Solid fuel drying equipment

A technology of solid fuel and drying gas, which is applied in the directions of drying solid materials, heating to dry solid materials, and drying gas arrangement. Effects of contact time, ease of particle backmixing, and reduced bed pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

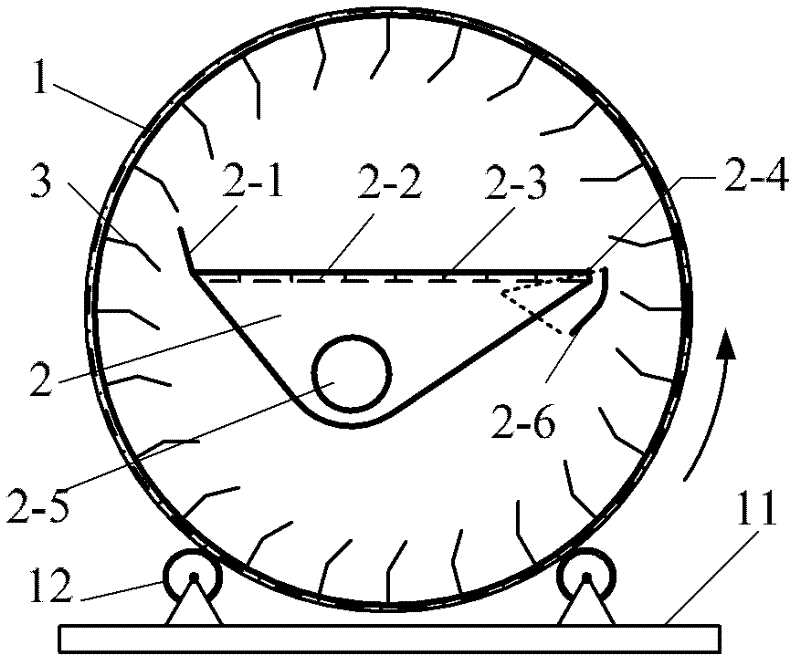

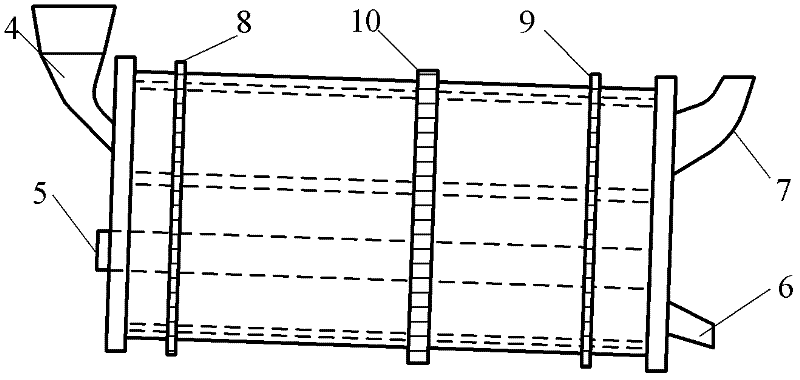

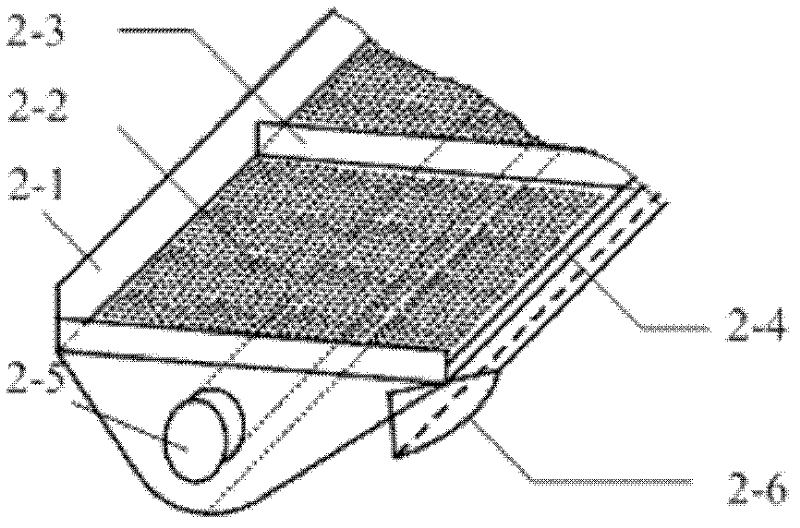

[0024] Such as figure 1 and figure 2 The rotary fluidized bed shown is mainly composed of a rotary drum 1 and a fluidized bed 2 . The inner wall of the drum 1 is provided with a lifting board 3 with a fixed knuckle angle of 120°, which is used to repeatedly transfer the lignite particles falling to the bottom of the drum to the fluidized bed. One end (inclined high end) of the drum is provided with a material inlet 4 and an air inlet 5, and the other end is provided with a material outlet 6 and an air outlet 7. The rotating drum shell is welded with transmission gears: driven gear 8, driven gear 9, driving gear 10, wherein driven gear 8 and driven gear 9 are connected with gear 12 fixed on the base plate 11. The driving gear 10 is connected with the transmission gear (not shown) of the motor system to drive the drum 1 to rotate at a certain speed. Rotating cylinder 1 is placed obliquely, and the inclination angle is 8°, and the inclination angle of rotating cylinder 1 can ...

Embodiment 2

[0027] The rotary drum is placed obliquely, the inclination angle of the rotary drum is 10°, the folded flight board on the inner wall of the drum is a movable folding angle, and the folding angle of the folded flight board is 90°, and the fluidized bed is set at intervals of 30cm along the axis of the drum. Partition, the height of the partition is 5cm, a baffle with a height of 100cm is set at one end of the fluidized bed, and the inclination angle of the baffle is 160°, and an overflow weir is provided at the other end of the fluidized bed, and the height of the overflow weir is 5cm , the temperature of the drying gas is 120°C. All the other are with embodiment 1.

Embodiment 3

[0029] The rotary drum is placed obliquely, the inclination angle of the rotary drum is 5°, the folded flight board on the inner wall of the drum is a fixed folding angle, and the folding angle of the folded flight board is 180°, and the fluidized bed is set at intervals of 150cm along the axis of the drum. Partition, the height of the partition is 30cm, a baffle with a height of 80cm is set at one end of the fluidized bed, the inclination angle of the baffle is 90°, and an overflow weir is provided at the other end of the fluidized bed, and the height of the overflow weir is 30cm , the temperature of the drying gas is 250°C. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com