Pyrolysis method and device of low speed bed

A low-speed, pyrolysis technology, applied in the field of pyrolysis, which can solve the problems of difficult heat disposal and difficult hot ash distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

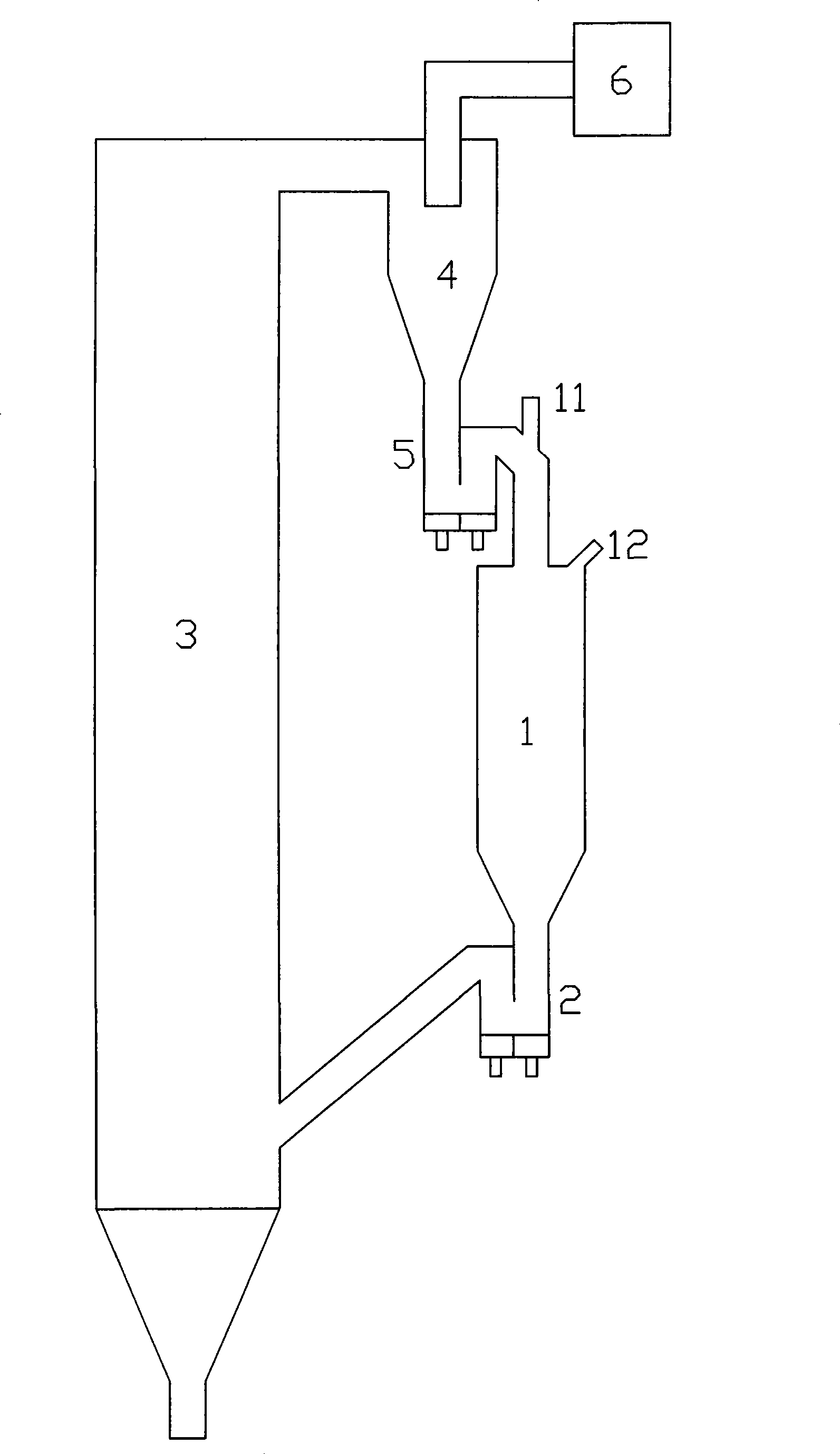

[0039] as attached figure 1 As shown, the coal undergoes pyrolysis reaction in the pyrolysis chamber to produce pyrolysis gas and semi-coke; the semi-coke is sent to the adiabatic combustion chamber for combustion, and the high-temperature materials produced by combustion are sent to the pyrolysis chamber to provide heat for the pyrolysis reaction; The combustion chamber is a circulating fluidized bed type;

[0040] Coal is added from the pyrolysis chamber; the oxygen content of the flue gas at the outlet of the combustion chamber is 0;

