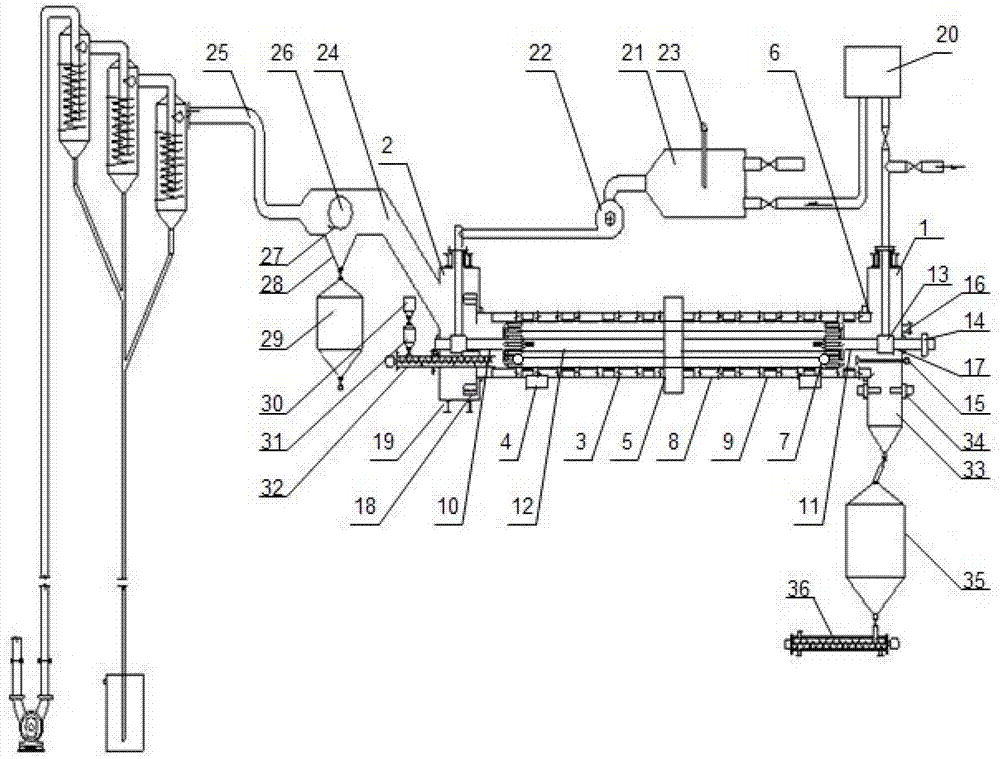

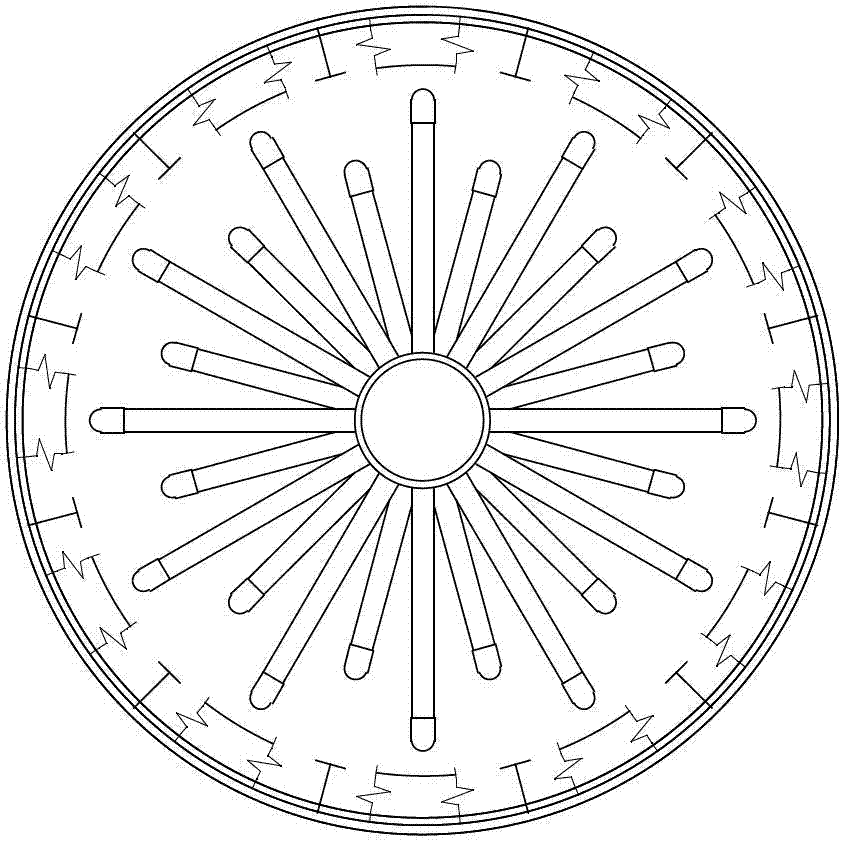

Vacuum rotary kiln and application process thereof

A rotary kiln and vacuum technology, applied in the field of vacuum rotary kiln and its application technology, can solve the problems of flying dust, short residence time of ore materials affecting roasting quality, etc., and achieve the effect of expanding heat transfer area, ensuring strength and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] It is used for vacuum dehydration of coexisting minerals of pyrite and pyrite.

[0041] Maintain a stable temperature of 300°C during dehydration to avoid decomposition of pyrite and pyrite due to occasional overheating. Due to the vacuum, the dehydration speed is faster than normal pressure at the same temperature; due to the rapid tumbling and dispersion of the material, the moisture inside the material escapes quickly; the temperature of 300 ° C is much higher than the boiling point of water, and the surface of the material It is easier for water to leave the material; the forward and reverse operation is adopted to make the material turn over more thoroughly, so the moisture content of the material after dehydration is less than 0.5%. The equipment is equipped with three water vapor cyclone condensers, blowing cold air through the coil pipes, expanding the cooling area, and making the evaporated water vapor leave the surface of the material faster, so the vacuum deh...

Embodiment 2

[0043] The vacuum rotary kiln described in Example 1 is used for roasting desulfurization and arsenic removal of refractory gold ores containing arsenic and sulfur.

