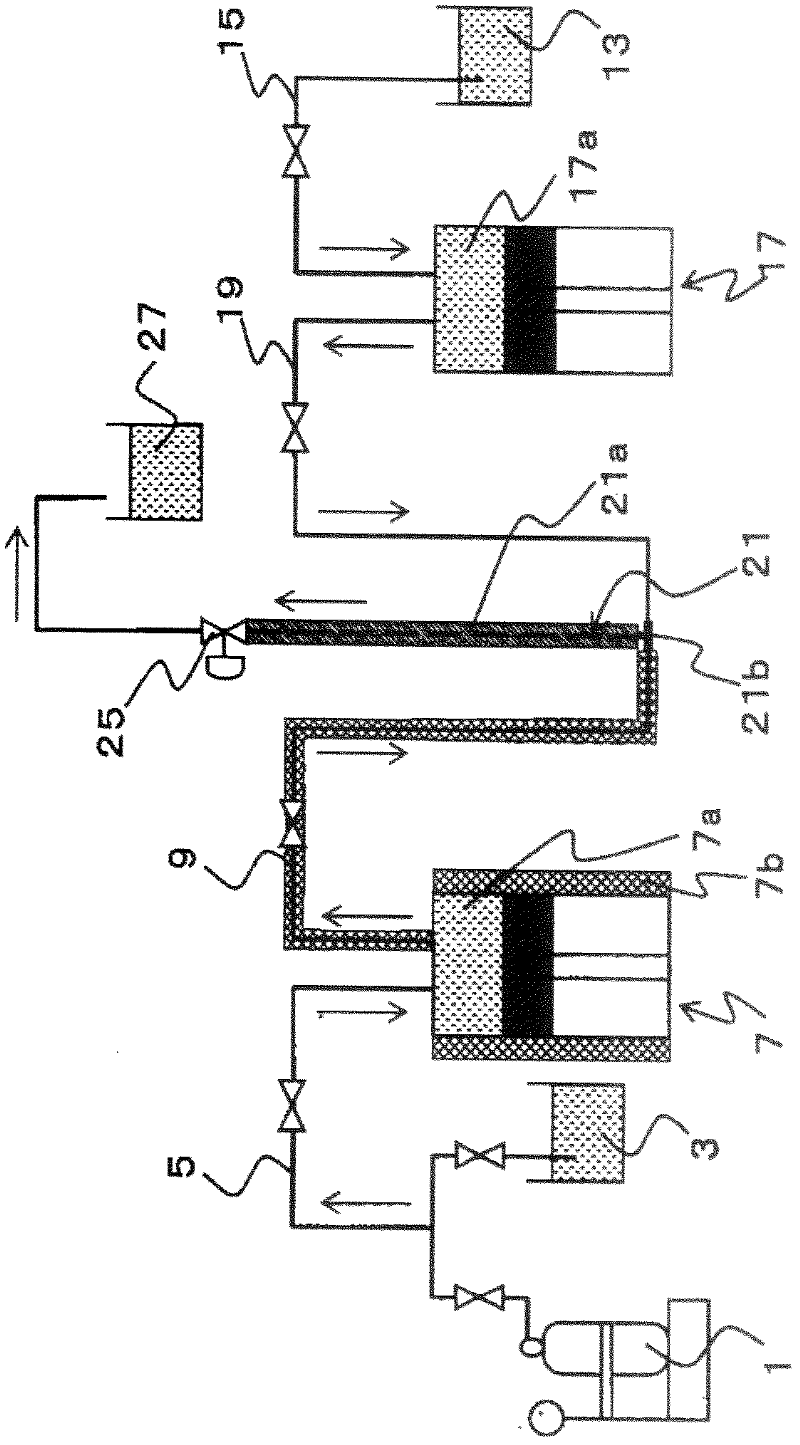

[0066] refer to figure 1 , The present embodiment relates to an example of using the inner space of the thin tube 21 (shown by a dotted line in the figure) as a tiny space. For the thin tube 21, a SUS316 tube having a nominal inner diameter of 1.0 mm and a length of 0.5 m was used. A jacket 21a is used for the thin tube 21, so that temperature can be controlled. The inlet side of the narrow tube 21 is connected to a T-shaped connector 21b made of SUS (approximately 1 / 16 inch in outer diameter, produced by Swagelok Co.), so that the organic phase and water can be combined and supplied from the pipes 9 and 19 to the thin tube 21, respectively. 2 fluids in phase. In addition, nuts etc. are suitably used for a connection part.

[0067] First, if figure 1 As shown, HFP is introduced from the HFP cylinder 1 to the pump chamber 7 a of the syringe pump 7 through the pipe 5 , and then an organic solvent (water-soluble and aprotic organic solvent) is introduced from the organic solven...

Embodiment 2 and 3

[0077] The same procedure as in Example 1 was carried out except that diglyme and N,N-dimethylformamide (DMF) were used instead of acetonitrile as organic solvents. Both diglyme and N,N-dimethylformamide (DMF) are water-soluble and aprotic organic solvents. Table 1 shows the results together.

Embodiment 4

[0079] In addition to the use of calcium hypochlorite (Ca(ClO) 2 ) to replace sodium hypochlorite (NaClO), the same operation as in Example 1. Table 1 shows the results together. In addition, in this example, in the recovered reaction mixture, CaF 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com