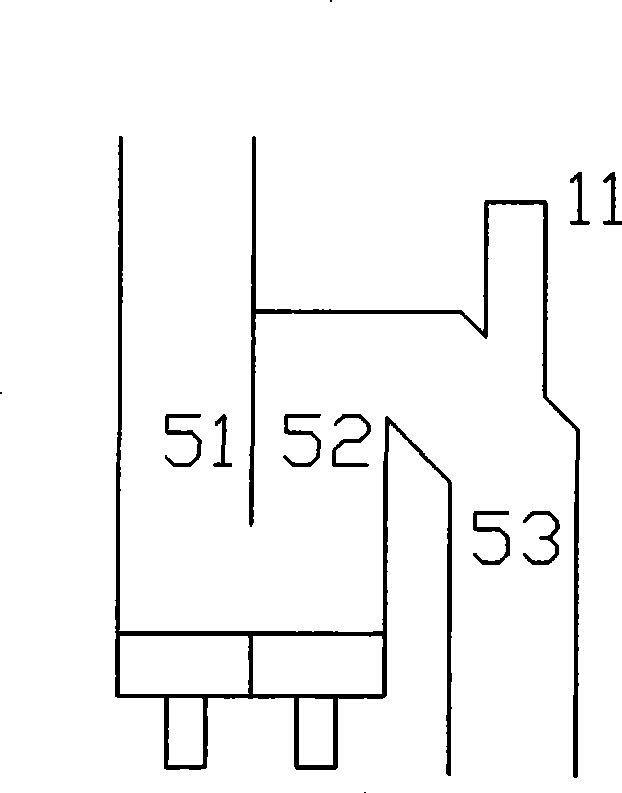

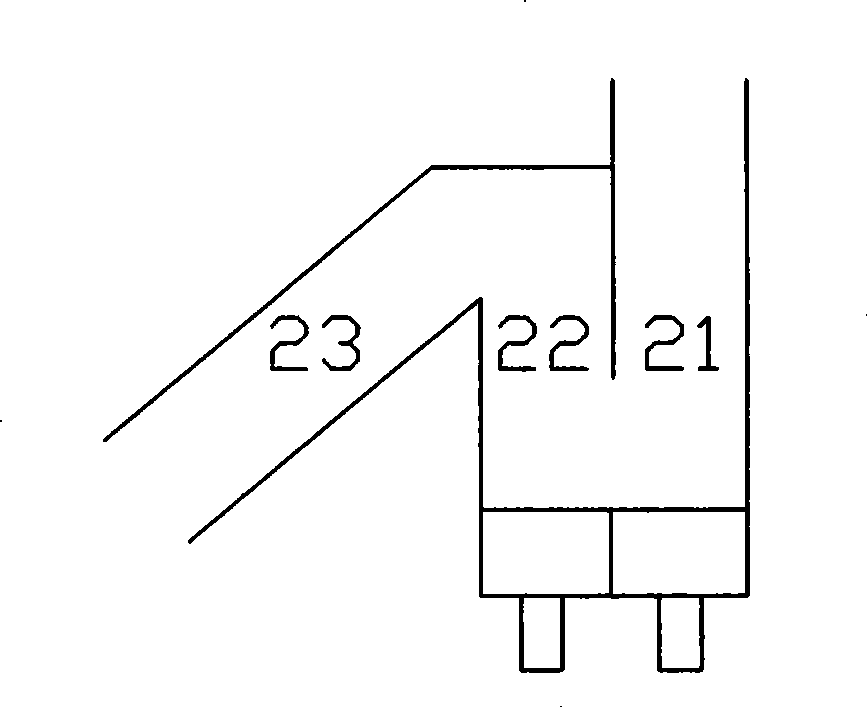

[0041] High-temperature materials enter the pyrolysis chamber from the top of the pyrolysis chamber through the feeder; semi-coke and low-temperature materials are discharged from the bottom of the pyrolysis chamber, and enter the combustion chamber through the pneumatic control valve;

[0042] The pyrolysis chamber is a low-speed bed, and the materials in the lower part flow in a downward moving bed under the action of the fluidizing wind i...

Embodiment 2

[0054] Such as Figure 4 As shown, the biomass undergoes pyrolysis reaction in the pyrolysis chamber to produce pyrolysis gas and semi-coke; the semi-coke is sent to the adiabatic combustion chamber for combustion, and the high-temperature materials produced by the combustion are sent to the pyrolysis chamber to provide heat for the pyrolysis reaction ; The combustion chamber is a circulating fluidized bed type;

[0055] Biomass is added from the pyrolysis chamber; the oxygen content of the flue gas at the outlet of the combustion chamber is 0;

[0056] High-temperature materials enter the pyrolysis chamber from the top of the pyrolysis chamber through the feeder; semi-coke and low-temperature materials are discharged from the bottom of the pyrolysis chamber, and enter the combustion chamber through the pneumatic control valve;

[0057] The pyrolysis chamber is a low-speed bed, and the materials in the lower part flow in a downward moving bed under the action of the fluidizin...

Embodiment 3

[0069] Such as Figure 5 As shown, the rubber undergoes pyrolysis reaction in the pyrolysis chamber to produce pyrolysis gas and semi-coke; the semi-coke is sent to the adiabatic combustion chamber for combustion, and the high-temperature materials produced by the combustion are sent to the pyrolysis chamber to provide heat for the pyrolysis reaction; The combustion chamber is a circulating fluidized bed type;

[0070] Rubber is added from the pyrolysis chamber; the oxygen content of the flue gas at the outlet of the combustion chamber is 0;

[0071] High-temperature materials enter the pyrolysis chamber from the upper part of the pyrolysis chamber through the feeder; semi-coke and low-temperature materials are discharged from the bottom of the pyrolysis chamber, and enter the combustion chamber through the pneumatic control valve;

[0072] The pyrolysis chamber is a low-speed bed, and the materials in the lower part flow in a downward moving bed under the action of the fluid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com