[0044] Refractory gold ores are mostly flotation ores with a high water content, and they are also minerals where pyrite and pyrarsenite coexist. The method described in Example 1 needs to be used for vacuum dehydration.

[0045] The arsenic-bearing gold ore in a certain place contains Au80g / t, As20%, S20%, and the minerals are mainly pyrite and pyrite. For this kind of gold ore, after the first step is vacuum dehydration at 300°C, enter the second step of 500°C vacuum thermal decomposition pyrite desulfurization, use wind condensation drum to recover elemental sulfur, and the third step enters 750°C vacuum thermal decomposition of sulfur arsenic Arsenic removal from iron ore uses an air-cooled drum to condense and collect metallic arsenic at a temperature of 400°C. The volatile recovery rate of arsenic reaches ...

Embodiment 3

[0048] The vacuum rotary kiln described in Example 1 is used for roasting, desulfurization, arsenic and decarburization of extremely refractory gold ores containing arsenic, sulfur and carbon

[0049] The first step is vacuum dehydration, the second step is vacuum desulfurization, and the third step is vacuum arsenic removal. Since the first three steps are all carried out under vacuum, the C in the gold mine has not been burned, and the remaining FeS has not been decomposed. Then go to the fourth step to add a proper amount of pyrite for sulfuric acid production at 850 ° C. Under normal pressure, carry out airtight desulfurization and decarburization with oxygen-enriched roasting, and the produced SO 2 sulfuric acid. The calcined sand produced is conveyed and cooled by an air-cooled screw machine. The cooled calcined sand is used for wet gold extraction, and the hot air generated by the cooled calcined sand is returned for controlled vacuum dehydration at 300°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com